Used VITRONICS SOLTEC XPM2 820 #9243057 for sale

URL successfully copied!

Tap to zoom

ID: 9243057

Vintage: 2006

Reflow oven

(8) Zones

Running hours: 15,240

Mesh belt conveyor, 20"

Nitrogen

Lead free ready

Heating and cooling: Top and bottom convection

Temperature for lead-free process: 350°C

Belt conveyor, 20"

Heavy duty frame

Individual cell inlet and exhaust

Flux flow control

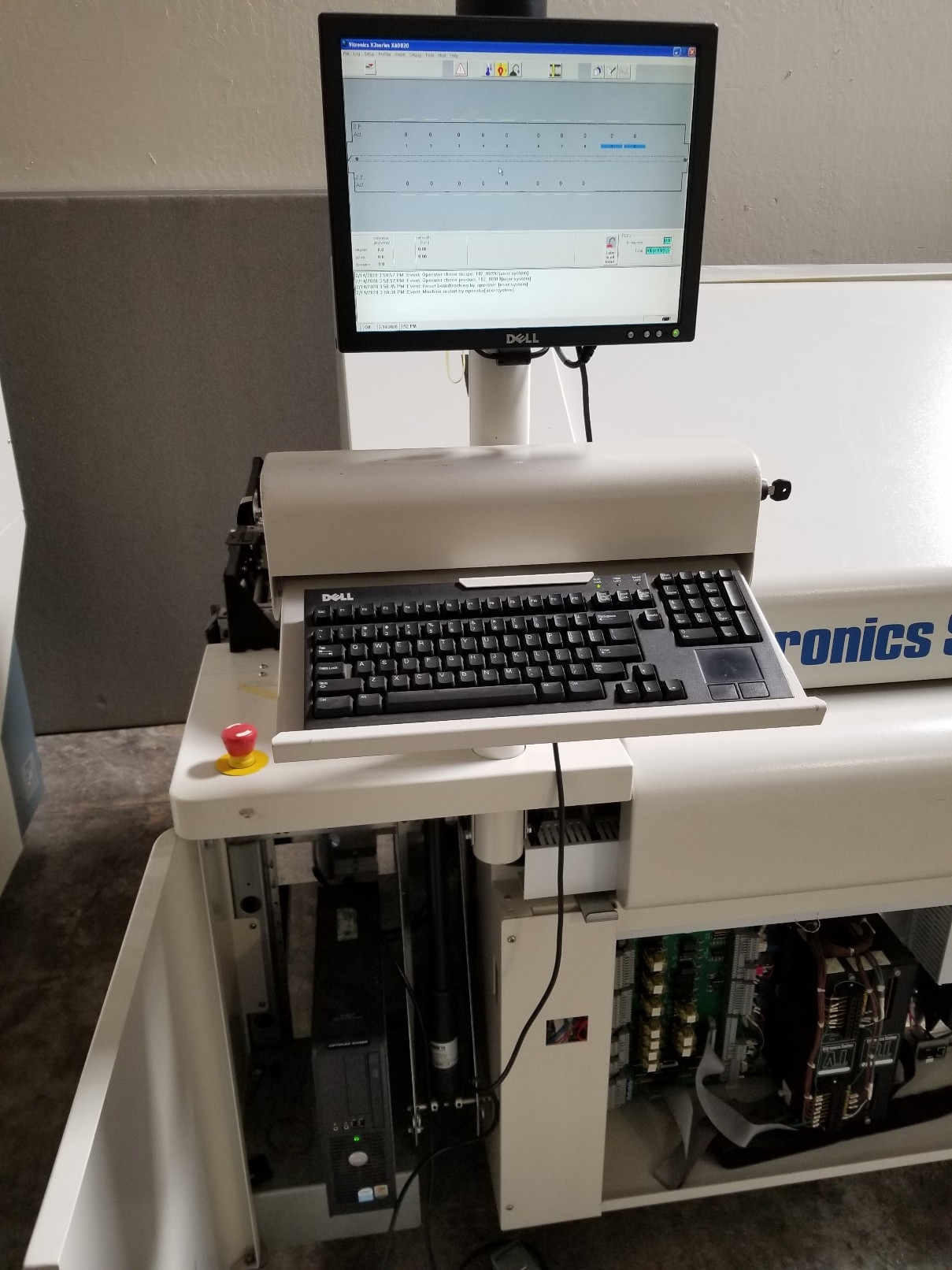

Operating system: Windows™

DELL Computer:

Flat panel display

Keyboard

Precision profiling

Powered hood lifts

Over temperature safety system

Belt conveyor, 24"

Combination edge rail and belt conveyor, 22"

Parking center support conveyor

Computer controller:

Rail width adjust

Edge rail lubrication

Polar cooling

Controlled cooling

Basic N2 package

True N2 / Air switching

Multiple atmosphere sampling port

OEM Integrated oxygen analyzer

O2 Doping

Cell blower speed control

Integrated exhaust stack filter

SMEMA Equipment interface

Power supply: 480 VAC, 3 Phase, 58 kVA

2006 vintage.

VITRONICS SOLTEC XPM2 820 is a reflow furnace developed for industrial production of printed circuit boards (PCBs). The furnace features a class-leading temperature uniformity for quick, efficient heating and cooling, and has multiple advanced features to improve production quality and throughput. The furnace has a compact, modular design, with a width of just 950mm and an internal chamber of 2600mm x 620mm. It is equipped with a powerful, 6kW stainless steel hot air heating equipment, and features an infra-red heating system and three-zone conveyor belt unit for rapid thermal transfer. At the heart of the symmetrically heated chamber is the high-performance IR heaters, allowing rapid, accurate heating and cooling. This ensures excellent temperature uniformity of ±2.0°C throughout the entire process. The ProFlow™ machine utilizes high-velocity forced air jets to maintain product temperature before, during, and after the process. VITRONICS SOLTEC XPM2-820 can operate with a wide range of temperature profiles, with minimum and maximum temperature range of 150-310°C. The high-tech microprocessor controller facilitates precise temperature control, and allows for setup and reading of the profile on the LCD display for easy monitoring. The user can input up to 7 segments, with each segment featuring timer delay, peak temperature, liquidus temperature, time-above-liquidus etc. The unit also features a mechanical snake chain conveyor tool, which ensures uniform speed of production for full size and mini pcbs. This helps avoid problems such as board sag or twisted corners that often occur in other conveyor systems. Additionally, recipe program settings can be inputted directly into the machine to help speed up production time. The PLC control asset further automates the operation with automatic start-up, shut-down, fault finder and error detector functions. Safety is another important aspect of the XPM2 800; it comes equipped with numerous features such as obstruction sensors, over-temperature protection, an O2 sensor, LEAD free protection coils, and an X-ray safety shutter model. All these features ensure a safe working environment in the production room. Overall, XPM 2-820 from VITRONICS SOLTEC is a reliable, efficient hot air re-flow furnace well-suited for mass production of a variety of printed circuit boards. It offers superior temperature uniformity, fast heating and cooling, and advanced safety features, making it a good investment for any production facility.

There are no reviews yet