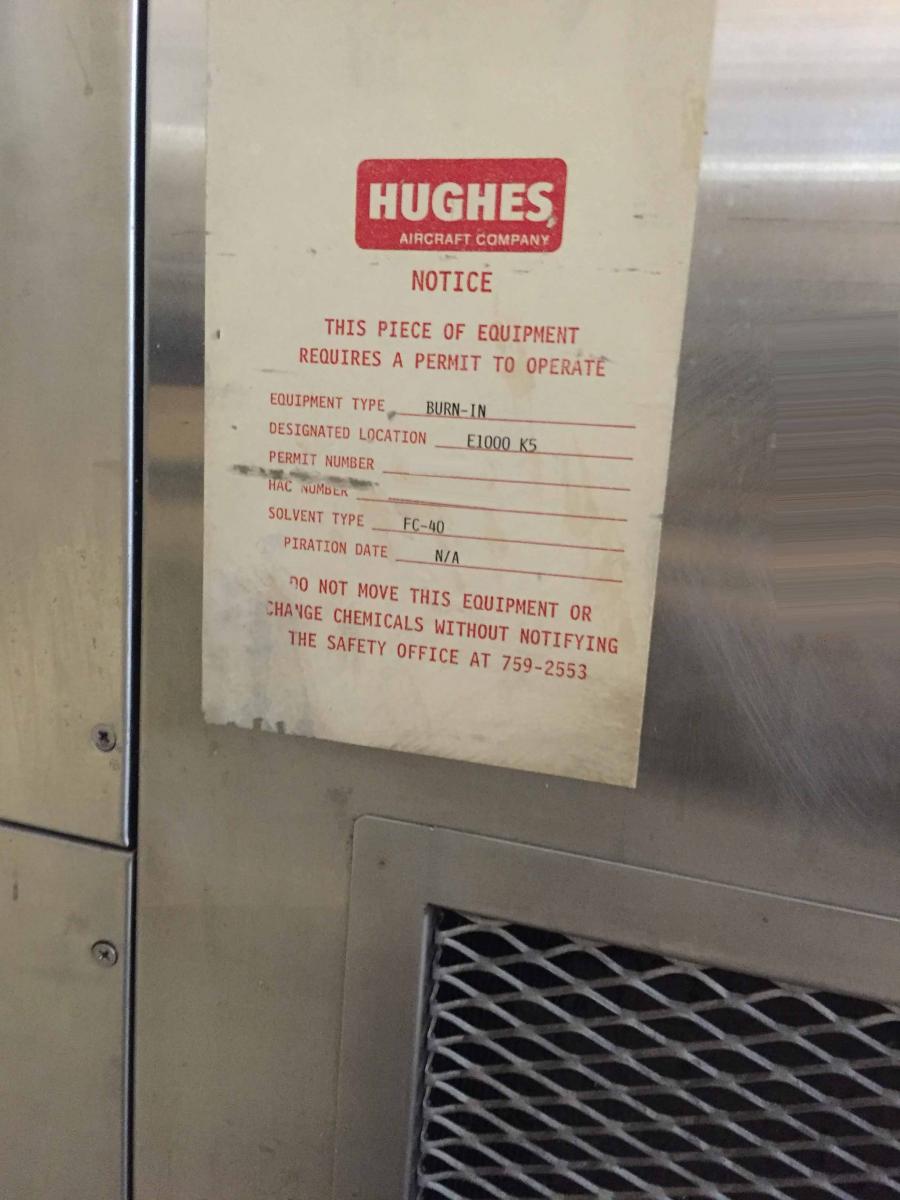

Used HUGHES Burn-In #9148169 for sale

URL successfully copied!

Tap to zoom

HUGHES Burn-In is an automated package Burn-In equipment designed to test the quality and reliability of various electronic components. The system consists of a network of specialized modules that interact to run HUGHES Burn-In process. Each module contains a controller, characterizing/screening software, a programmable automation controller (PAC), and a series of test fixtures. The PAC is responsible for communicating with each of the test fixtures while the characterization /screening software is used to control the operation of the unit. The controller then records Burn-In results and informs the operator when the process is complete. HUGHES Burn-In machine utilizes a computer-controlled environment to heat up and cool down the input packages in order to perform evaluation tests. The tool also uses a vacuum chamber to reduce the temperature time required to tests components. Once the chamber reaches the designated temperature set by the operator, all the components inside the chamber are put through a pre-defined sequence of tests. During each test, measurements are taken of the devices' performance. Once all the tests are completed, the integrated device can be marked as having passed or failed, depending on the overall performance of the asset. Burn-In model also provides a variety of reporting capabilities. This includes HUGHES Burn-In test overviews, real-time test results, thermal test data, device testing results, as well as detailed Burn-In statistics. These reports can be configured using a variety of different data formats, such as PDF, Text, CSV, XML, etc. This enables the user to customize the reports in order to make more informed decisions regarding their device testing. HUGHES Burn-In equipment also integrates with existing manufacturing processes, allowing for reduced downtime and improved efficiency. It also ensures that devices are tested to the highest standards, thus allowing a company to produce the highest quality products at the lowest possible cost. The system also includes an intuitive user interface which serves as an additional tool to assist in Burn-In process. Overall, HUGHES Burn-In unit provides an efficient and cost-effective method for testing a variety of electronic components, as well as an impressive array of reporting capabilities and integration options. It provides the user with detailed information regarding the overall performance of tested devices, while also ensuring that they are being tested to the highest standards.

There are no reviews yet