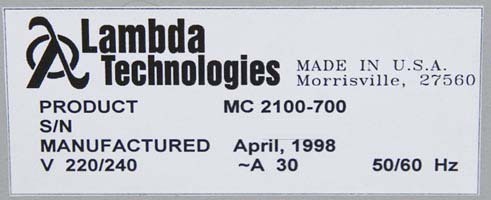

Used LAMBDA TECHNOLOGIES MICROCURE 2100 #64770 for sale

URL successfully copied!

Tap to zoom

ID: 64770

Vintage: 1998

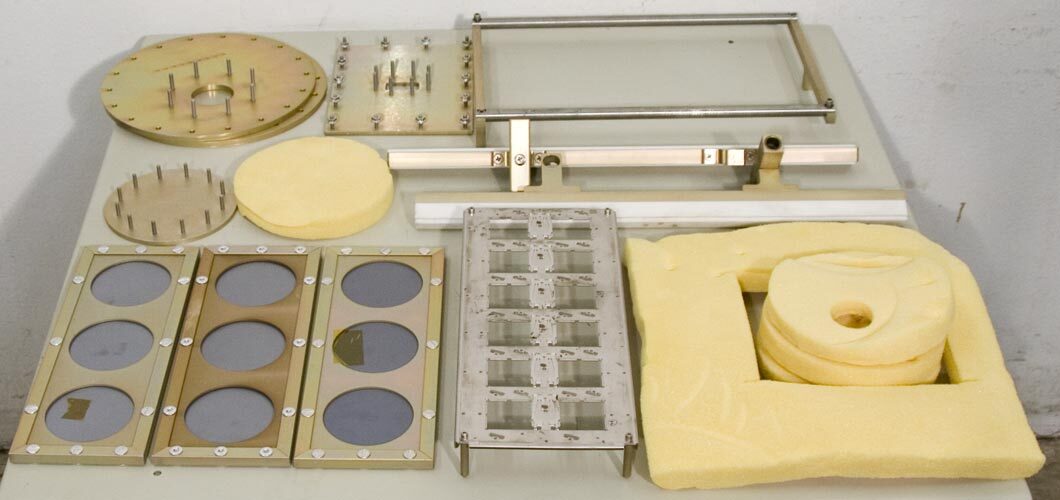

Variable frequency microwave oven / Furnace

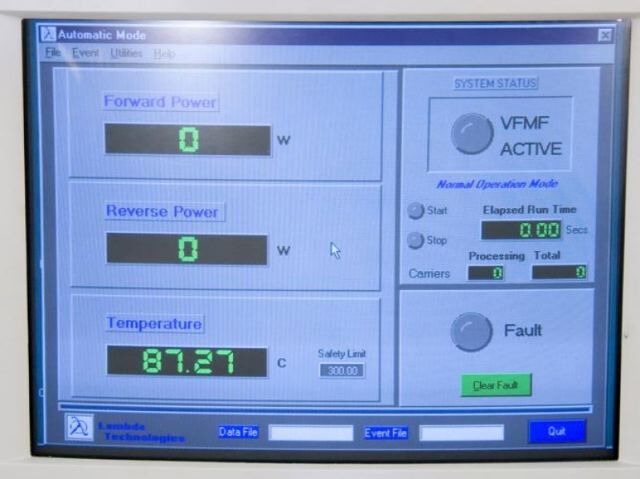

Controller / Processor software revision: 305

Temperature monitor: RAYTEK Thermalert 30

Fiber optic thermometer: NORTECH FIBRONIC NoEMI-TS Series

Compact disc with MicroCure:

Software version 3.05

Compact disc with National NI-DAQ software

(1) MC V.3.05 Disk 2

(1) Calibration backup disk

TWTA Installed:

Manufacturer: CPI

CE Marked: Yes

Software version: 1.06F

Type: 600 / 700 W, CMPA

Beam run time: 102 Hours

Heater run time: 4756 Hours

Sweep rate adjust: 0.1 to 60 seconds

Temperature control: IR, non-contact, to 385°C

Temperature monitor: Up to 4 channels, to 265°C

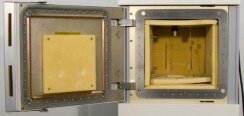

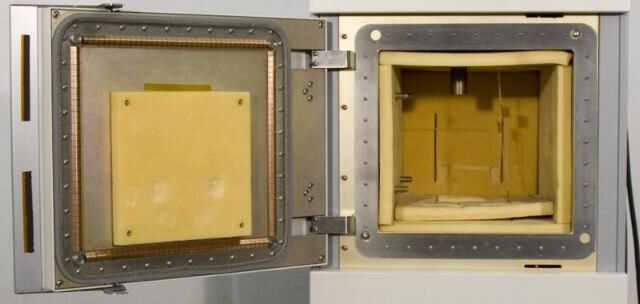

Cavity size: 14" H x 15" W x 19" D

Frequency range: 5.8 to 7.0 GHz

Microwave power: 400, 700 Watts

Power requirements: 220/240 V, 50/60 Hz, ~ 30 A

1998 vintage.

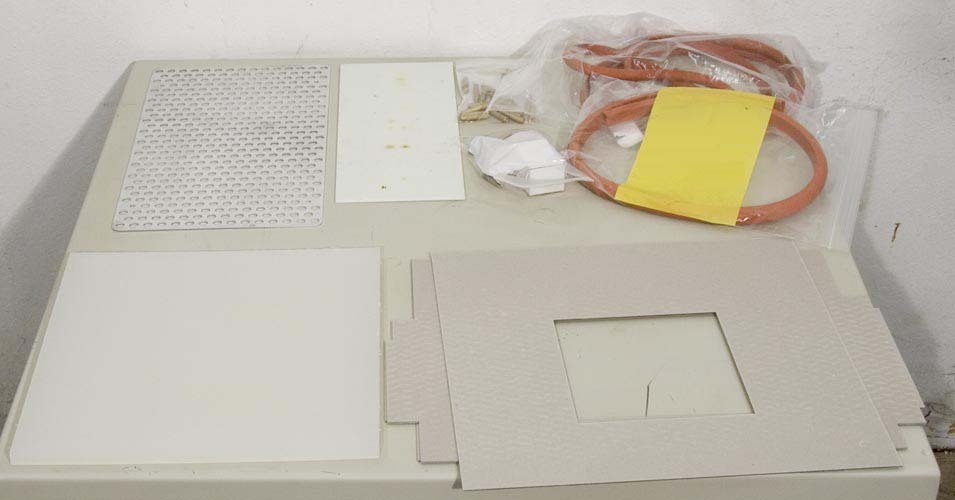

LAMBDA TECHNOLOGIES MICROCURE 2100 is an efficient and reliable industrial-grade oven/furnace designed for precise heating and curing of a wide variety of materials and substrates. This oven/furnace is an all-in-one workhorse which combines a robust design with advanced technology to ensure consistent results every time. MICROCURE 2100 is constructed with durable, high-quality stainless steel and is designed to withstand temperatures up to 1100°C (2012°F). It features intelligent controllers, advanced data management capabilities, and programmable modes to ensure precise heat profiles and accurate temperature readings. Additionally, the oven/furnace incorporates a high-density insulation layer which reduces heat loss and increases process efficiency. LAMBDA TECHNOLOGIES MICROCURE 2100's ergonomic design provides an accessible workspace, making it easier for users to operate the oven/furnace. Its accessible control panel and intuitive user interface allow for simple control and adjustment of heating profiles. Additionally, the programmable modes make it easy for users to create their own heating profiles for repeatable and consistent heating. The oven/furnace's internal chamber is designed to maximize safety, prevent contamination, and reduce the risk of fire. It utilizes an advanced airflow management system that uniformly distributes heat in a 360 degree fashion, which reduces the chance of hot spots. Furthermore, the embedded safety sensors monitor the internals of the oven/furnace to prevent overheating and ensure stable operational temperatures. MICROCURE 2100 oven/furnace utilizes advanced data management software to ensure process repeatability and accuracy. Records of all process data are saved, allowing the user to monitor, compare, and analyze the data. Additionally, this software provides real-time feedback on the process, allowing users to make corrections quickly and accurately. LAMBDA TECHNOLOGIES MICROCURE 2100 is the perfect oven/furnace for a variety of applications, offering precise and consistent temperature control, advanced data management capabilities, and a robust design that is built to last. It is a reliable and efficient solution for materials and substrate heating and curing.

There are no reviews yet