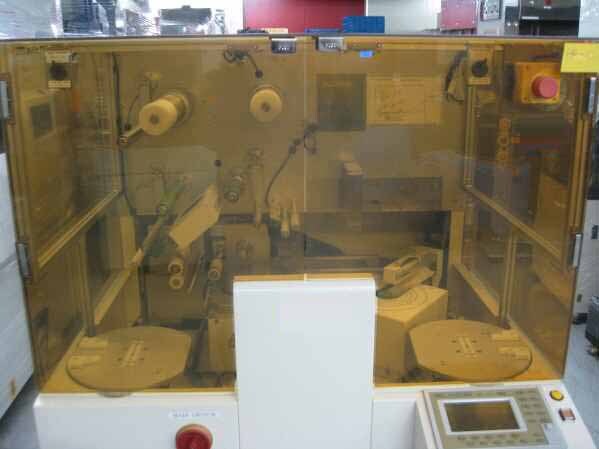

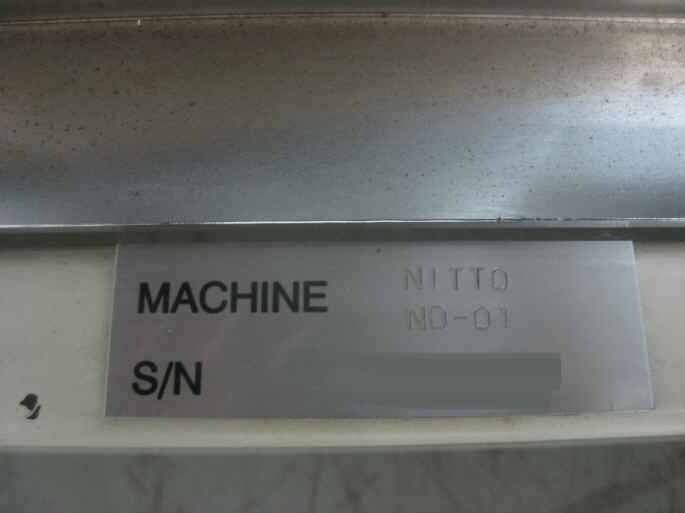

Used NITTO DR 8500 II #9038102 for sale

URL successfully copied!

Tap to zoom

ID: 9038102

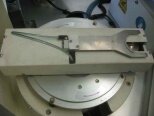

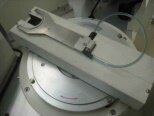

Wafer Size: 8"

Vintage: 1994

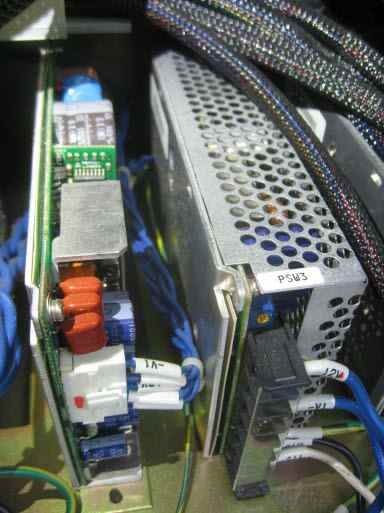

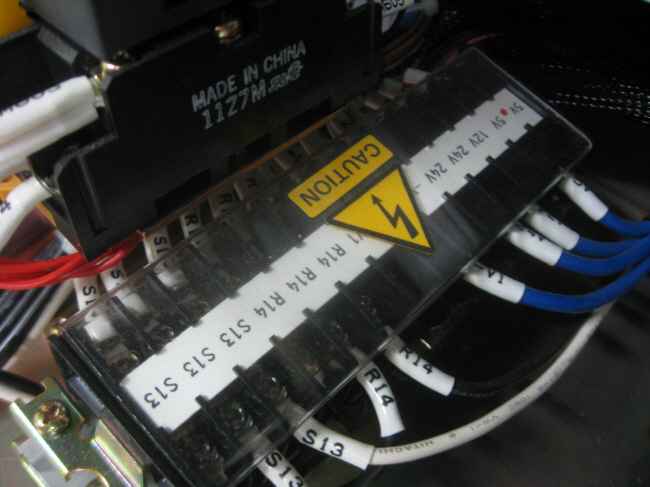

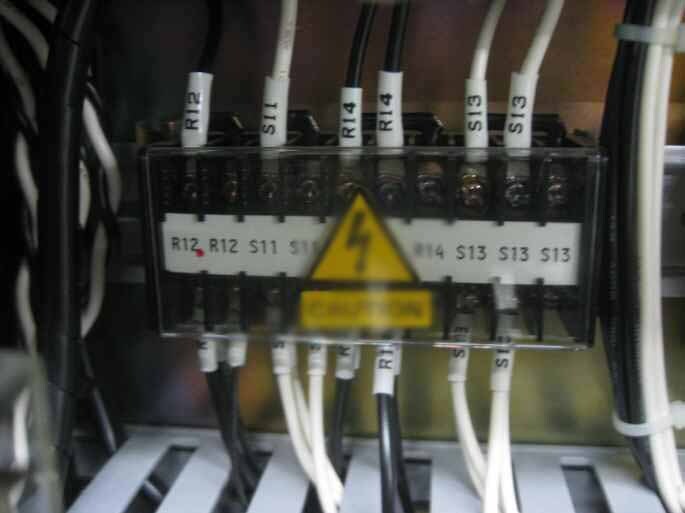

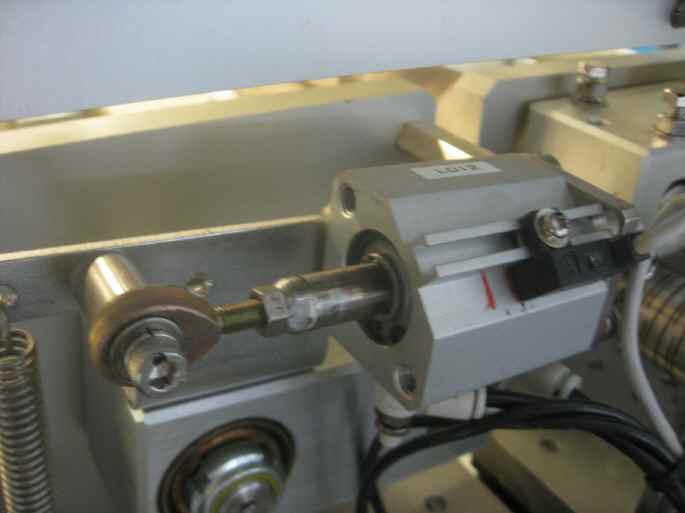

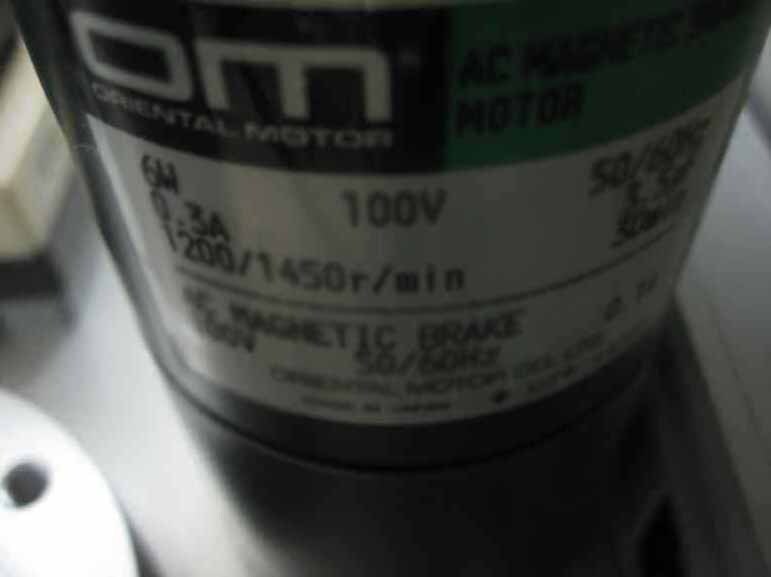

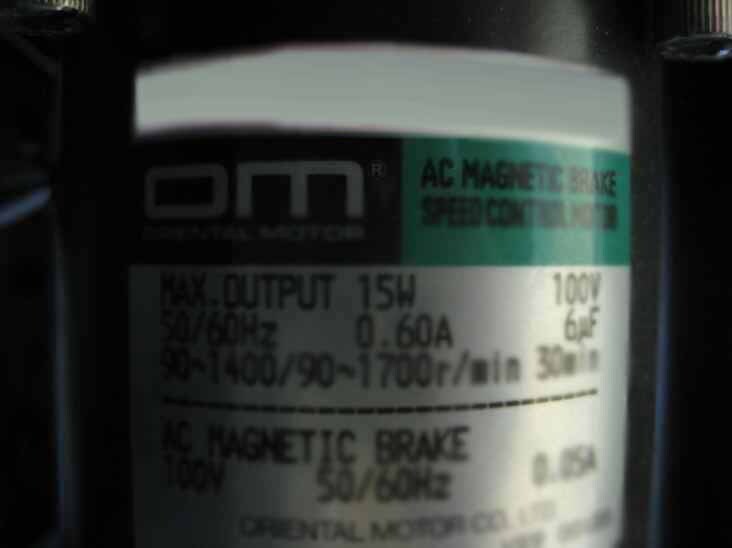

Detaper, 8"

Missing part:

NIL Touch panel controller

1994 vintage.

NITTO HR 8500 II is an automated packaging equipment designed to optimize the packaging of products by drastically reducing labor costs and time. This system has a high efficiency and more flexible operation which provides businesses with the ability to package a variety of products in one machine. In order to provide this increased flexibility, NITTO HR8500-II has a unique design featuring three distinct sections: a power-lifting feeder, a weighing-dispensing mechanism, and a wrap-around conveyor. The power-lifting feeder is responsible for moving the product from bulk storage to the scales, with minimal manual help from operators. This feeder is suspended from the ceiling and features an automated lift unit that moves the load throughout the factory floor. The unit is designed to operate with multiple materials, from cartons to poly bags. Weighing-dispensing mechanism is used to accurately weigh Single Piece Flow (SPF) products. This unit accurately measures the weight of a product and stores the measurement for use by the packaging machine. Thewrap-around conveyor is used to move the products from the weigh-dispense mechanism to the wrapping station. This conveyor is able to accommodate products of all sizes, shapes and weights, allowing the tool to be quickly configured for the packaging of a wide range of products. The automation capabilities of HR 8500-II are further enhanced with the integration of a high-performance wrap-around asset. This model is designed to accurately wrap products in a short amount of time. This equipment also minimizes the time needed to package products by utilizing advanced air and liquid conveyors, as well as laying a protective film over the wrapped product before transporting it away from the wrap-around station. The machine is equipped with the latest safety features, from mesh guarding and crash protection, to a Programmable Safety Computer (PSC). This safety system provides the greatest level of automated safety for operators and products alike. The PSC is specifically designed to detect any potential dangers, such as sudden stopping, or changes in speed or direction, and immediately alert operators and supervisors. NITTO HR 8500-II is designed to provide businesses with a highly efficient, automated packaging solution. With its integrated power-lifting, weighing-dispensing, and wrap-around conveyor systems, the unit offers a comprehensive package in the automation of product packaging. Furthermore, the unit is exceptionally efficient and cost-effective, reducing operating costs and increasing efficiency overall. HR 8500 II is the ideal solution for any business looking to increase their packaging efficiency.

There are no reviews yet