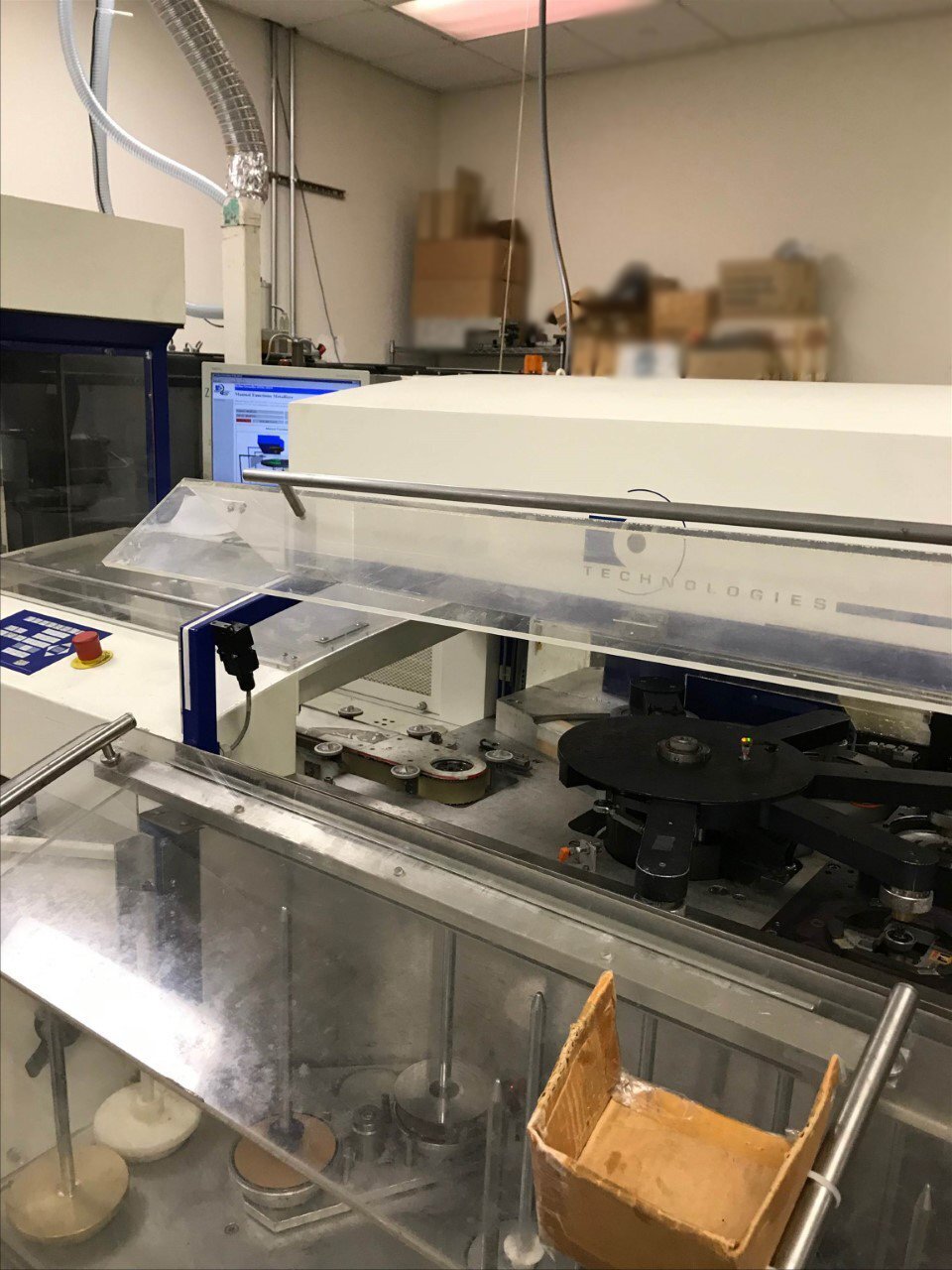

Used NETSTAL Discjet 600 #9351520 for sale

URL successfully copied!

Tap to zoom

NETSTAL Discjet 600 is a highly automated production equipment for the packaging of sensitive products. It is suitable for product containers such as bottles, jars, cans and tubs of up to 1.5 liters in size. This system is designed to offer an efficient and reliable solution for demanding production requirements. Discjet 600 uses an efficient, three-axis tangential carton forming unit with an easily adjustable feeder mechanism. This machine is designed to make efficient use of space, allowing the maximum number of products to be produced in the shortest possible time. The carton forming process involves placing the product into a flat paperboard blank, folding and gluing it into the desired shape. The tool is designed with a high-performance positioning asset and is equipped with an electronic cleat feeder. This ensures that all of the cartons are accurately filled and are able to withstand the rigours of the packaging process. The feeder also ensures that the products are loaded onto the belt conveyor in an orderly fashion and at the correct orientation for the next stage of the packaging process. NETSTAL Discjet 600 features a servo-driven hot melt model for sealing adjacent cartons together. This ensures that the product is effectively sealed and protects the product from external contaminants. The hot melt equipment also ensures that the product is secure and stable during handling, storage and delivery. Finally, Discjet 600 offers the highest levels of quality in its output. This is achieved through its built-in vision system, which monitors the progress of each and every carton. This unit is designed to check for misalignment, incorrect shapes and incorrect fill depths. It will also check for any damage which may have occurred during the manufacturing process and reject any damaged cartons. In summary, NETSTAL Discjet 600 is a highly automated production machine for the packaging of sensitive products. It is designed with a high-performance positioning tool, an electronic cleat feeder, and a servo-driven hot melt asset for sealing adjacent cartons together. This ensures that the product is secure and stable and that the highest levels of quality are achieved in the packaging process.

There are no reviews yet