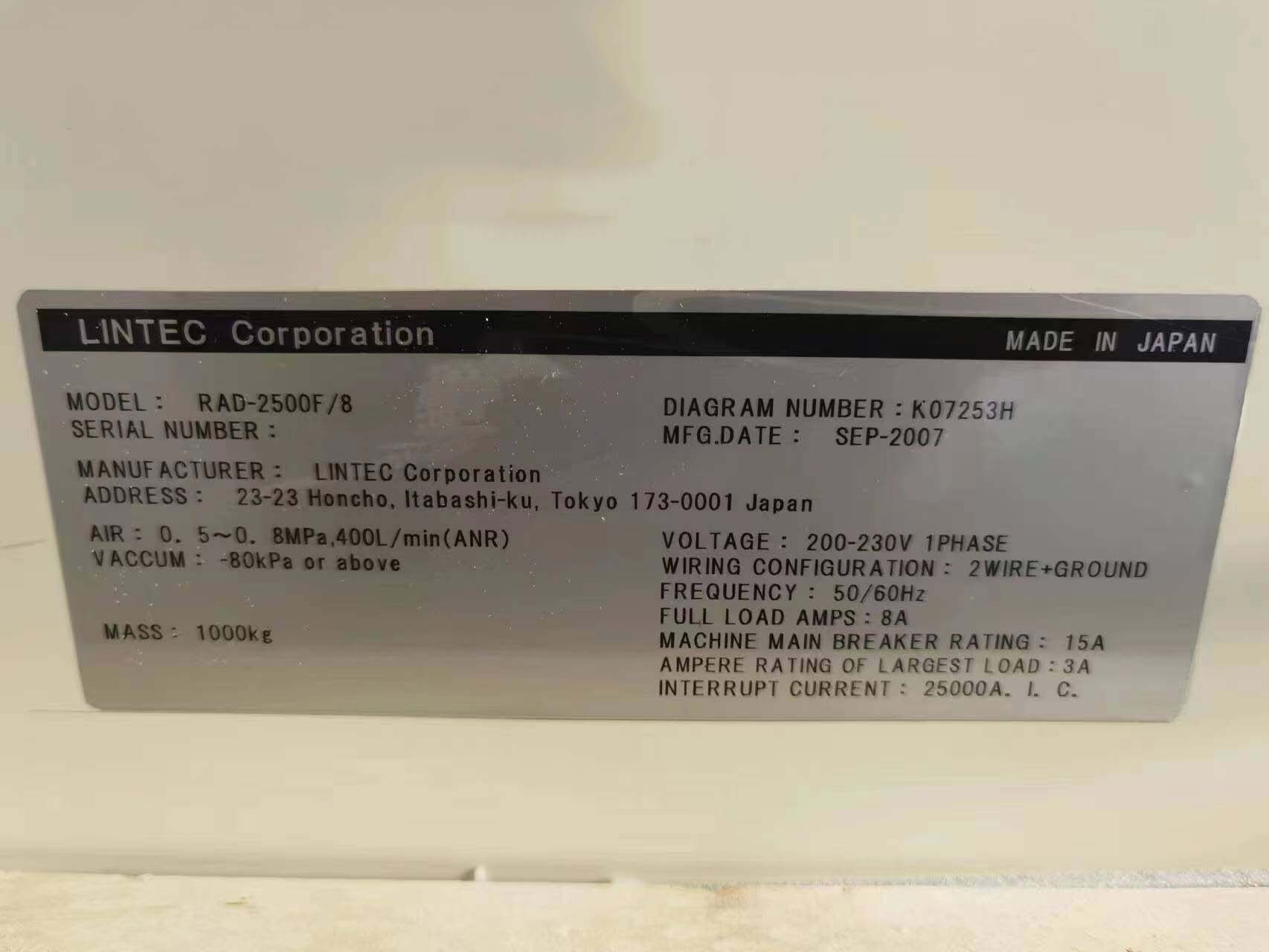

Used ADWILL / LINTEC RAD 2500 F/8 #293672297 for sale

URL successfully copied!

Tap to zoom

ID: 293672297

Wafer Size: 6"-8"

Vintage: 2007

Automatic wafer mounter, 6"-8"

Unit per hour: 100 wafers

Suitable tapes:

Pre-cut dicing tape: ADWILL D Series, G Series

Dicing die bonding tape: ADWILL LE Tape

Air pressure: 0.5-0.8 MPa

Air consumption: >400 L/min

Power consumption: 1.0 kW

Power supply: AC 200-230 V ±10%, 1 Phase, 50/60 Hz

2007 vintage.

ADWILL RAD 2500 F/8 is a fully automated packaging equipment designed to reliably shape and seal a variety of bags. It incorporates advanced technological advancements such as an intelligent electronic control unit, a machine vision system, and an I/O box to ensure high levels of accuracy and productivity. LINTEC RAD 2500 F/8 is a roll-fed pouch packaging unit which can create polyethylene, polypropylene, and laminated pouches of various sizes and shapes. Using a servo-motor drive, the machine can produce a variety of styles, including quad seal pouches, flat pouches, and fold-over pouches. The machine is easily adjustable to accommodate different product sizes, pouch sizes, and product flow rates. The intuitive touch screen makes switching configurations and programming operations easy. The machine features an intelligent electronic control unit, a machine vision tool and an I/O box as well as safety functions. The control unit provides user-friendly management, diagnostics, and troubleshooting of the asset. The machine vision model enables automatic pouch feeding via a high-resolution camera integrated into the infeed. Also, a barcode reader is available for product traceability and quality control. An I/O box is located between the controlling unit and the peripheral devices to ensure a good communication between the two sections. ADWILL / LINTEC RAD 2500 F/8 automatically shapes, seals, and trims the pouches. Depending on the setup, different techniques are utilized to obtain an optimal air and moisture tight seal. An advanced expansion device can be added to provide maximum control in forming the bag. High-quality sealing bars can be used to accommodate a wide range of pouch types, of any size. The striking feature of the equipment is the ability to perform two consecutive sealing cycles for additional sealing security and robustness. A nitrogen flushing system is also available in order to achieve a longer shelf life or avoid oxygen permeation. The pouch separating unit with the feeding machine integrated in the pouch conveyor is designed to reduce waste and product sticking, while oversized pouch detectors ensure that only properly formed packages are sent downstream. Overall, ADWILL RAD 2500 F/8 is an exceptionally durable and reliable packaging tool that provides companies with increased efficiency and speed. Offering easy installation, maintenance, and operation, the user-friendly service and well-built, reliable machinery make this asset an ideal choice for a variety of packaging needs.

There are no reviews yet