Used AIRVAC / ZEVAC DRS 22 #9203427 for sale

URL successfully copied!

Tap to zoom

ID: 9203427

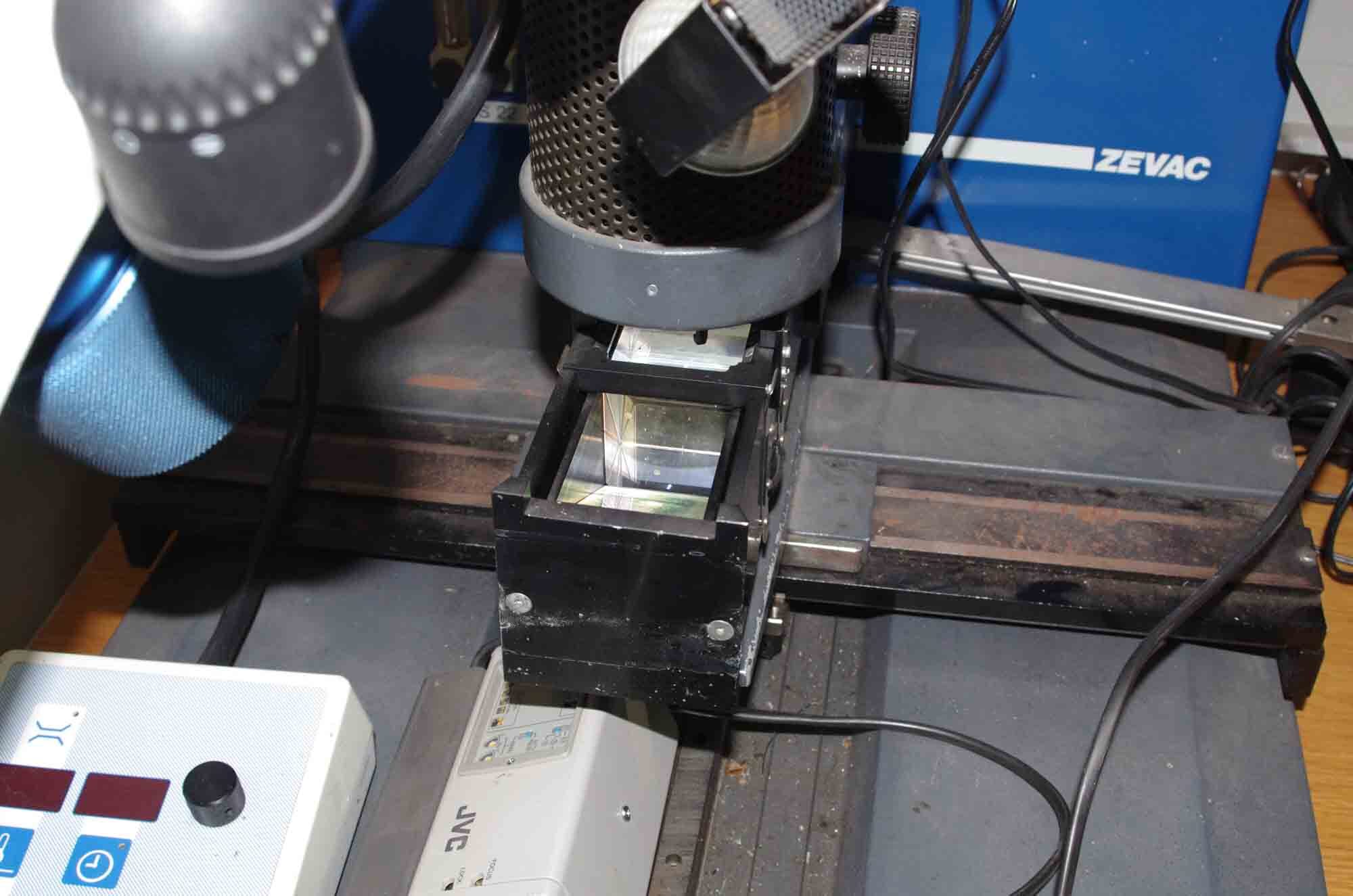

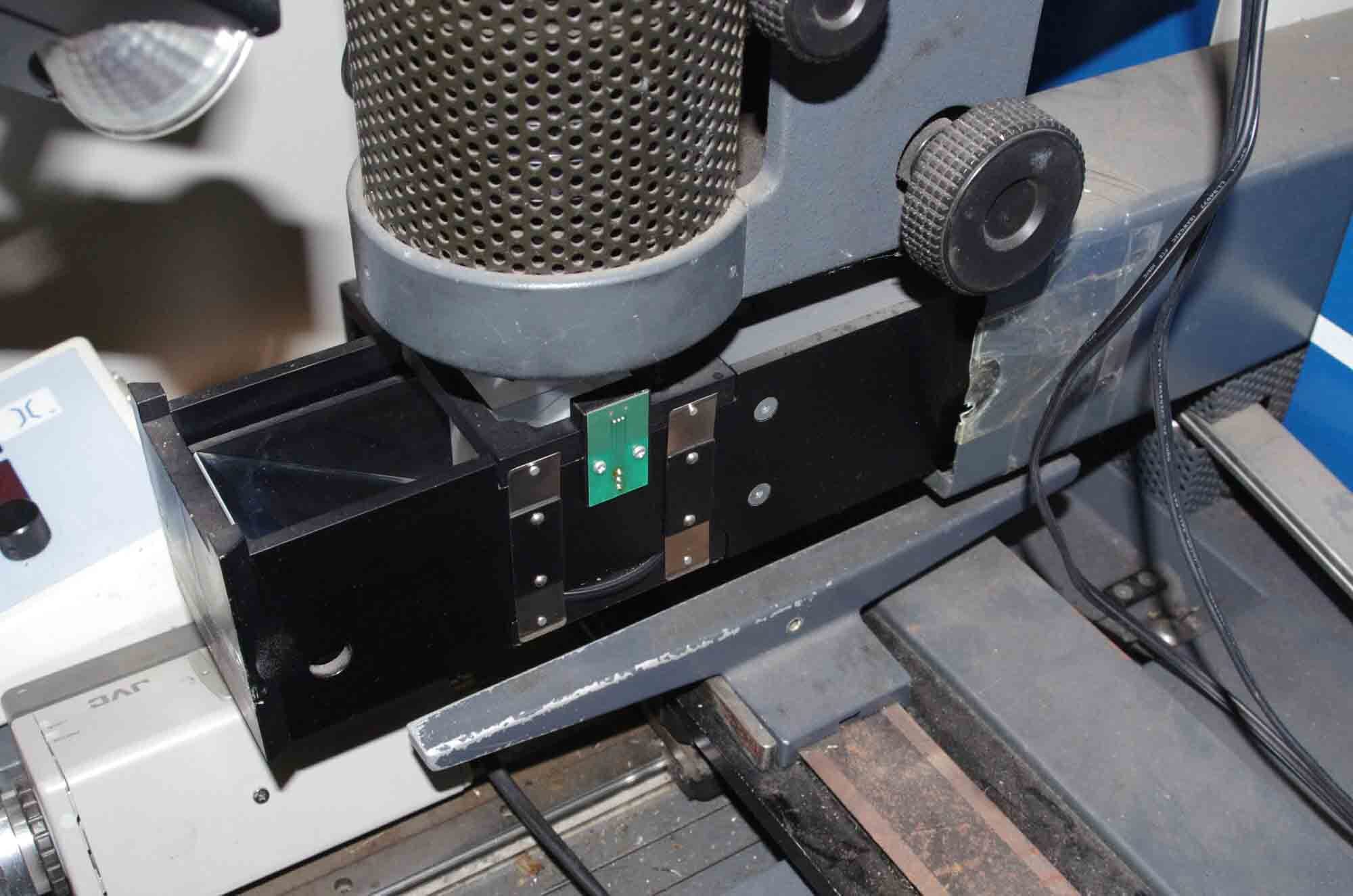

BGA Rework station

Camera

Split image optics

Optical alignment

Power: 240VAC.

AIRVAC / ZEVAC DRS 22 equipment is a PC board assembly and manufacturing system used for the production of printed circuit boards (PCBs). It is a sophisticated, high-speed unit that automates the entire PCB production process, taking a board design from concept to completion. The machine is comprised of several components. At the heart of the tool is ZEVAC 22 PC board assembly printer. This printer is capable of producing single- or double-sided PCBs, up to 40" x 60" in size. It is designed to work with a variety of different media, such as FR-4, polyimide, Mylar and adhesive-backed laminates. The print head is designed to provide superior accuracy and speed, and is capable of printing up to 250,000 possible layers. The asset also features an automated substrate placement machine that is capable of placing components with impressive accuracy and precision. It can handle components of up to 0.02mm in pitch and 0.012mm in size (0.006mm in height). ZEVAC DRS 22 model also features an in-house inspection, testing and repair station. This allows the equipment to automatically identify and fix any defects or inconsistencies that may be present in the finished product. Other features of the system include an onboard vision unit and rating machine, as well as a sophisticated data logging module. The vision tool and rating asset are designed to provide feedback on quality assurance and product performance, while the data logging module allows for the analysis of real-time production data. Overall, AIRVAC DRS 22 model is an ideal choice for PCB assembly and manufacturing. Its advanced components, user-friendly design and superior accuracy make it an excellent choice for a wide variety of applications. Thanks to its automated features, this equipment is able to deliver exceptional results, while minimizing downtime and maintenance costs.

There are no reviews yet