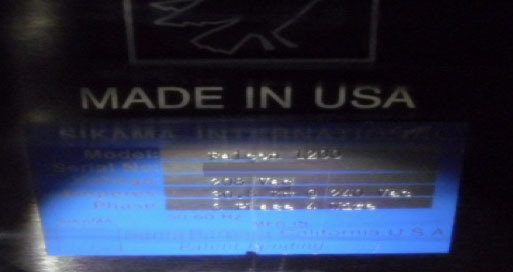

Used SIKAMA Falcon 1200 #9067894 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9067894

Reflow furnace

In Loadport, 8"-12"

Flux coat

Reflow: (8) Zones: (7) Hot, (1) Cold

Wafer buffer, 8"-12"

Out Loadport, 8"-12"

(2) Flux box

(1) N2 Gas (reflow): 2.5~5.0kg/cm2, 250 slm(L/min), 1/2" NPT, SS316 BA/EP, O2: < 10ppm

Static pressure: 6.0 kg/cm2

Mass flow rate: 250.0lpm, 8.8cfm

(4) N2 Gas (ICS412): Chemical driving 1/4" NPT, SS316 BA/EP

Static pressure: 40.0psi

(2) Compressed dry air (clean), Sikama reflow: Walking beam reserve 1/4", SW/NPT , > 60 psi, consuming :N/A

Static pressure: 60.0psi

(1) Compressed dry air (clean), IC412 Coater: CylinderDriving. 1/4",SW/NPT , > 80 psi, consuming :N/A

Static pressure: 5.0 kg/cm3, 80.0psi

(1) Facility vacuum system, IC412 Coater: Wafer Holding. 1/4" OD, SW/NPT, > 25” Hg, consuming :N/A

Static pressure: 25.0Hg

≦26.6inHgV

(2) Facility vacuum system, Robot: Wafer Holding Check. 1/4" OD, SW/NPT, > 25” Hg, consuming :N/A

Static pressure: 25.0Hg

≦26.7inHgV

(1) Process cooling water (inlet): PCW/CT water(Supply ) 2.0~3.5 kg/cm2, 1/2" NPT, 2.0~8.0 slm, 6 ~ 25 degree C(Process dependent), <0.5 Mom

Static pressure: 3.5kg/cm2, 45.0psi

Mass flow rate: 8.0lpm, 0.3cfm

(1) Process cooling water (outlet): PCW/CT water(Return) 2.0~3.5 kg/cm2, 1/2" NPT, 2.0~8.0 slm, 6 ~ 25 degree C(Process dependent), <0.6 Mom

Static pressure: 3.5kg/cm2, 45.0psi

Mass flow rate: 8.0lpm, 0.3cfm

(2) Inorganic exhaust, (1) Reflow: Flexible or tractable tube is required, Manual adjusted valve/blade is recommended, 4" OD, Meter required, Outlet Temp is 150℃ (process dependent)

(1) Inorganic exhaust, (1) Coater: 2" ID, flange, flexible tube, Solvent Exh, > 10 psi

Static pressure: 1.0

(1) Inorganic drain: (1) Coater: 1" ID, flange, flexible tube, Solvent drain

Vibration.

SIKAMA Falcon 1200 is a premium electric furnace designed for the industrial heating, annealing, and smelting of metal parts and components. The furnace is equipped with a sturdy and durable construction, and can withstand high temperatures for improved performance. It is powered by a 1200 watt, three-phase industrial heating system that runs on any standard three-phase input voltage. The furnace has a rugged steel housing with a protective ceramic roller covering for improved insulation and temperature control. The furnace also features an emergency stop switch, a double-layer thermal shield, and a heat-resistant casing. It is designed to ensure safe operation even at its maximum operating temperatures. The furnace can reach temperatures of up to 1600°C. Falcon 1200 offers a wide range of heating options, including convection, radiation, and even vacuum-sealing. It also features an electronic temperature control system that offers precise temperature control and regulation without the need for manual adjustment. The furnace has an adjustable timer with up to 99 hours of pre-set programming to reduce process variations. The temperature is also displayed on an LCD screen on the front of the unit. SIKAMA Falcon 1200 is a versatile oven that can be used to heat metals, glass, ceramics, and other materials. It is designed to perform a variety of tasks, including preheating, annealing, and smelting. It is also suitable for laboratory experiments and other heating operations. It can also be used for melting down metals to create slag and for treating objects for purposes such as thermal hardening. Falcon 1200 is an efficient and reliable furnace that offers a wide range of features and capabilities. It has a durable construction that can withstand extreme temperatures and is suitable for industrial and laboratory use. It also provides precise temperature control and temperature displays. SIKAMA Falcon 1200 is a great choice for applications requiring consistent results with repeatable temperatures.

There are no reviews yet