Used CLARION CD 65L #9230470 for sale

URL successfully copied!

Tap to zoom

ID: 9230470

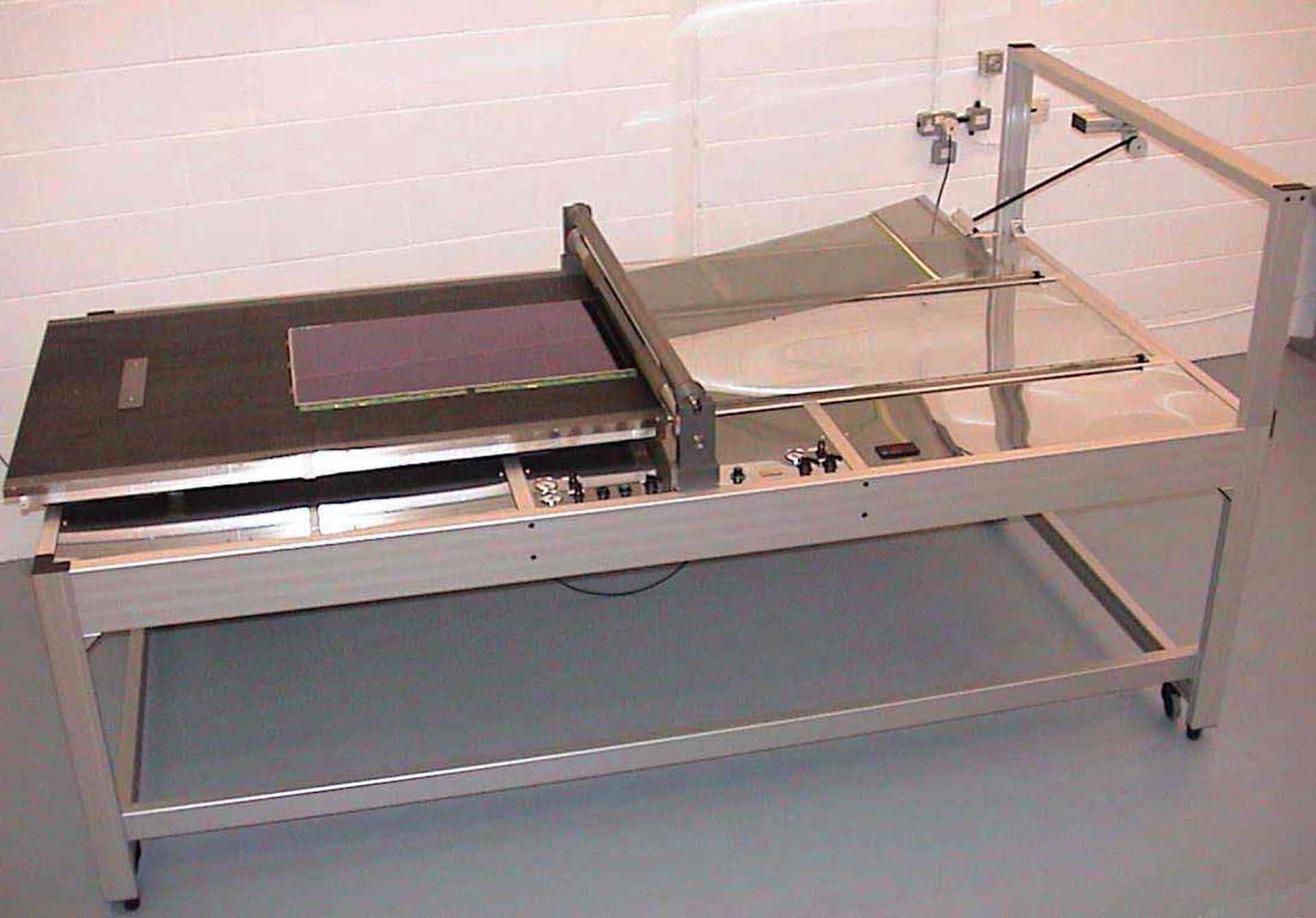

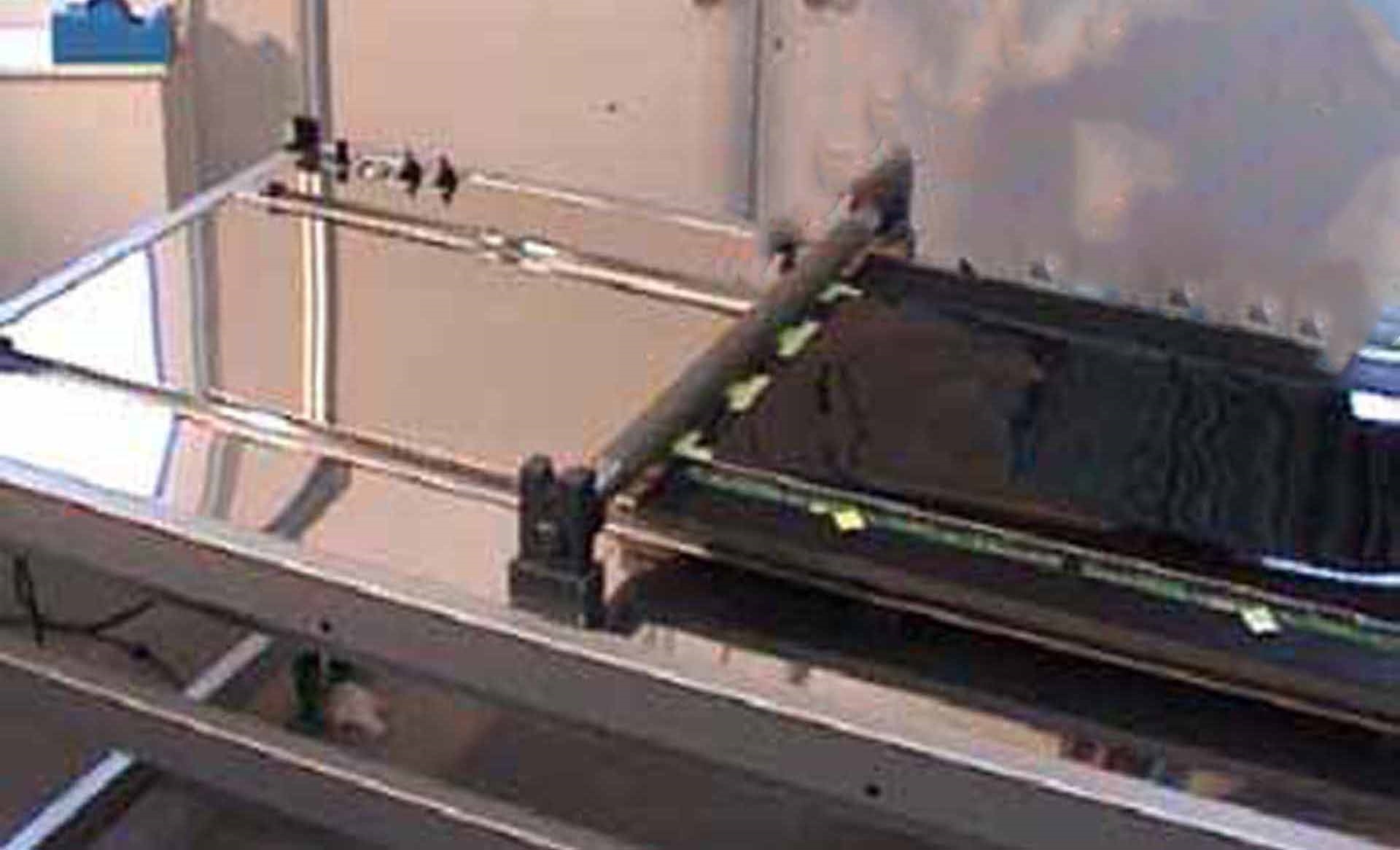

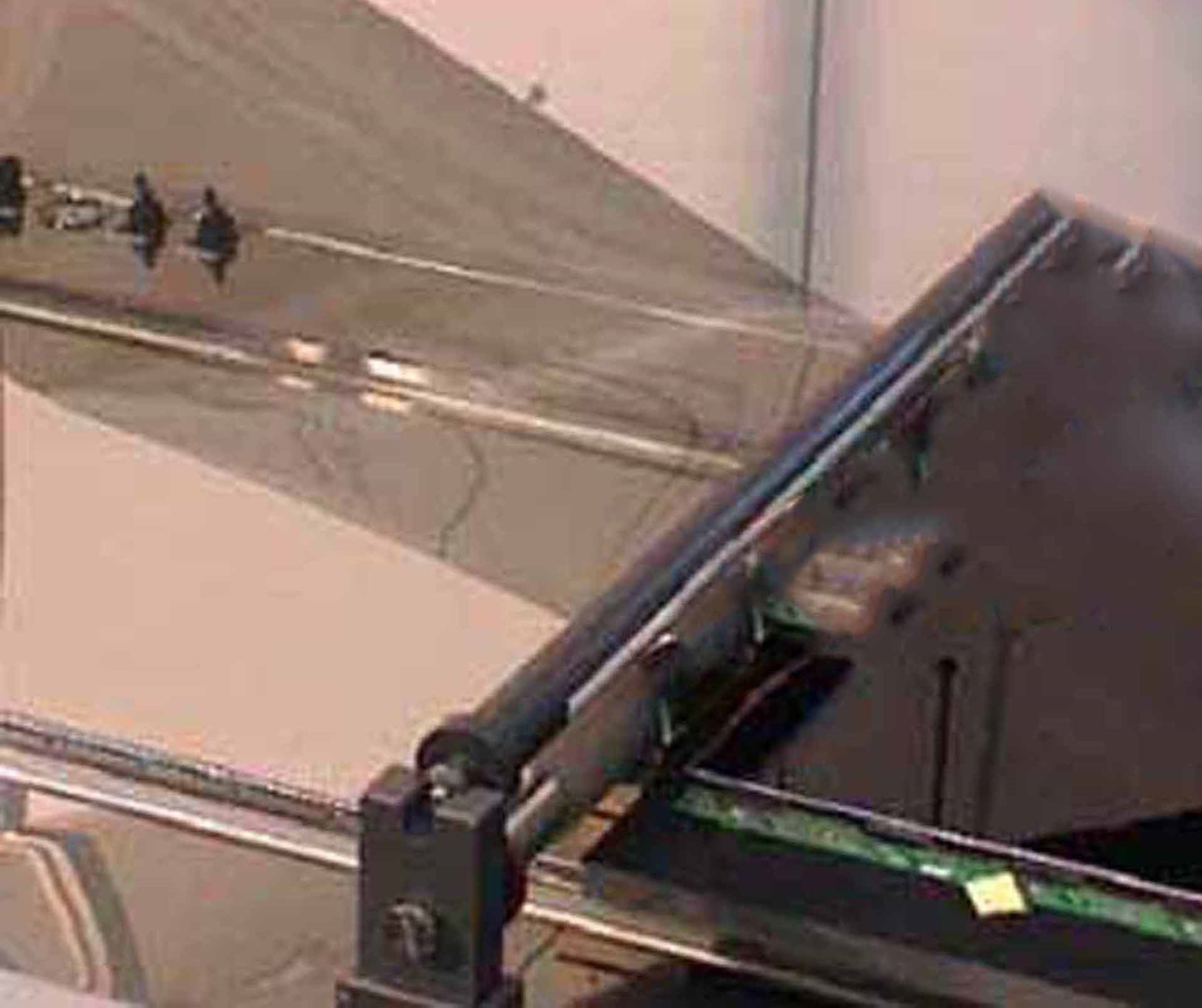

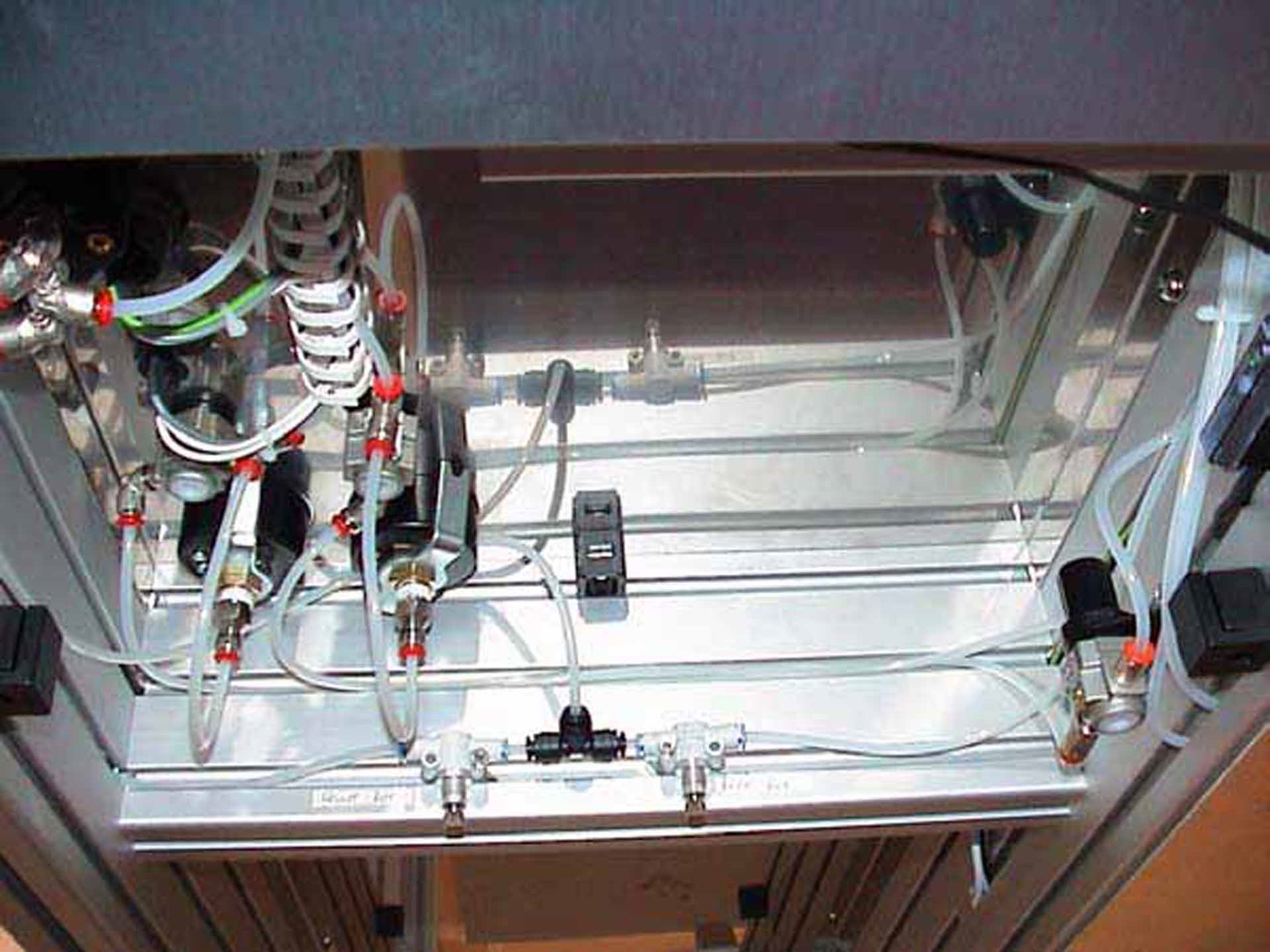

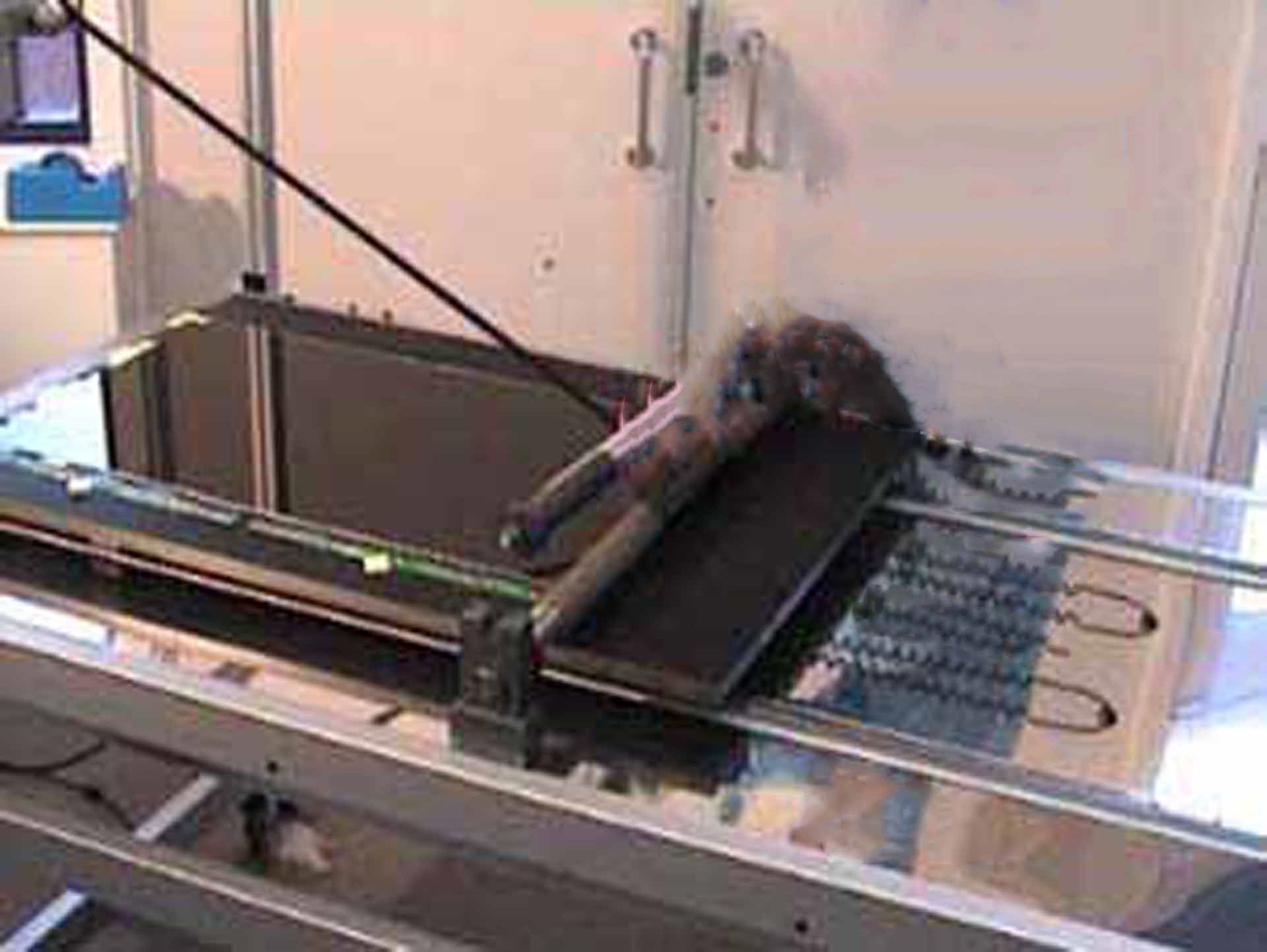

Laminating system

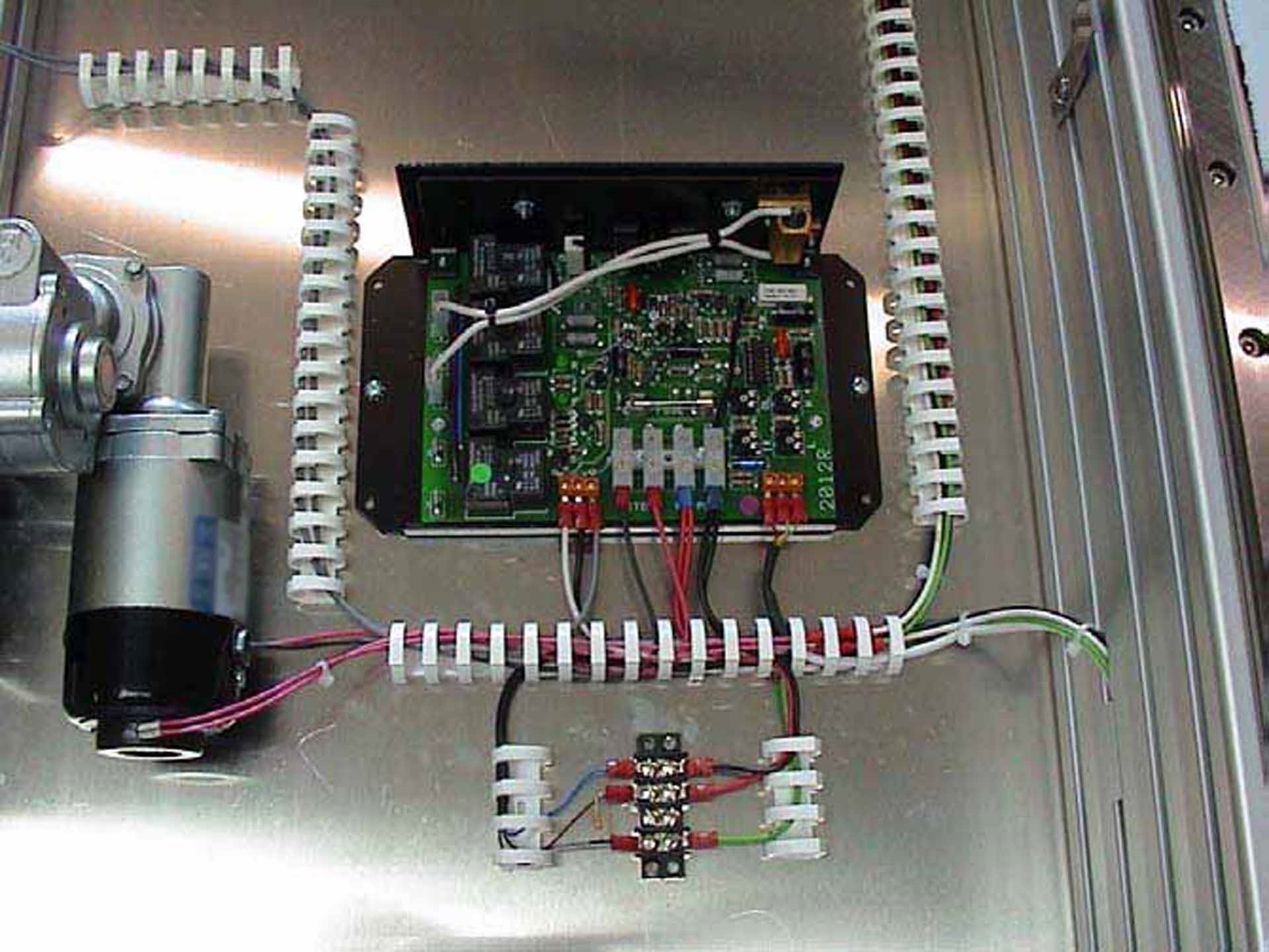

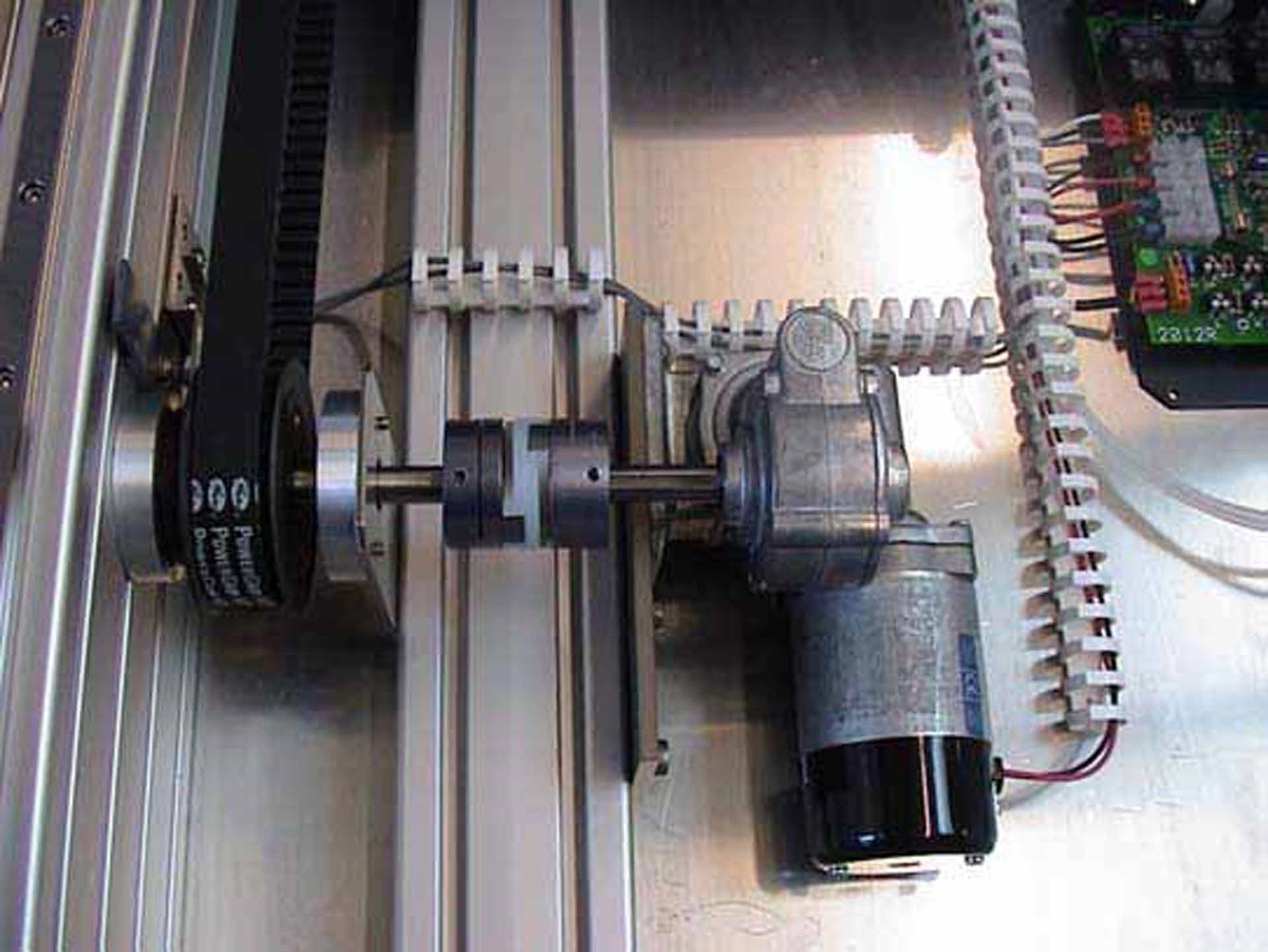

DC Electric motor

Pneumatic cylinder

LCD Panel

ESD Connection

Tensioner control

Safety consideration

Fault diagnosis

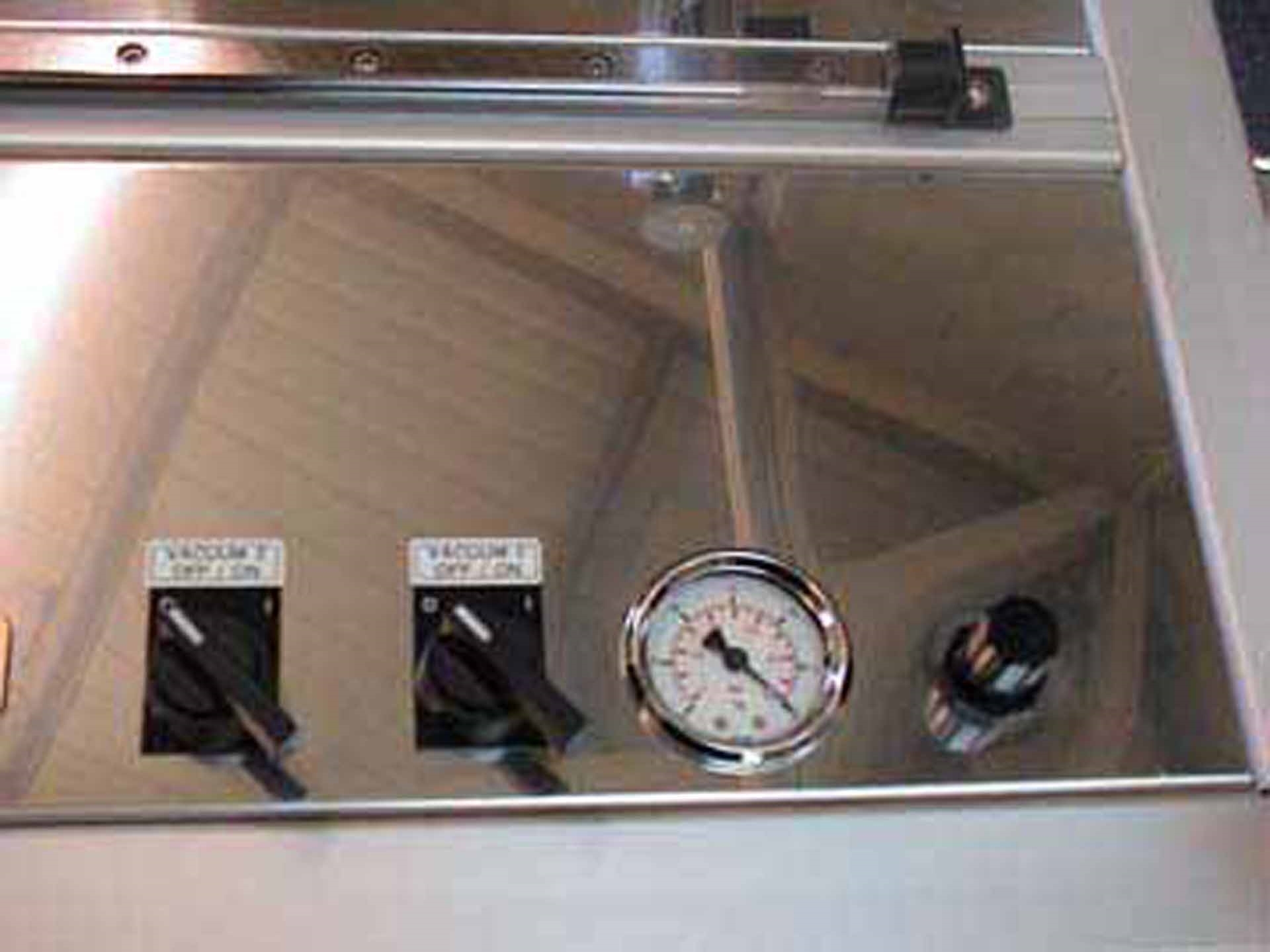

Right side controls:

Table speed adjustment

Vacuum pressure gauge

Vacuum pressure regulator

Vacuum on / Off switch

Left side controls:

Laminating roller pressure

Roller lift pressure

Drive table backward

Drive table forward

Raise / Lower roller

End panel controls:

Power supply cord socket

Power on / Off

Air supply: 6 mm

Pneumatic supply requirement:

Regulated

Filtered dry compressed air at 80 PSI min

Power requirement: 110 / 115 V or 220 / 240 V, AC - 5 AMP min

Qty / Part no / Description

(1) / CD 0612 / Laminating roller with drive wheel

(1) / 3M 1350 25 mm / Yellow polyester tape

(1) / 5168 / White poly backing peel tape

(2) / CD 0607 / Roller drive o-rings

(1) / 245-9599 / Neoprene rubber mat

(1) / PM10C MBM / DC Drive motor 24 V

(1) / 748-617 / Tensioner clutch

(1) / 2012 RP / Motor control card

(1) / PS 24V 6A / 24V 6A Power supply

(1) / 338-4828 / Drive belt

(1) / 748-190 / Motor coupling torque disc

(1) / 359-8500 / Table jack drive belt

(1) / 11914 / Roller up / Down switch valve

(2) / 170919 / Roller up / Down cylinders

(2) / MWC 7010011200 / Pneumatic spool valves

(2) / 6817 / Vacuum on / Off switch valves

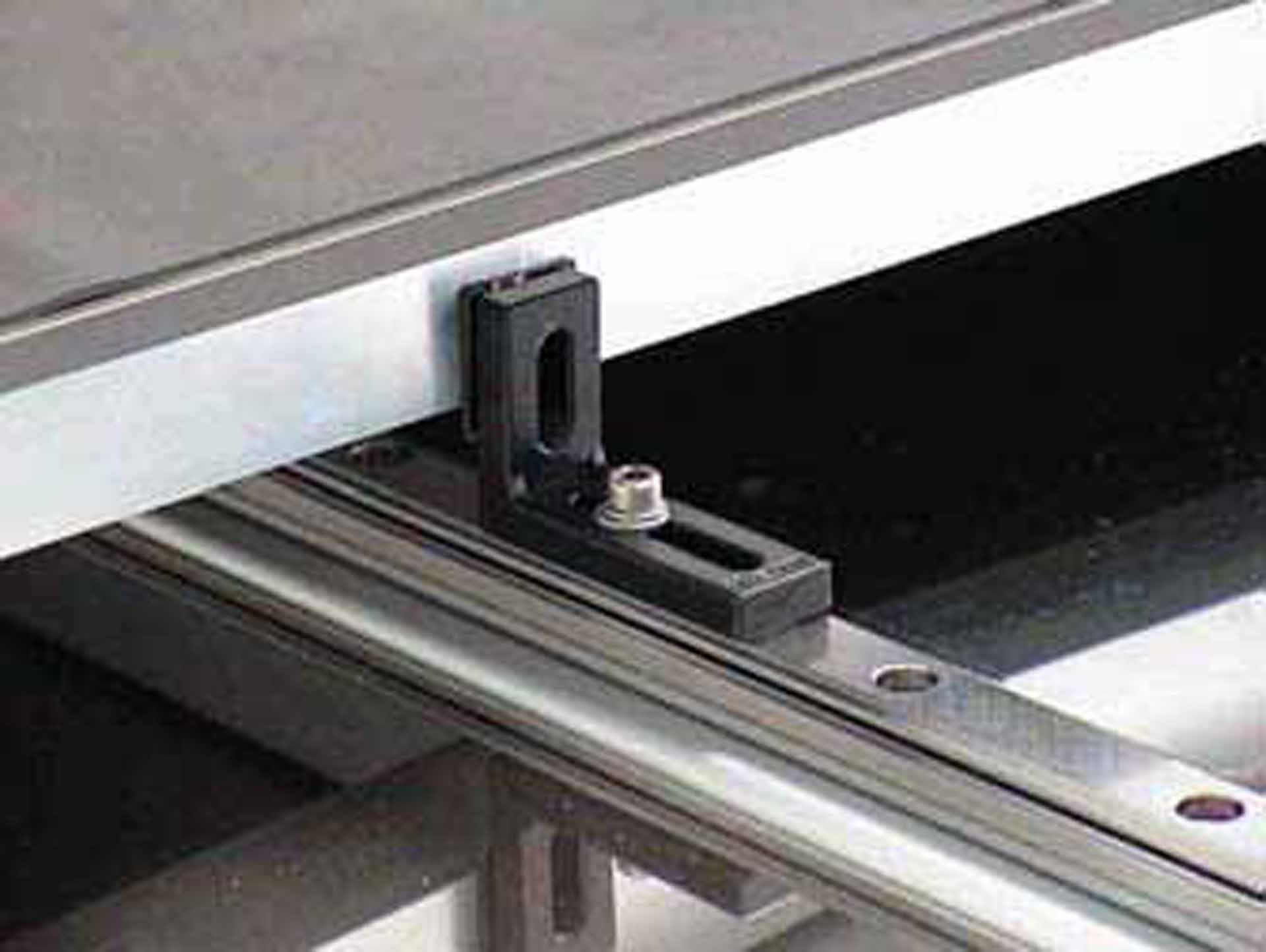

(1) / 159-4433 / Table travel limit switch

(1) / PS-49C / Optical sensor head unit

(1) / PS-T1 / Optical sensor amplifier

(1) / 665-994 / Green push switch

(1) / 320-821 / Black push switch

(1) / 193552 / Vacuum generator

(1) / 173-215 / Speed control potentiometer

(4) / LAS 20 ALZ / Linear rail carriages

(3) / 186-0746 / Air pressure regulators

(2) / 245-1983 / Vacuum curly pipes

(2) / 42-8926 / Pressure gauges

(1) / WG50-030-01BPMV / Vacuum gauge.

CLARION CD 65L is a highly efficient and robust packing equipment designed for medium-volume applications. The system contains a number of components including a top line feeder, a pusher, a feeding track, product divider, product dispenser, packing technology unit and glue applicator. The top line feeder is used for conveying the products securely along a continuous feeding track towards the packing zone; this conveyor may even be extended to reach up to 60 m in overall length. The pusher is the core component of the unit as it serves to move, orient and position products onto stationary supports of the packing technology unit, rapidly and continuously. The product divider ensures that the goods arrive in a perfectly aligned position with no overhangs over the sides, as the products are directly sent from the feeding track to the product dispenser. The product dispenser add the required number of products for each given packing unit and the packing technology unit seals specific unit types and packs them into a flat format. The glue applicator is used to affix the self-adhesive labels or package the goods into carton boxes. The user-friendly control machine is operated with a touch panel display. The programming of the tool is carried out via a simple menu structure which provides overviews of the entire line, the most commonly used settings and statistical data. This asset also provides a detailed follow-up of the process from feeding to packaging. CD 65L offers reliable operation and high-speed performance. The model maintains a high degree of accuracy while maintaining product quality and preventing damage. The equipment features an integrated weighing system and an automatic measuring unit which allows adjustments of settings to compensate for changes in material composition, providing near-perfect performance. With a wide range of packaging features available, this machine can be used for a variety of packing applications. Overall, CLARION CD 65L is a reliable and cost-effective packing tool designed for medium-volume applications. Its efficient design, user-friendly controls and wide range of packaging features make it a great choice for ensuring product quality and efficient operation.

There are no reviews yet