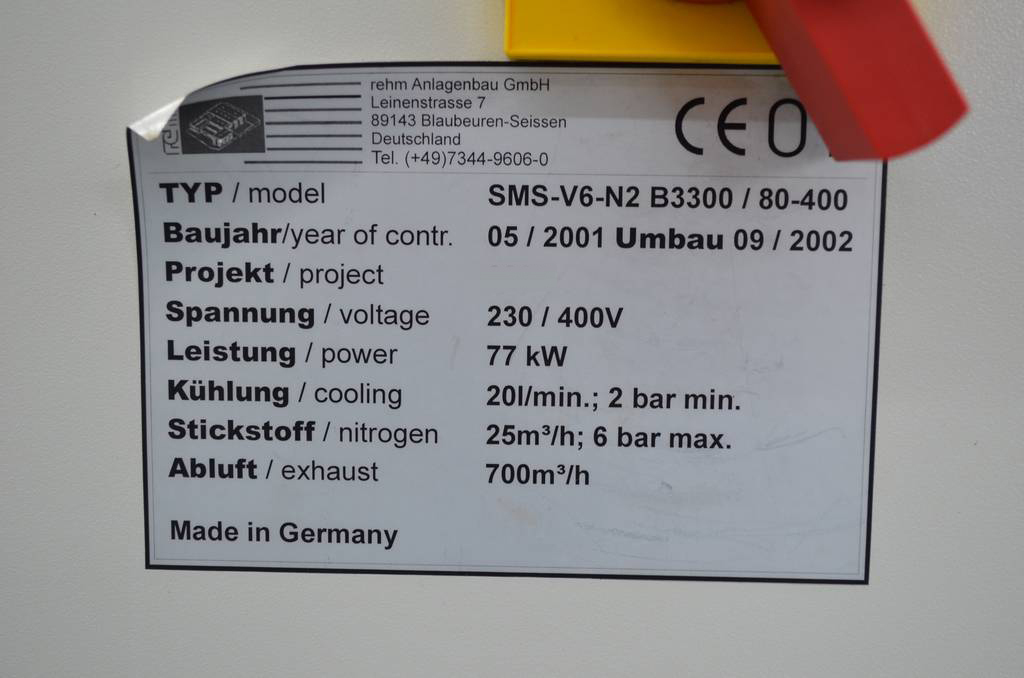

Used REHM SMS-V6-N2 B3300/80-400 #9050538 for sale

URL successfully copied!

Tap to zoom

ID: 9050538

Oven

Reflow heater

Brazing furnace

Cooling: 20 L/min, 2-bar/min

Nitrogen: 25 m3/h, 6-bar max.

Exhaust: 700 m3/h

230/400 V, 77 kW

2001 - 2002 vintage.

REHM SMS-V6-N2 B3300/80-400 is a semiconductor oxidation furnace used to create thin dielectric layers such as silicon dioxide, silicon nitride, etc. It is capable of achieving maximum temperatures ranging from 800°C to 1400°C with uniformity and accuracy. It uses dual frequency induction heating, which offers flexibility of choice for the optimum processing temperature. The oxidizing atmosphere within the furnace is configured using a combination of nitrogen and oxygen, with up to 100% nitrogen being available if required. This environment can be adjusted to suit the user's specific process requirements, enabling efficient and repeatable processing to be achieved. The unit is equipped with a comprehensive range of temperature controls, ensuring precise temperatures and uniform, repeatable results. These include a fully computer-controlled data logging equipment with up to 4 profile programs for stored data, automatic overtemperature protection system and a manual overheat protection facility. In addition, the furnace allows for independent oven control over different sections for graduated temperature profiling of a wafer. The integrated 6-stage filter unit ensures that the atmosphere inside the furnace is free of particulates, and a microprocessor-controlled air pressure monitoring machine permits dynamic control of the atmosphere. The fabric of the furnace is rated at 0.5 inches thick, so as to prevent heat loss and maintain a consistent temperature inside the furnace, even under high temperature operation. The furnace is constructed from heavy-grade stainless steel, which is both durable and corrosion-resistant, making it ideal for numerous industrial purposes. The inert gas used inside the furnace is supplied to the chamber via a process gas switch (PGS). The furnace also includes an air pressure monitor to ensure that the desired pressurization is achieved. The furnace's control module is fitted with an 8.4" touch screen LCD display, which allows the user to set up and track programs, control parameters such as temperature, pressure, and gas mix, as well as monitor process progress. A USB port is also fitted for data backup, tool diagnostics, and software updates. The installation can be controlled remotely, using Ethernet or RS232/RS485/USB interface. Overall, REHM SMS-V6-N2 B3300/80-400 is an advanced, high-precision furnace, suited to oxidation and diffusion of semiconductor wafers. Its flexible design, comprehensive control asset, and accurate temperature monitoring capabilities, make it an important tool for a whole range of industries.

There are no reviews yet