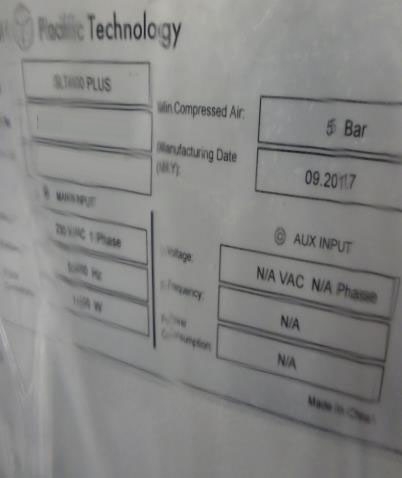

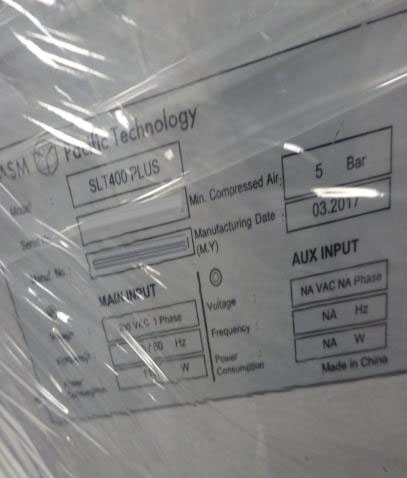

Used ASM SLT 400+ #9280865 for sale

URL successfully copied!

Tap to zoom

ASM SLT 400+ is a high-speed, automatic, robotic packaging equipment designed to meet the most exacting standards of operation in the food, pharmaceutical, and consumer-goods production industries. This system offers maximum accuracy and precision, with minimum downtime, to ensure the highest possible quality and reliability of packaging operations. Thanks to its compact size and advanced robotic technology, SLT 400+ can handle a wide array of container formats, ranging from the standard carton, pouch, and bottle formats to the more specialized clamshell, tray, cup, and jug formats. The unit utilizes top and bottom gripper arms to pick and place product to one of two right-angle orientation stations, allowing the user to select either a drop or non-drop orientation when packaging. This ensures that the product is consistently and accurately positioned in the container, for maximum efficiency. ASM SLT 400+ is capable of housing up to eight different types of product simultaneously. By using a modular design, the machine can be configured to suit each client's individual needs. With its ability to integrate with external equipment, such as high-speed feeding systems, SLT 400+ allows users to maximize the efficiency of their production line, as well as reduce downtime and associated costs. The tool is also equipped with a Human Machine Interface (HMI), which allows operators to adjust settings, monitor production, and update programs quickly and easily. The HMI comes equipped with an interactive touch screen and a range of diagnostics tools to help ensure the asset is always performing optimally. ASM SLT 400+ is a highly reliable, automated packaging model that provides users with high-precision, high speed, and low-maintenance, for maximum cost-efficiency. Thanks to its modular, customizable design, the equipment is capable of accommodating a wide range of container formats, making it the ideal solution for high volume production operations.

There are no reviews yet