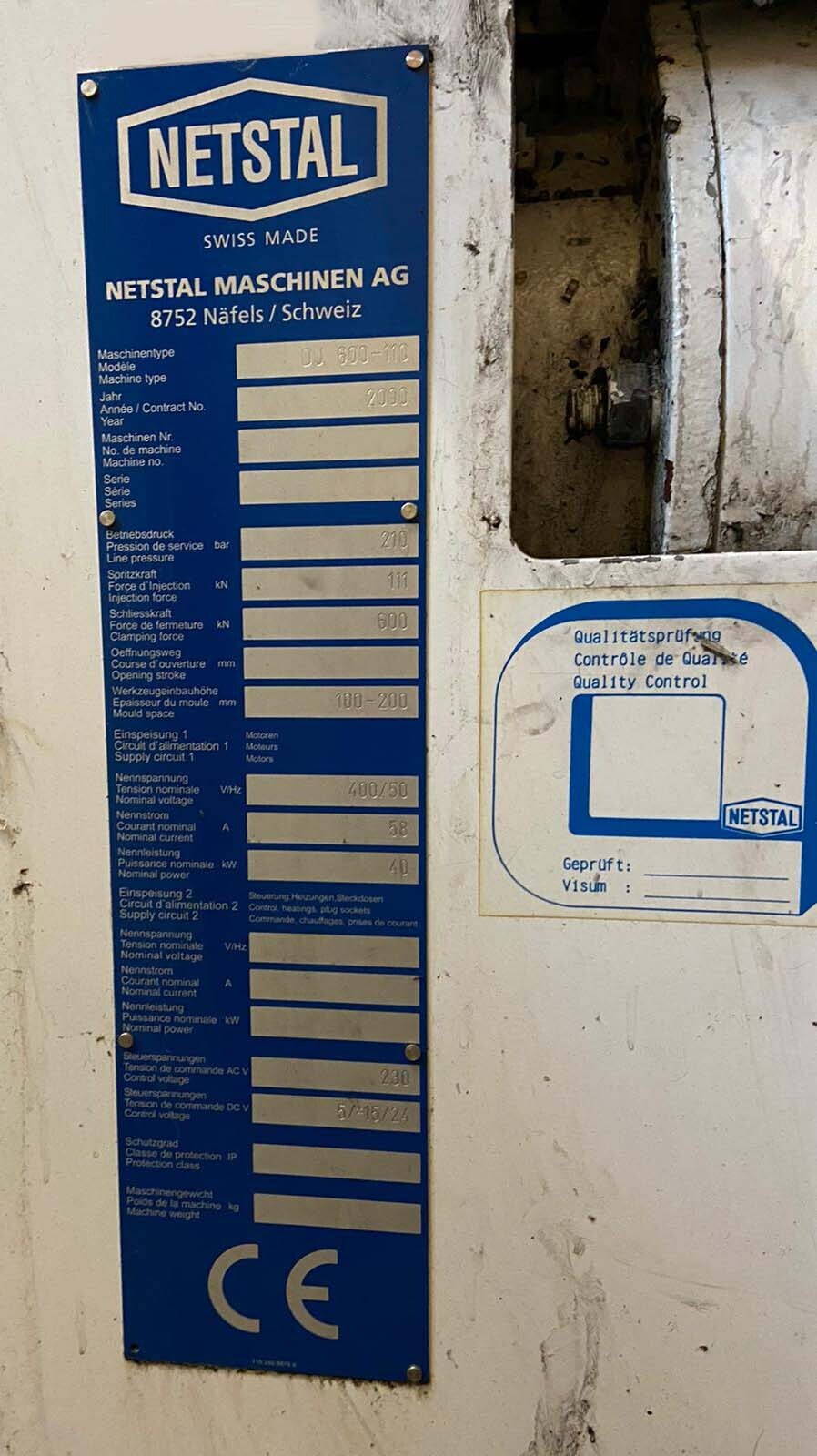

Used NETSTAL DJ600 / 110 #9199365 for sale

URL successfully copied!

Tap to zoom

ID: 9199365

Vintage: 2000

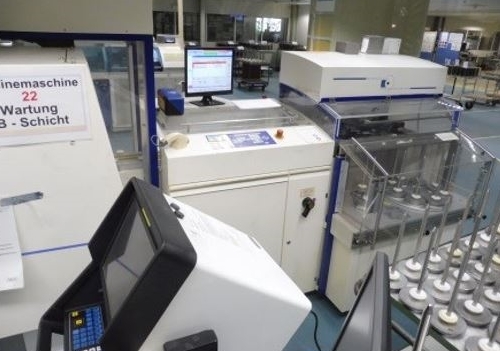

CD Replication system

With hydr

Injection force: 111 kN / 11.1 t

Clamping force: 500 kN / 50 t

NETSTAL Sycap control

Suction conveyor

Material hopper

With fan heater

WITTMANN / DISCO Control unit

Temperature control unit

SINGULUS Skyline surface treatment unit

Handling

Metallizing unit

Painting unit

UV Curing unit

Scanning system / Output unit

Modules:

Clean air

Underground sensor

2000 vintage.

NETSTAL DJ600 / 110 is a high-performance packaging equipment for a wide range of applications, making it ideal for medium to high volume production. It is powered by a robust and reliable low energy drive system, enabling it to deliver optimal performance, accuracy, and efficiency for every application. The unit is designed to both increase production output and reduce material waste while keeping maintenance and running costs to a minimum. The drive machine allows for a flexible package design, allowing for customized performance and a wide range of products to be quickly created. The machine is equipped with a host of innovative features that make it easy to use, including a color touchscreen interface that is easy to comprehend and use. The quick-change inserts, powered turret, and pneumatically operated tooling provide a reliable base for a variety of packaging operations. The integrated contact-less sensor tool ensures accurate package heights and positions. The robust, high-performance servomotors drive the synchronously operated index drive, delivering a precise and repeatable packaging process. DJ600 / 110 is also designed for low environmental impact, with an eco-friendly cooling asset, low power consumption, and minimal amount of noise and vibration. Clippard valves and high responsiveness allow for efficient start/stop times, greatly reducing material waste. It also meets the latest safety regulations and standards, making it a safe and secure choice for any production. The model is user friendly and highly versatile, allowing users to easily switch between primary, secondary and tertiary packaging formats. The machine is bedded to ensure precise mounting, and can be configured as needed for the specific application. It also offers a high degree of accuracy, speed, and repeatability, and can be integrated with existing systems, making it suitable for labelling, coding, and other automation purposes.

There are no reviews yet