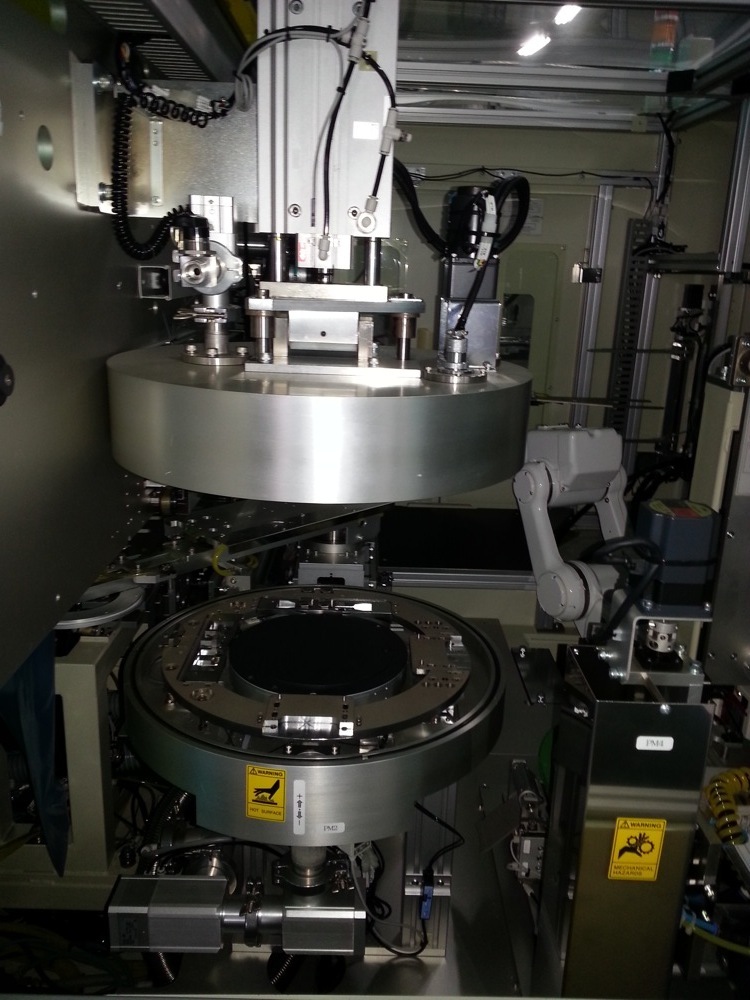

Used TAKATORI ATM 12000DR #9072324 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9072324

Detaper, 8"-12"

Throughput: 60 wafers/hour (inline with B/G 25 wafers/hour)

Wafer thickness: 300-740 micron (inline with B/G 150-740 micron)

Wafer cassette: 1 set

Power supply: AC200V 3 phase, 50/60 Hz

Air supply: 0.4~0.5 Mpa

2004 vintage.

TAKATORI ATM 12000DR is a robotic packaging equipment designed to automate the palletizing process. This automated palletizing system can package a variety of products, such as single packs of food items, beverages, and other items. It can also package products in mixed pallets with different products in different positions. It features an integrated robotic arm, gripper unit, camera sensors, and a programming interface that makes it easy to configure the machine to specific needs. The tool includes collaborative functions to prevent unintentional engagement of a robot and an operator, while also ensuring safe operation overall. The main body of ATM 12000DR is an aluminum extrusion frame and carriage. The frame and carriage provide the housing and overall support structure for the entire asset. It has an integrated scratch-resistant coating and includes adjustable feet to provide a stable base. TAKATORI ATM 12000DR is equipped with reliable servomotors and linear modules to power its robotic arm and gripper model. The slew of motors greatly improves the speed and accuracy of the equipment while also providing a robust construction that is resistant to damage. It has a five-axis arm that can move quickly and accurately in all x, y, and z directions as well as as-defined orientations. It also has two-axis rotary actuators to control the angle of the gripper. A 5-point screw-in laser system is used for distance and alignment measurements, so the unit knows where to place the product and can verify that the product is within close proximity of the gripper. An integrated camera machine is used to detect the location and size of products. It captures images and sends them to ATM 12000DR for analysis and for automatic alignment of products in the gripper. The tool has a programming interface with an intuitive graphical user interface, making it easy for the user to control and program the machine. It includes support for programming languages such as C# and Python so the user can create custom scripts and program the robot to interpret and act on input from its sensors. TAKATORI ATM 12000DR is designed to operate quickly and accurately while being safe for both operators and the products themselves. It includes a full set of safety features, such as a polycarbonate transparent guard to protect Humans from the robotic arm. It also has a high-frequency sensor to detect any objects in the palletizing area and prevent the robot from moving and crushing them. Additionally, the collaborative functions allow the robot to pause its cycle if it senses an operator in the vicinity and automatically resume its cycle once the operator is clear. Overall, ATM 12000DR is a powerful and reliable automated palletizing asset. It is designed to provide precise and safe performance, while also allowing the user to customize it to their specific requirements.

There are no reviews yet