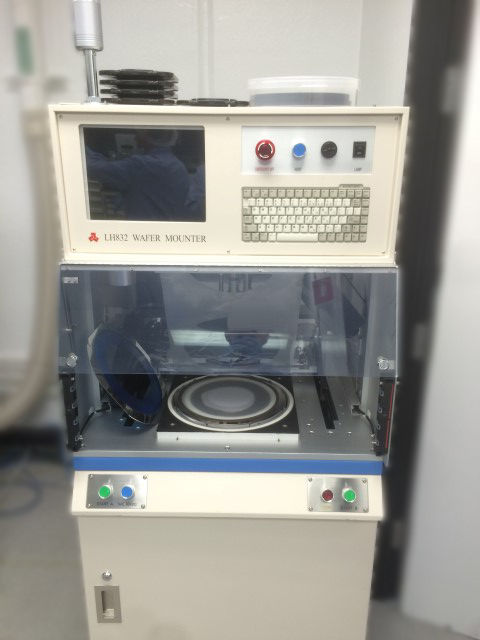

Used LONGHILL LH 832 #9174748 for sale

URL successfully copied!

Tap to zoom

ID: 9174748

Wafer Size: 4"-8"

Vintage: 2000

Wafer mounter, 4"-8"

Wafer thickness: 6" (125 micron) min

DISCO / K&S 305 Frames (Standard)

Tape width:

265 mm, 4"- 6"

345 mm, 8"

Tape length: 100 m

Tape thickness: 0.05 - 0.15 mm (2-6 Mil)

Tape tension: 1.5% to 4.5% Stretching

Wafer table: Non-contact type with vacuum system

Wafer table temperature: Up to 60°C

Wafer cycle time:

30 Seconds for 6"

40 Seconds for 8"

Throughput: 60-80 Wafers/hr

Compressed air: 60 PSI (Dry air)

Air bubbles free mounting

Minimal contact with wafer

Vacuum mount (No roller)

Wafer capability: 3"-8"

UV Tape capability

High accuracy in X, Y and theta rotation

Power supply: AC 220 V, 50/60 Hz, 10 A

2000 vintage.

LONGHILL LH 832 is an advanced packaging equipment designed to maximize the efficiency of industrial processes. This packaging solution is suitable for a wide variety of applications and is equipped with several advanced features for simplified operation. This advanced packaging system is equipped with a servo motor-generator to ensure reliable and accurate package delivery with faster speed. The integrated material handling capabilities allow for quick loading and unloading of cartons, as well as easy tracking of materials. It also has a compact design that can fit into existing production lines and requires less additional space. The unit is also desirable for its low-maintenance design, which allows for reliable operation in various environments. The advanced features of LONGHILL LH832 include two speed levels - low and high - to accommodate various types of materials. The integrated belt conveyor allows for adjustable speeds and consistent package movement. The machine also includes a computer-controlled solenoid valve to provide exact delivery control. The vacuum chamber can be configured to adjust to various package sizes, allowing for a greater degree of flexibility. Additionally, the tool has an integrated temperature control asset to enable efficient cooling of packages as needed. LH 832 also includes several safety features, including anti-shock protection which helps to ensure package integrity and consistency. The model also is equipped with an automatic underrun protection, which cuts power whenever the motor is overloaded, to ensure safe operation. Finally, the integrated dust suppression equipment helps to minimize and limit dust particles from entering the packaging environment, helping to further improve operator health and safety. LH832 offers an efficient and reliable packaging system for industrial applications. Its cutting-edge features make it easy to operate and maintain, making it an ideal solution for businesses looking for improved packaging line efficiency. Its flexible design and safety features ensure safe operation in all types of environments, making it a great choice for any industrial process.

There are no reviews yet