Used MEYER BURGER / SWISS SOLAR SYSTEMS / 3S NG 4222 XLCP #9194851 for sale

URL successfully copied!

Tap to zoom

ID: 9194851

Laminator

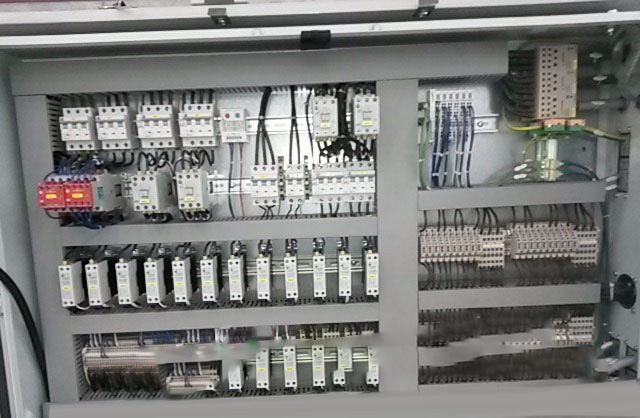

Control system:

Type: PLC, Beckhoff

Monitor: Touchscreen, 15"

Operating system: Beckhoff real-time kernel / Windows XP

Colors:

Machine frame: RAL7035

Red stripes: RAL3020

Housing: RAL7035

Switch cabinet: RAL7035

LEYBOLD Vacuum pump: RAL7035

Hyfra cooling unit: RAL7035

Noise level:

Laminator: < 74 dBA

Vacuum pump SP630: < 74 dBA

Vacuum pump SP630F: < 74 dBA

Vacuum pump SP630 / Ruta WAU 2001: < 79 dBA

Vacuum pump SP630F / Ruta WAU 2001: < 79 dBA

Vacuum pump SP630F / Ruta WAU 2001 / Noise insulation: < 59 dBA

Standard chiller (CWK90): < 73 dBA

Chiller XL (SVK220): < 76 dBA

Average power with vacuum pump, chiller and 4 modules: 70.2

Stand-by power: 20

Peak power: 94

Consumption (l/cycle): 40

Process exhaust air:

Volume (m3/cycle): 2.8

Connection of vacuum pump air exhaust: DN1001S0-K

Water connection for the cooling unit: NG 4222 XL / CP With SVK220

Max. input pressure (Bar): 3

Pressure drop, inlet and outlet (bar): 0.35

Inlet temperature (°C): 15-25

Average heat transfer to cooling water (kW): 26

Water content:

Cooling unit: 100

Chiller: 300

Water inlet / Outlet connection CP: 3/4" Female thread with hose nipple

Chiller water inlet / Outlet:

CWK90: 3/4" Female thread with hose nipple

SVK220: 1 1/4" Female thread with 3/4" hose nipple

Environmental conditions:

Ambient temperature (°C): 18 - 30

Max. relative air humidity during operation: 60% rel.

Max relative air humidity during transport: 80% rel. without condensate

Max altitude above sea level during operation [m]: 1,000

Electrical connections:

Voltage @ 50 Hz (V): 400 ±10%

Max pre fuse @ 50 Hz (V): 315

Voltage @ 60 Hz (V): 480 ±10%

Max pre fuse @ 60 Hz (V): 400

Earth method: TN-S

Connection: 3L+PE

Nominal power (kW): 175.

MEYER BURGER / SWISS SOLAR SYSTEMS / 3S NG 4222 XLCP is a highly advanced packaging equipment designed to increase the speed and efficiency of a packaging process. This system offers several advantages compared to manual packaging methods. The unit is designed to provide flexibility and maximum efficiency, allowing quick and precise packaging of a range of products. 3S NG4222XLCP offers several automated processes, including both loading and unloading of items. The machine's automated processes reduce the amount of human labor needed for the packaging process, as well as the time it takes to complete the task. MEYER BURGER NG4222 XL CP also offers several unique features. One of these is the automated magazine, which allows faster progression of product packaging. This magazine supplies the items to the handling unit, ensuring a more consistent workflow. Additionally, the tool has been equipped with a collection of sensors. These are strategically placed to detect the product and its related items during the process. Once detected, they are directed to the next station. The automated asset also includes a built-in error detection model and a self-diagnostic capability. This ensures that the equipment is functioning correctly and that all procedures are completed smoothly. 3S NG 4222 XLCP also has an intuitive interface. This allows users to easily configure settings and adjust the system's settings to their needs. Furthermore, the unit is also equipped with a safety shield which ensures secure operation and protects workers from potential dangers during the packaging process. Finally, MEYER BURGER NG4222XLCP is designed to be low maintenance, ensuring quick and easy maintenance and repairs. The machine's advanced design also ensures a long-lasting and reliable performance. Overall, SWISS SOLAR SYSTEMS NG4222XLCP is an advanced and efficient packaging tool designed to streamline the packaging process. Its intuitive interface, automated processes and error detection capabilities make it an ideal choice for businesses of all sizes.

There are no reviews yet