Used JSW J-385E II #9111507 for sale

URL successfully copied!

Tap to zoom

ID: 9111507

Vintage: 1998

Molding machine

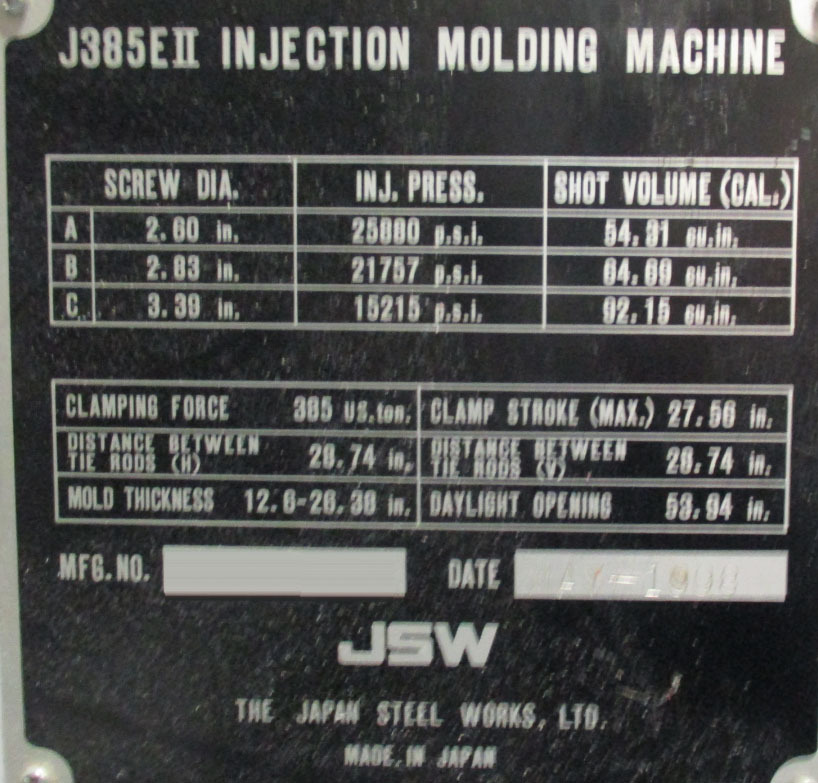

Tonnage: 385

Screw size: 66 mm

Max. injection pressure: 25886 psi

Injection capacity: 890 cm^3 (28.6 oz)

Screw stroke: 190 mm

Max. ejector stroke: 150 mm

Distance between tie bars: 730 mm x 730 mm

Platen size: 1035 mm x 1035 mm

Daylight: Up to 1370 mm

Stroke clamp: Max. 700 mm

Controller: JSW

Hydraulic knock-off: Yes

(1) Air blowers

Core pulls: None

YUSHIN Robot

Power: 480 V

Material ran: Nylon

Shifts ran: 3

Types of products molded: Cable ties

Typical cycle times: 10 - 20 sec

Hours / Cycles: 2,323,863 Cycles

Currently installed

1998 vintage.

JSW J-385E II reel packaging equipment provides high-end, reliable performance for a variety of applications. It is an efficient and cost-effective solution for reel-unwinding, wrapping and stacking operations. The system is ideal for lightweight materials such as films, paper, non-woven materials, aluminum foil, and other lightweight materials. The J-385E is equipped with an array of features to ensure efficient performance and reliable operation. The unit is powered by an energy-efficient control machine, which allows for smooth operation and precise control. The drive tool is a servo motor that provides an acceleration and deceleration ramp for accuracy and smoothness, as well as superior torque. The motor also has the ability to ramp up and down for accurate performance in a variety of applications. The PLC controller is a powerful and user-friendly device that allows for programmable control. The controller allows for a vast array of parameters, including control of start, stop, speed, and direction of the motor. Variables such as motor speed and material length are adjustable to meet the needs of the specific packaging application. The automatic loading and unloading asset can be programmed to allow for faster, more efficient packaging processes. A dual-bay tension model ensures that material is securely wrapped and tightly held, providing a reliable packaging solution. The equipment also has an automatic sheeting device that automatically sheet material, resulting in a neat and orderly package presentation. For quality assurance, JSW J385EII has a built-in reject detector and a video inspection system. The reject detector eliminates defects from material rolls and the video inspection unit allows for visual inspection of the material prior to packaging. It is also integrated with an online remote operation and diagnostic machine for real-time monitoring of the tool performance and operation. J-385E II is compatible with a variety of automation and material handling systems, making it an ideal solution for difficult packaging applications. Additionally, this asset provides excellent value for its cost, making it an ideal choice for many businesses.

There are no reviews yet