Used ISMECA TMBZ SP #139893 for sale

URL successfully copied!

Tap to zoom

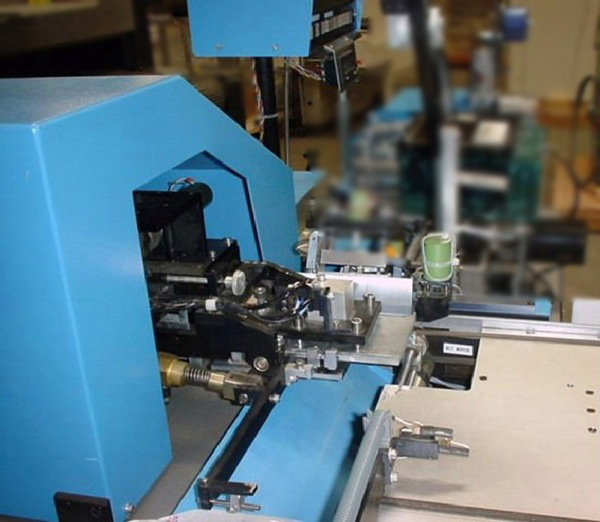

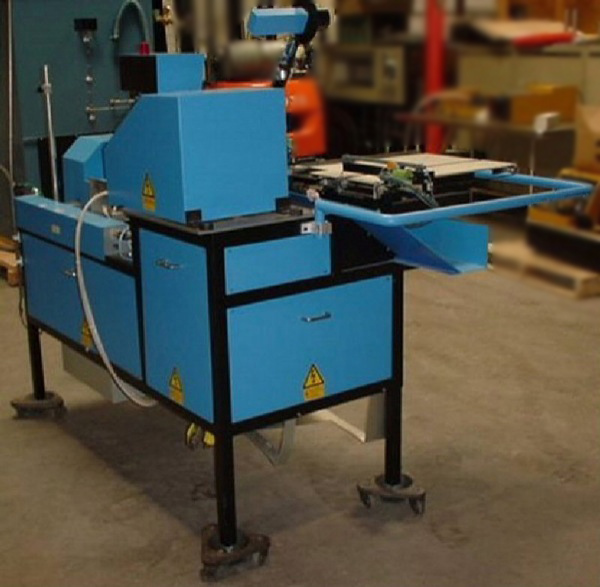

ISMECA TMBZ SP is a cutting-edge packaging equipment designed to integrate flexible material handling, high level of protection and reliable filling. It is perfect for pharmaceutical, nutraceutical and cosmetic industries needing to package products with precise control and accuracy. The system is primarily made up of several key components: a precise bagging unit, filling and sealing machines, vision inspection systems, diverter systems and other supporting elements. The precise bagging machine allows for the precise positioning, batching and weighing of pre-conditioned materials such as tablets, capsules and other packed products. The highly advanced filler and sealers then fill and seal the packages and ensure that each product meets precise standards. Additionally, to ensure quality, the vision inspection tool is capable of detecting any defects in the product or packaging and sorting out those that do not meet requirements. ISMECA TMBZ.SP also includes a diverter asset, a set of conveyors that are used to transport empty and full packages of different shapes throughout the assembly line. This helps ensure that production runs smoothly and efficiently at all times. Furthermore, in order to ensure that all processes remain safe, the model also includes fail-safe and secure sensors and actuators to detect any abnormal operation and alert the operator. The equipment also features a host of other features that allow for greater flexibility and control, such as virtual programming, automatic data collection, bar-code readers and automatic devices for tracking. This ensures that the operator is aware of the exact product specifications and production capabilities of the system before production even begins. Overall, TMBZ-SP is ideal for companies that need to package products with precise control and accuracy. It incorporates advanced technology, such as vision inspection systems and secure sensors, as well as providing flexibility and control through virtual programming and automatic devices. In short, it offers a high level of performance and flexibility that can be tailored to meet any unique packaging needs.

There are no reviews yet