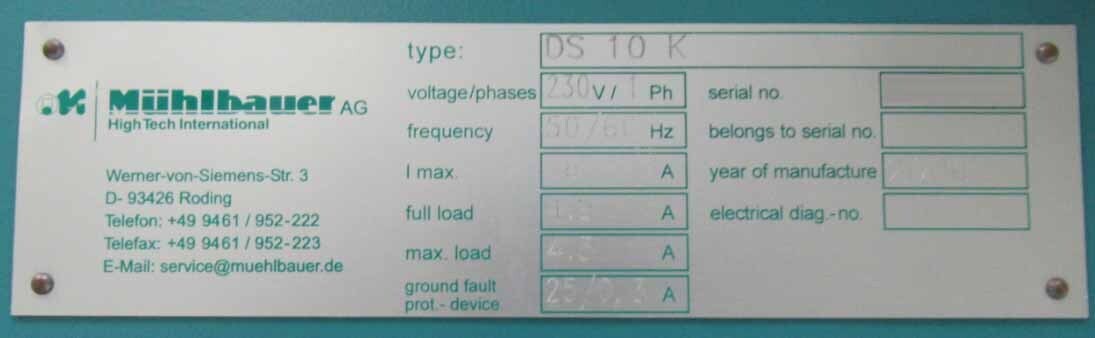

Used MUHLBAUER DS 10000 #9266255 for sale

URL successfully copied!

Tap to zoom

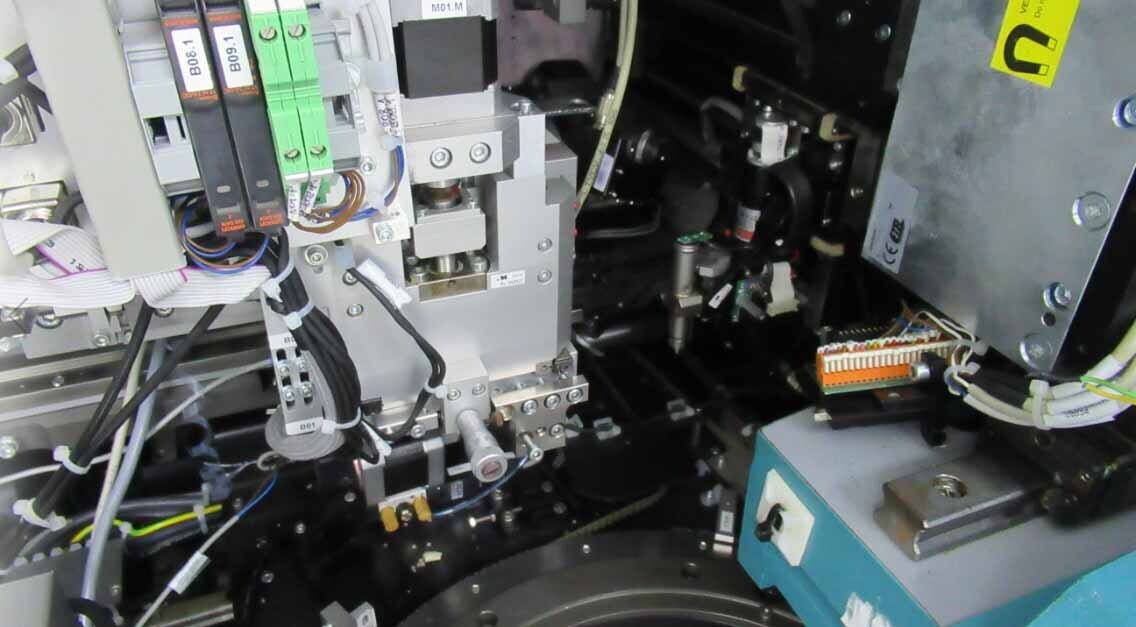

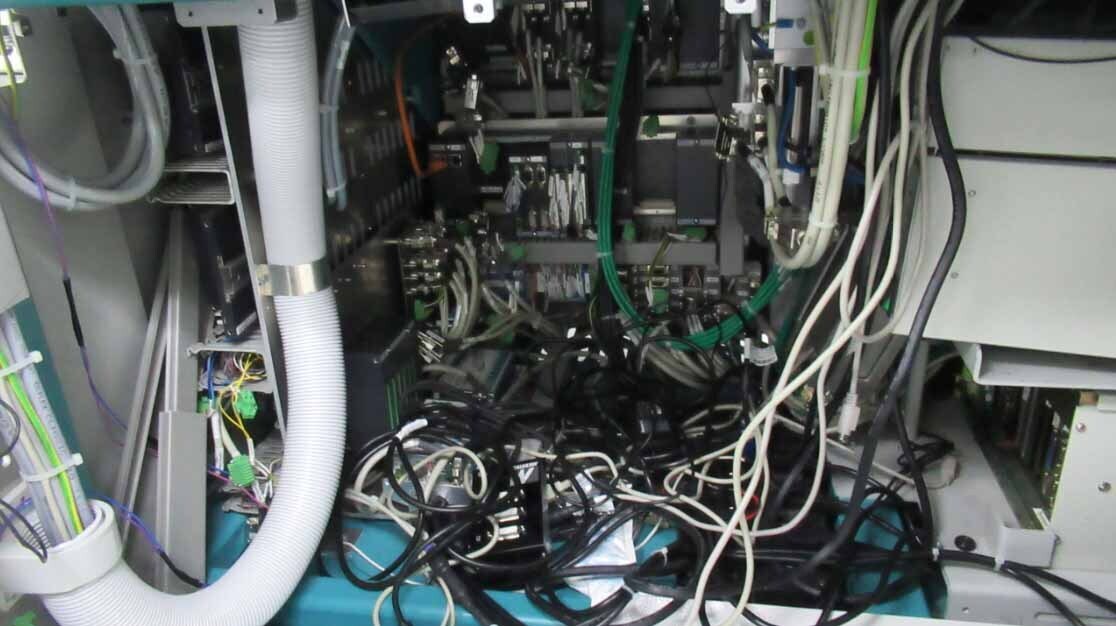

MUEHLBAUER DS 10000 is a fully automated, high-speed, and intelligent PC board assembly and manufacturing equipment. It is designed to be highly efficient, cost-effective, and reliable for a range of PCB assembly requirements. The system comes equipped with an intuitive, user-friendly interface for easy access and control of the individual elements of the assembly process. The control unit includes integrated functions such as part placement, fluxing, soldering, pick and place, conveyor transport, vision inspection, and test. MUEHLBAUER DS10000 is designed to work with both rigid and flexible boards, allowing it to be used for a wide variety of applications. The machine supports multiple device configurations, including DIP, AIML, SMD, and BGAs. It also supports multiple board thicknesses ranging from 0.5mm to 6.0mm, automatically adjusting to the specified thinnest dimension. DS 10000 is highly precise and consistent in its manufacturing, boasting positional accuracy of +/- 0.02mm. The tool has built-in self-diagnostics and is designed to be highly reliable for long-term operation. In addition, it is designed to be highly energy-efficient, with low power consumption and reduced operating costs. DS10000 is designed to be easily integrated into other production systems. It supports up to 25 lines, with multiple device transfer systems and a modular conveyor asset. The multiple device transfer systems are capable of auto-aligning, allowing for more efficient operation and easy integration into a high-volume PCB assembly line. Overall, MUEHLBAUER DS 10000 is an intelligent and efficient PC board assembly and manufacturing model designed to be highly effective and cost-efficient. It is designed to be reliable for long-term operation, energy-efficient, and easy to integrate into other production systems.

There are no reviews yet