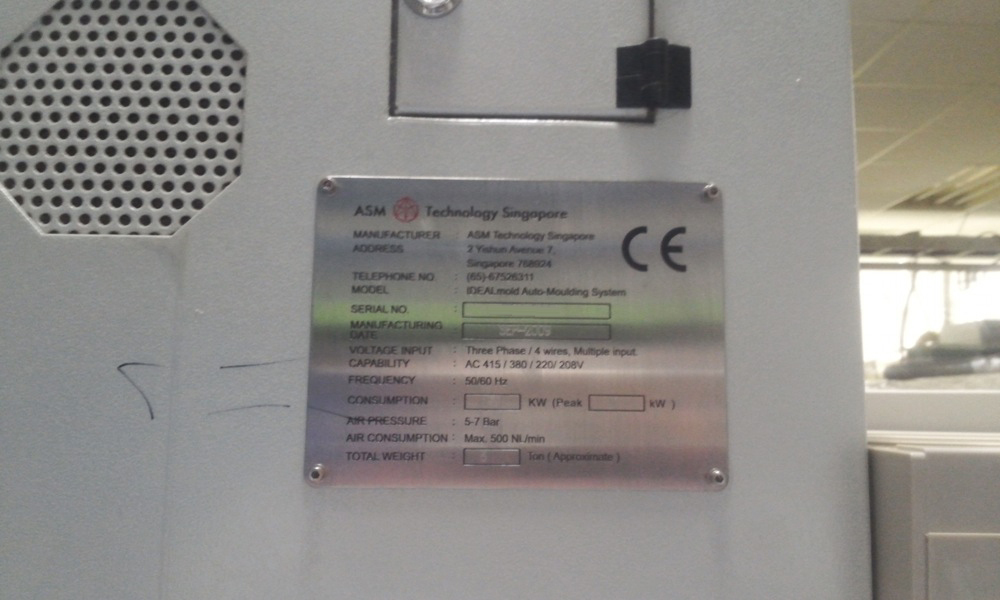

Used ASM IDEALmold #9040575 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9040575

Vintage: 2009

Idle molding system

PGS 80 Ton (2) Press system for POP & BOC - Excludes mold chase and PRP

Standard mold housing

Capability to handle 2 strips per mold chase based on package

Individual substrate compensation for 2 substrates within mold chase

Vacuum mold

Dry lub coating

(1) vacuum pump per press

Set of POP Mold chase - Top, bottom and middle plate

Motorized wedge housing for PCB thickness compensation

Special mold housing for Towa mold chase (BOC)

Product related parts (PRP) conversion kit for POP

PRP conversion kit designed for Towa mold chase

Automatic digital pellet weight system

IDEALtrolley

Standard spare parts

2009 vintage.

ASM IDEALmold is a modern packaging equipment designed to optimize the speed and efficiency of injection molding processes. The system is powered by ASM proprietary Intelligent Molder Operating Unit (IMOS) software, which utilizes data-driven digital moulding technology to create and monitor perfect repeatable plastic parts in injection moulding processes. ASM IDEAL MOLD provides users with a complete suite of features designed to improve accuracy, reduce cycle time, and increase quality of parts in any injection molding project. At the heart of IDEALmold machine lies the IMOS software, which takes data from digital 3D models and uses it to create perfect, repeatable tooling profiles for injection moulding. It also helps to accurately control the moulding process with real-time control of temperature, pressure, and injection speeds. Thanks to the hot Runner systems compatible with IDEAL MOLD, users can also quickly load moulds for injection on the same machine. The software collects data throughout the moulding process and, by analyzing this data, enables users to measure and optimize the injection process. This data includes insights into individual parts, optimal cycle times, and even production simulation that can be used to minimize material wastage. Additionally, ASM IDEALmold includes advanced process control features for real-time process monitoring and automated alerts. ASM IDEAL MOLD tool also provides users with powerful injection simulation capabilities that allow them to adjust settings, simulate part design, and optimize process parameters. The software also allows users to create repeatable and traceable production plans with the help of real-time data selection and plastic injection moulding simulation. In addition to the impressive software capabilities, IDEALmold asset includes several hardware tools that make injection moulding easier and smarter. These include a control box and production module that allow users to control injection speed, cycle time, and temperatures. The model also features an insulated mould box, which helps speed up the moulding process and ensure accurate parts with precision cooling. Thanks to its combination of advanced software and hardware components, IDEAL MOLD is a highly efficient and effective packaging equipment for injection moulding projects. By facilitating real-time control, simulation, and optimization of the injection process, ASM IDEALmold helps to ensure accuracy, reduce cycle time, and maximize the quality of injection moulded parts.

There are no reviews yet