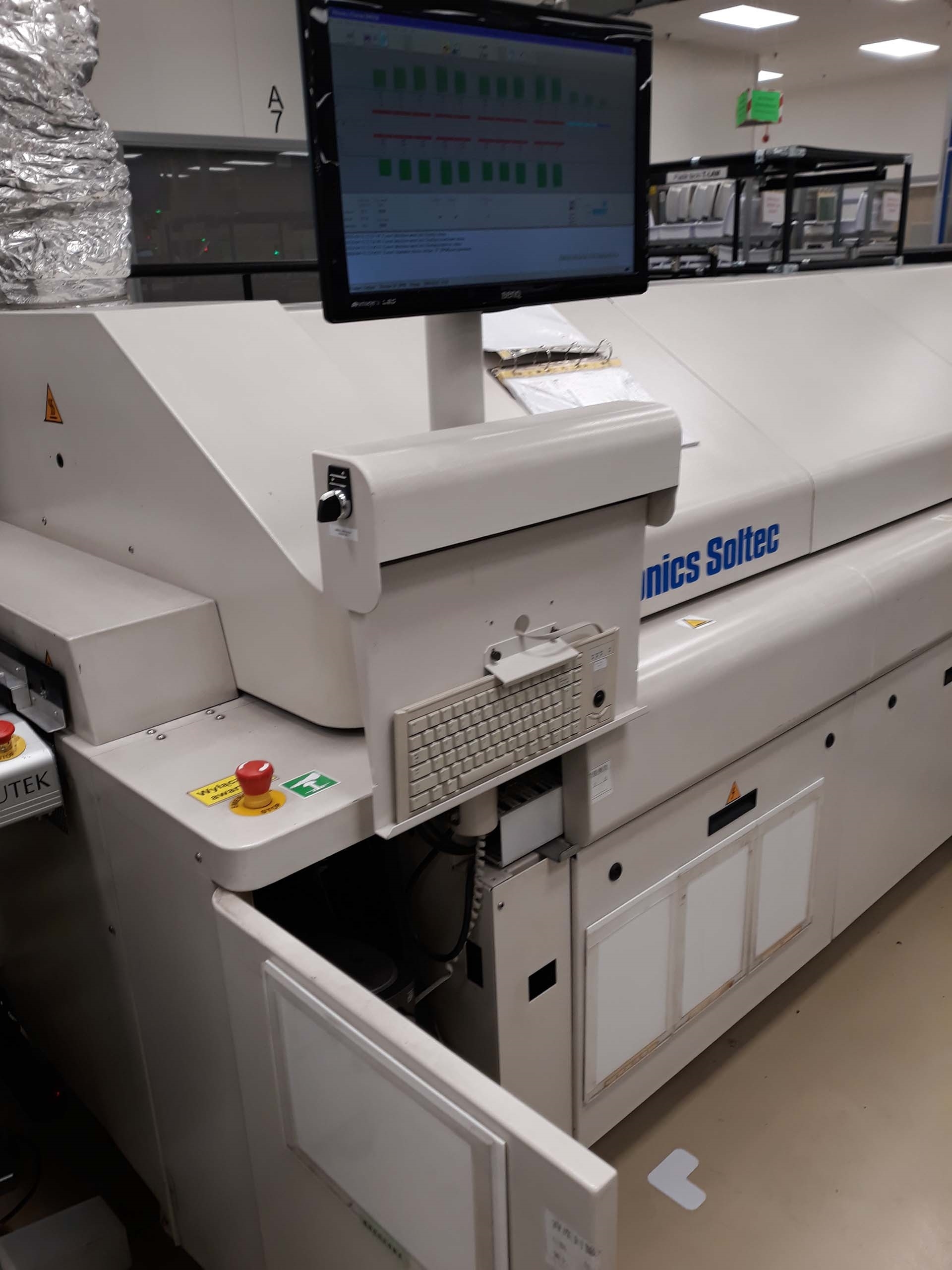

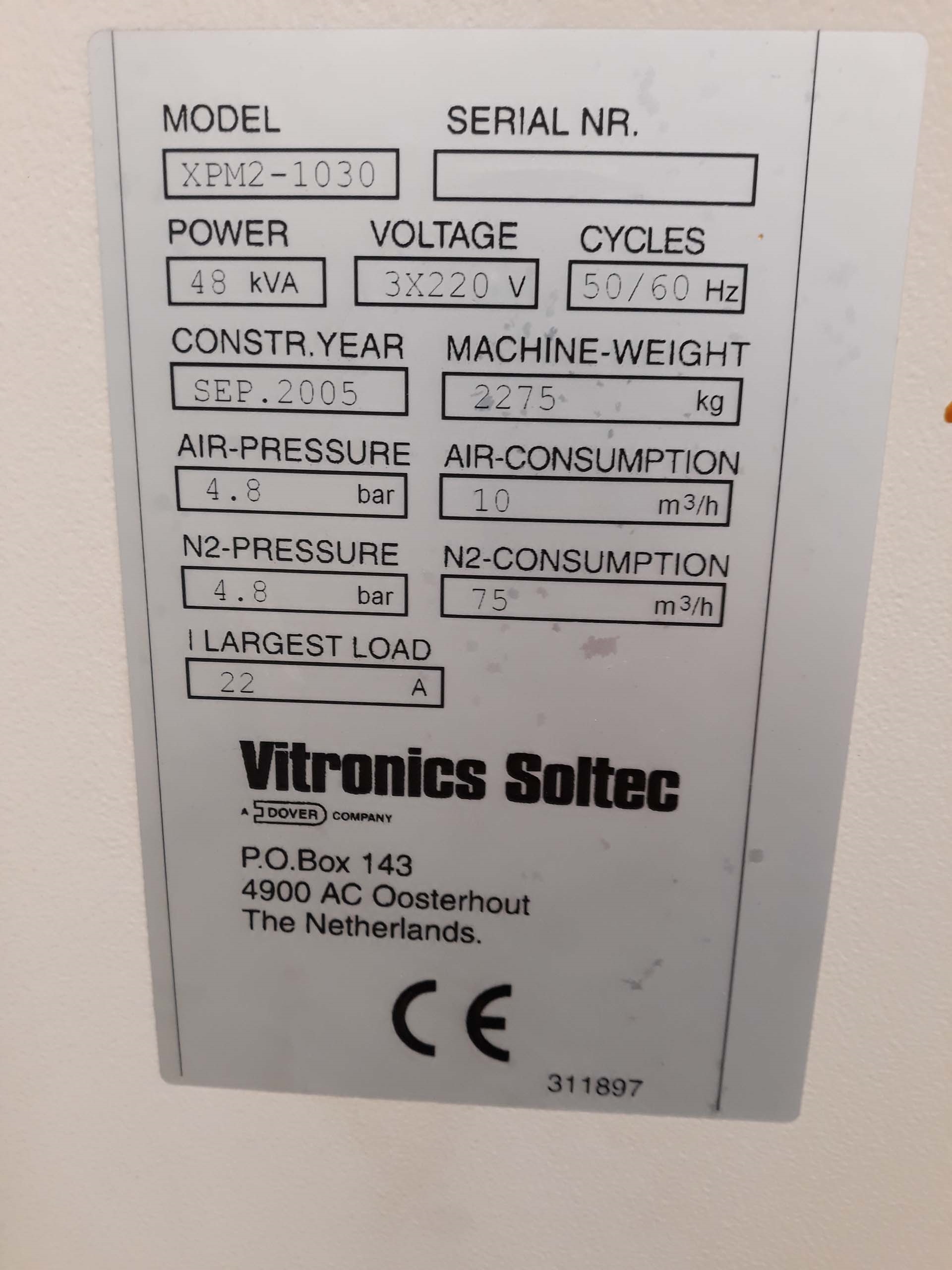

Used VITRONICS SOLTEC XPM2-1030 #9279962 for sale

URL successfully copied!

Tap to zoom

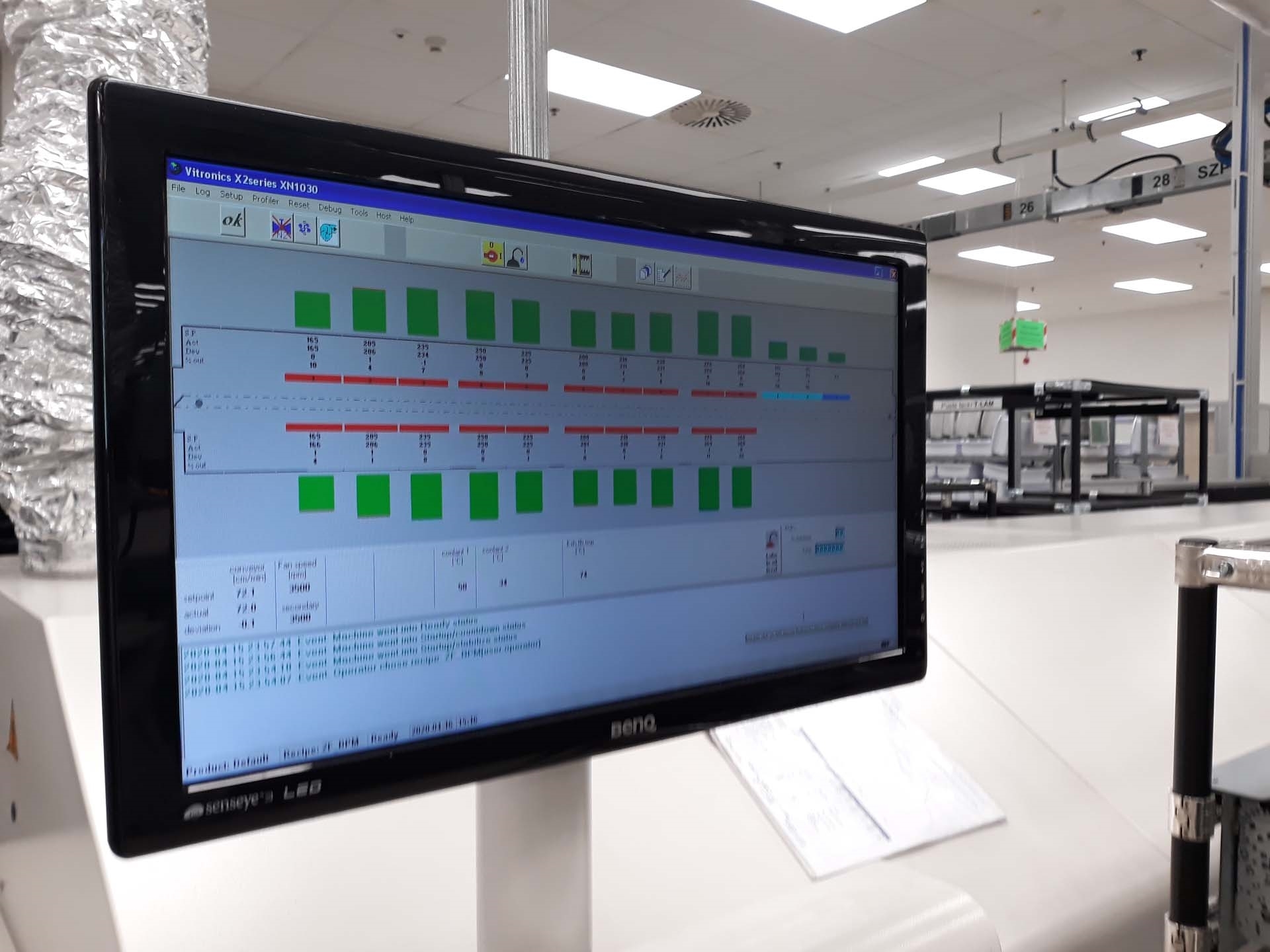

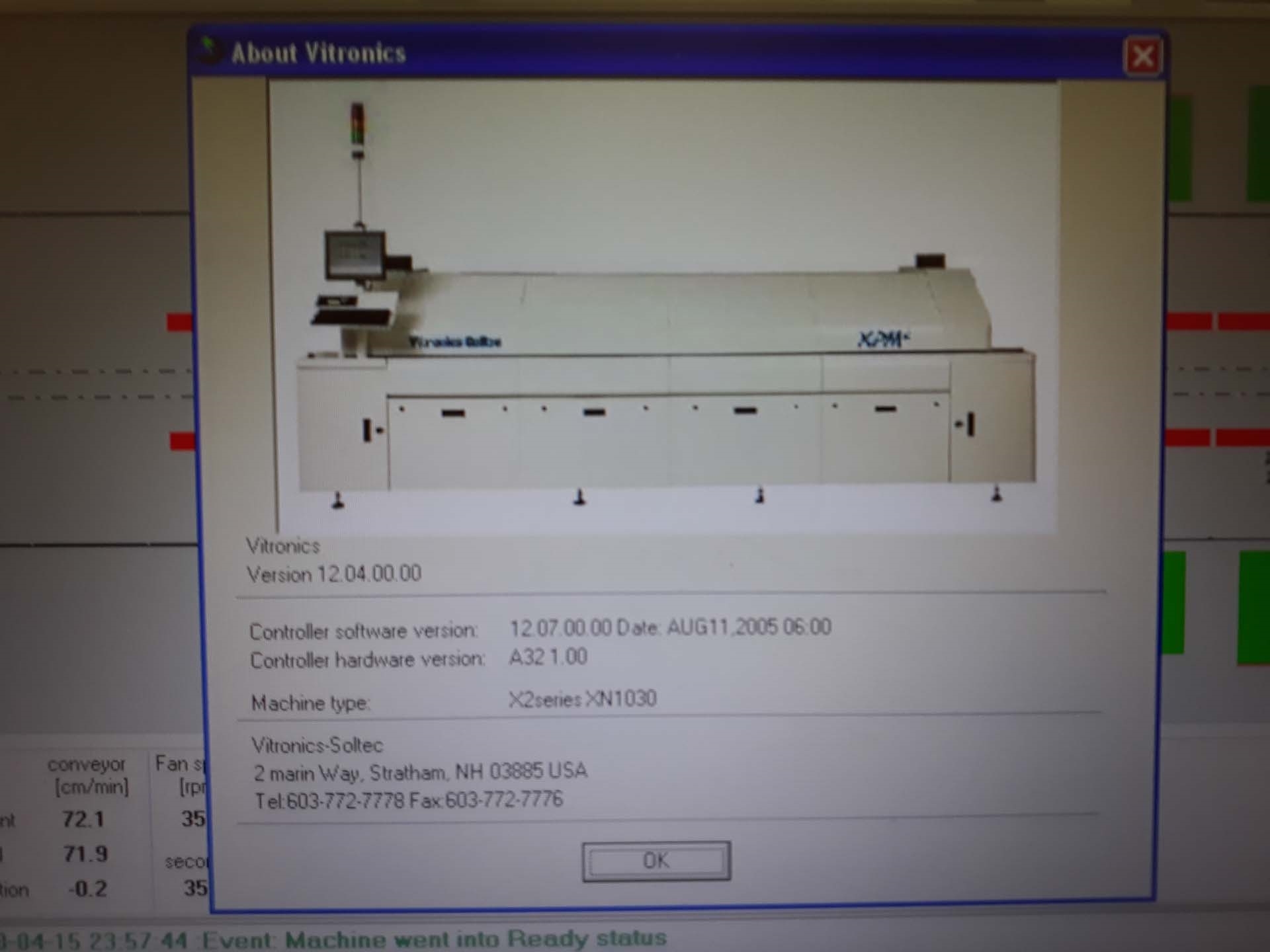

VITRONICS SOLTEC XPM2-1030 is an advanced oven / furnace specially designed for soldering and curing applications in the production of printed circuit boards (PCBs). This highly sophisticated machine boasts a range of features to provide high levels of process control and quality assurance for production demand. VITRONICS SOLTEC XPM2 1030 is a high performance machine with dual vertical convection air delivery that ensures fast heat-up and cooling rates. Its chamber size is capable of accommodating residential and industrial-size PCBs, resulting in highly repeatable temperature uniformity. The unit's temperature control provides precise temperature profiling, with a minimum 0.1°C resolution and ±2°C uniformity. This ensures consistent and high-quality temperature control throughout the entire PCB, eliminating the need for manual processing or over-processing of components. XPM 2 1030 is equipped with a variable-speed nitrogen/air circulation system that adjusts the airflow rate for optimized temperature uniformity. This further enhances the machine's temperature uniformity and helps to ensure a quality PCB solder joint. Further aiding process control is the touch screen interface that provides quick access to pre-set oven profiles, as well as the ability to create and save new settings. XPM2 1030 is also equipped with a series of alarms and indicators to alert the user to the completion of the heating process and any process-related errors. This helps to ensure that the machine is operating effectively and that critical temperature targets are met. VITRONICS SOLTEC XPM 2 1030 also features high-powered SMLCD (super-miniature liquid crystal display) illumination to ensure that all components on the PCB are clearly visible and optimally heated. This feature greatly reduces the risk of any components going undetected, thus improving the quality assurance process further. Finally, XPM2-1030 is equipped with an 'on-line help' feature which outlines the system components and indicates how these should be used. This feature is designed to simplify the set-up and operation of the unit, thus eliminating the need for costly training or manual labor. The powerful combination of features provided on VITRONICS SOLTEC XPM2-1030 makes it an ideal choice for any company looking to improve the efficiency and quality of their PCB soldering and curing processes. This advanced oven / furnace provides highly repeatable temperature uniformity and precise temperature profiling, ensuring consistently high quality production every time. The added benefit of the 'on-line help' feature helps to reduce the time and cost associated with intensive training and manual labor, making VITRONICS SOLTEC XPM2 1030 an invaluable tool for any solder production line.

There are no reviews yet