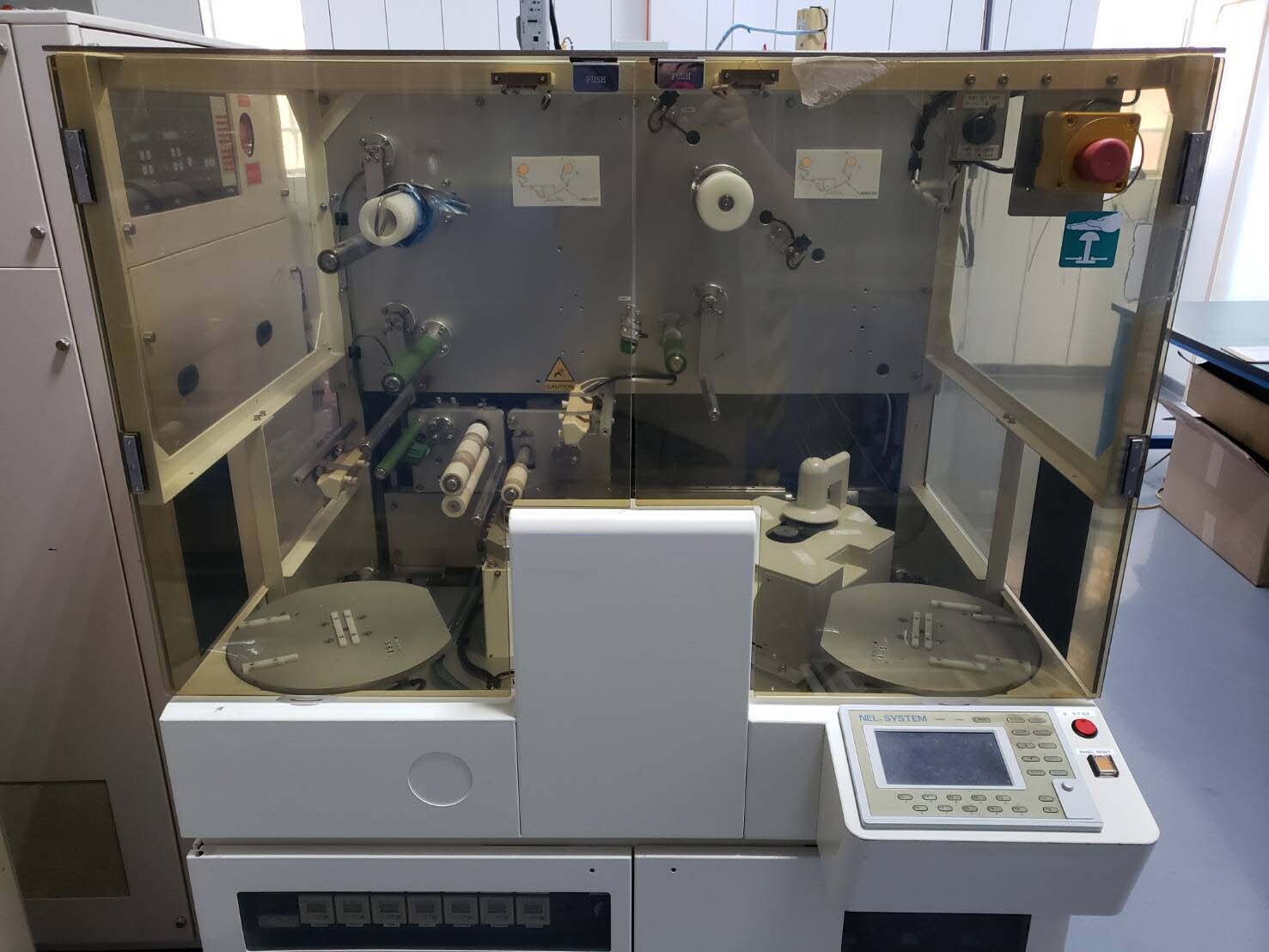

Used NITTO DENKO NEL SYSTEM HR 8500 II #293608904 for sale

URL successfully copied!

Tap to zoom

ID: 293608904

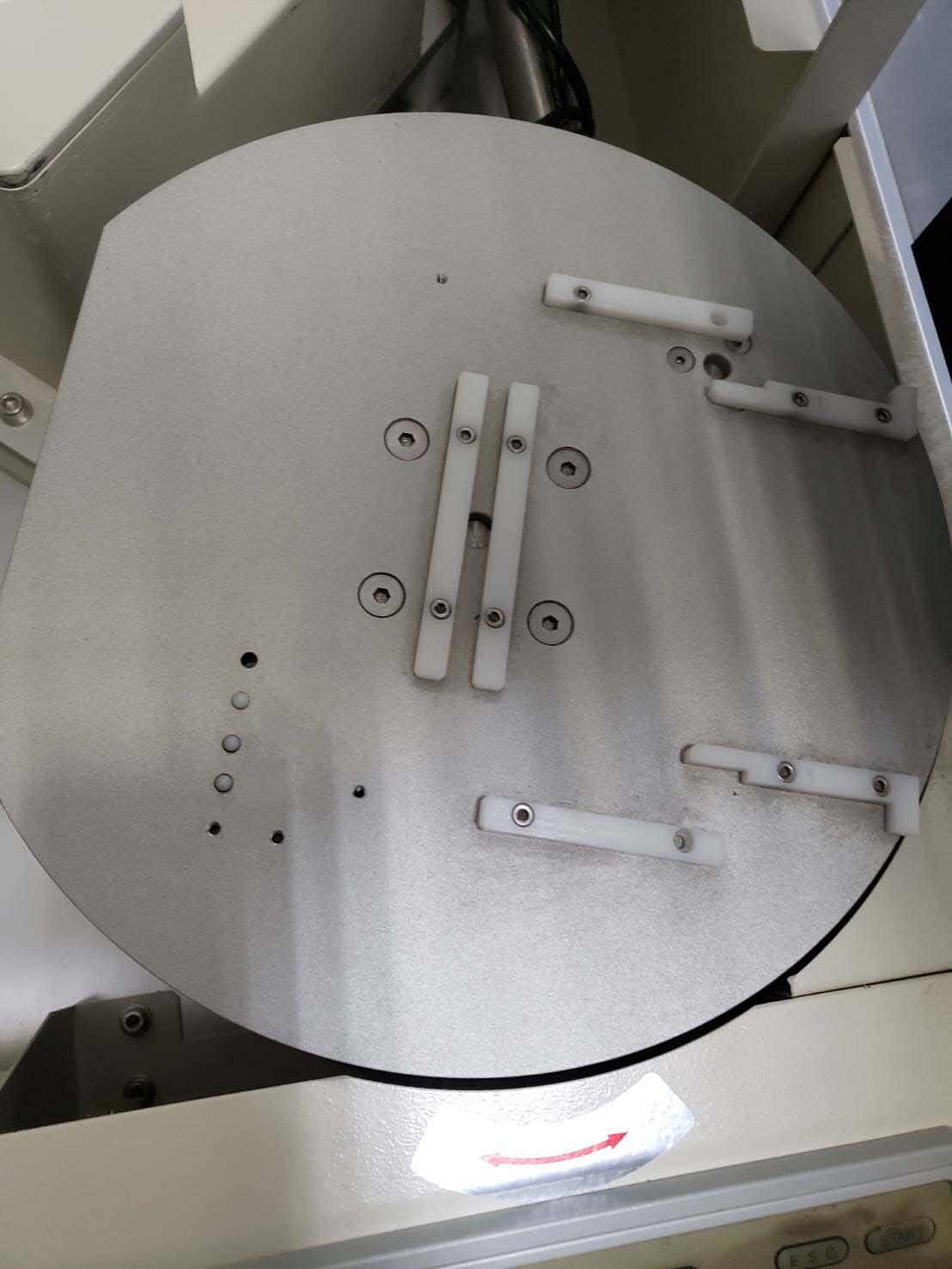

Wafer Size: 8"

Vintage: 1995

Taper, 8"

Without UV System

Wafer thickness: 300 - 1000 µm

Power supply: 120 V AC

1995 vintage.

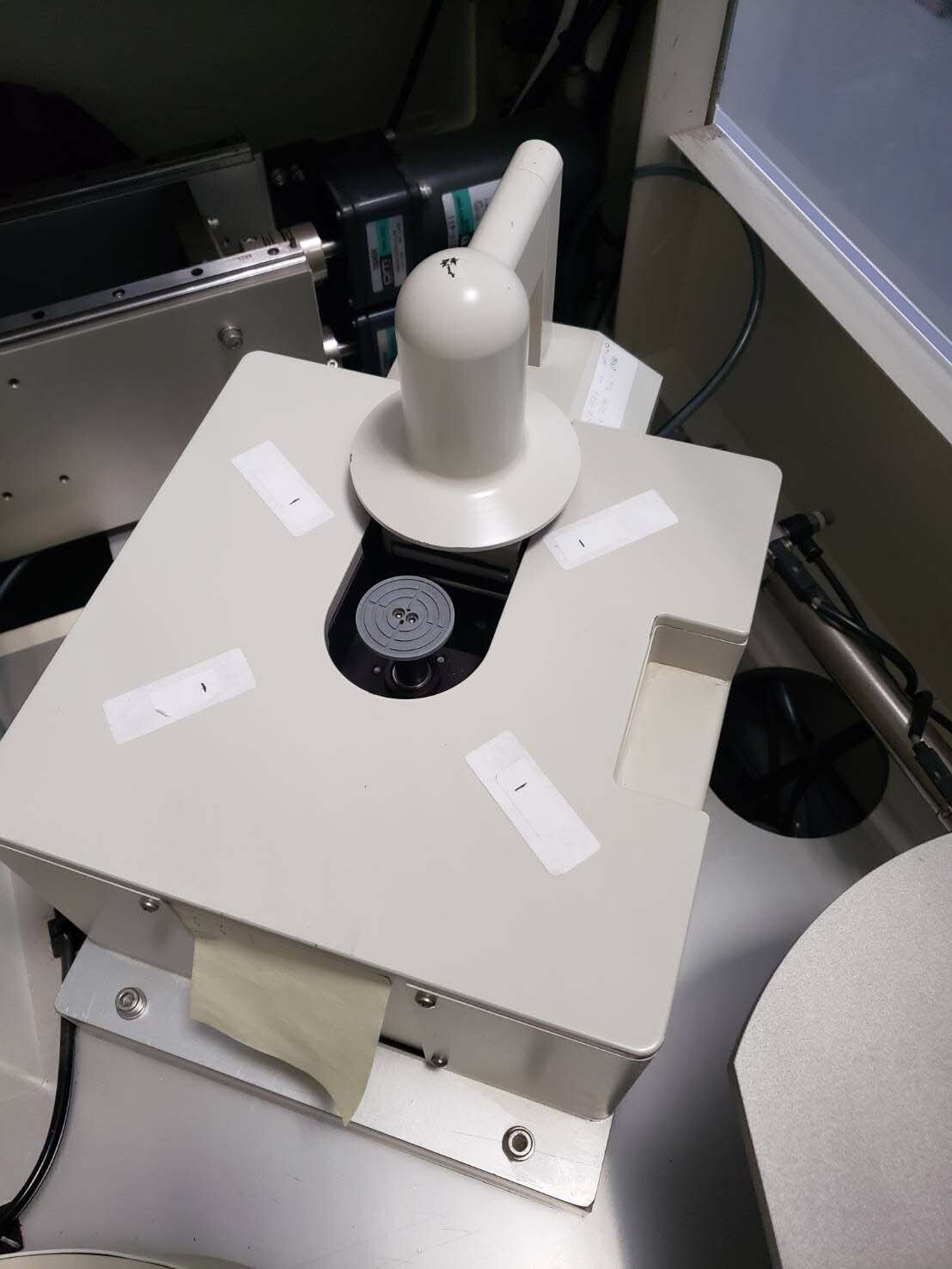

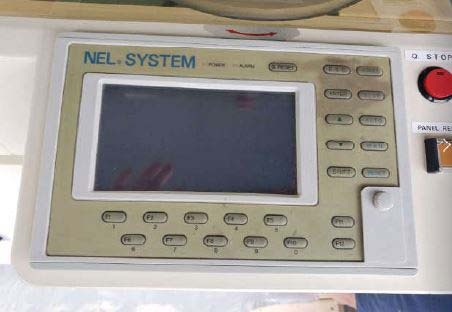

NITTO DENKO NEL Equipment HR 8500 II is an end of line packaging system that offers fast and efficient shrink sleeve labeling for a variety of products. This unit is designed to accommodate a wide range of containers, from small bottles to large kegs, with high levels of accuracy. The standout features of this machine are its fast labeling speed and soft gripper technology for flexible handling of different sized containers. To operate NITTO DENKO NEL Tool HR8500-II, the product to be labeled is placed on a shelf which is then presented to an image recognition device. This device reads the product's unique code and sets the proper labeling parameters. Once the parameters are set, the product is transferred along the conveyor to the label applicator. HR-8500-II includes both servo-driven and pneumatic label pneumatics, allowing for higher speeds and precise accuracy. HR 8500 II is equipped with an advanced shrink sleeve label applicator. This asset offers multi-platen film shrink sleeve labeling which simultaneously applies labels to multiple containers at each cycle. HR8500-II also features its QandELTM soft-gripper technology, which accurately and delicately handles fragile containers such as bottles with extended necks. This model features a high-grade external waggler for precise alignment and accurate registration of pre-printed label patterns. To accurately inspect the finished product, NITTO DENKO NEL Equipment HR-8500-II is equipped with an automated inspection bay with camera imaging sensors and a custom labeling software package. This ensures that each sleeve is securely applied and all codes are accurately printed. The system includes an optional sorting hopper which automatically sorts rejected containers. Overall, NITTO DENKO NEL Unit HR 8500 II is an advanced and reliable solution for packaging line automation. It combines precision labeling with cutting-edge image recognition, soft-gripper technology, and automated inspection to create an efficient and cost-effective machine that can be easily integrated into existing operations. In addition, the machine is efficient and easy to use, making it an ideal choice for those looking to automate their packaging process.

There are no reviews yet