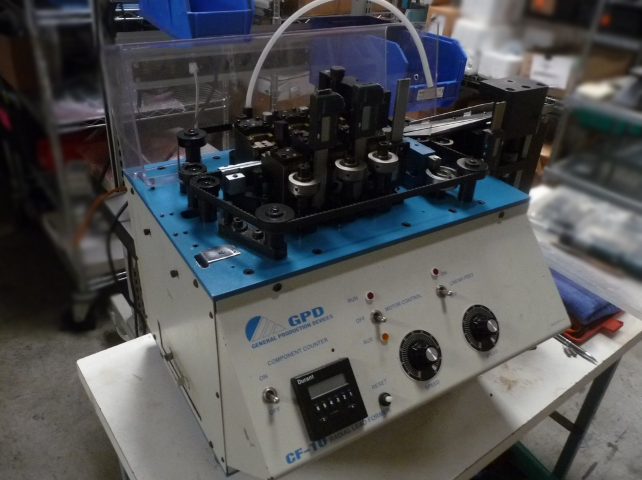

Used GPD CF-10 #9101926 for sale

URL successfully copied!

Tap to zoom

ID: 9101926

Radial lead former

Capable of forming loose radial components at rates up to 6,000 parts per hour with a variable speed motor

Feed components by hand or with tubes (TO-220s)

Reduce setup time with quick change tooling and repeatable station settings

Forms bulk radial-leaded components to numerous form styles

Component Forms:

Reducing Form

Reducing Form with Lock In Stand-off

Spread Form

Spread Form with Lock In Stand-off

Lock In Stand-off Form

90 Degree Angle Bend

Flush Mount Lock In Form

Stand-off Lock In Form

Inline Lock In

Stand-off Form

Middle Lead Offset Form

Middle Lead Offset with 3 Lead Lock In Form

Middle Lead Offset with Lock In Form

TO-220 Lock In Stand-off

TO-220 Offset toward Heatsink

TO-220 Lock In Offset away from Heatsink

TO-220 Offset away from Heatsink

TO-220 90 Degree Middle Lead Stagger

TO-220 90 Degree toward Heatsink

TO-220 90 Degree away from Heatsink

TO-220 Inline

TO-220 Middle Lead toward Heatsink

TO-220 Middle Lead away from Heatsink

5 Lead TO-220 90 Degree Stagger

5 Lead TO-220 Offset Pattern away from Heatsink

5 Lead TO-220 Offset Centered Pattern.

GPD CF-10 is a fully automated packaging equipment designed to give end users maximum flexibility and reliability. CF-10 system handles product loading, forming, filling, sealing, labeling, and offloading to create bags, pouches, cartons, and even shrink wrap. The unit is designed to accommodate a wide variety of product types and configurations. The form, fill and seal machine of GPD CF-10 consists of several production sections which are designed to run simultaneously. The product is first transported to the first section, where a careful pre-forming process takes place. Different gas, vacuum and mechanical pre-forming devices are used to shape the product to the specific requirements of the packaging. The shaped product is then transported to the next section, where the filling and sealing process takes place. This is done by a controlled and regulated mixture of air, vacuum, and pressure to fill each package with the specified product. The product is then passed to an integrated sealing section, where a wide variety of sealing options are available. Compression heat sealing, ultrasonic bag sealing, and line banding are all available to get the desired product shape and seal. Finally, CF-10 features an integrated labeling tool that can apply labels to the top and bottom of the sealed package. Labels can be selected for use on the basis of their specific size, shape, and configuration. GPD CF-10 is a very efficient and reliable packaging asset. The use of this model decreases the manual labor and increases production speed and quality. In addition, its integrated safety systems, like its shock detection and overload protection, provide an extra layer of security, giving users peace of mind when operating the equipment.

There are no reviews yet