Used AIRVAC / ZEVAC DRS 24 #9296401 for sale

URL successfully copied!

Tap to zoom

ID: 9296401

Vintage: 2007

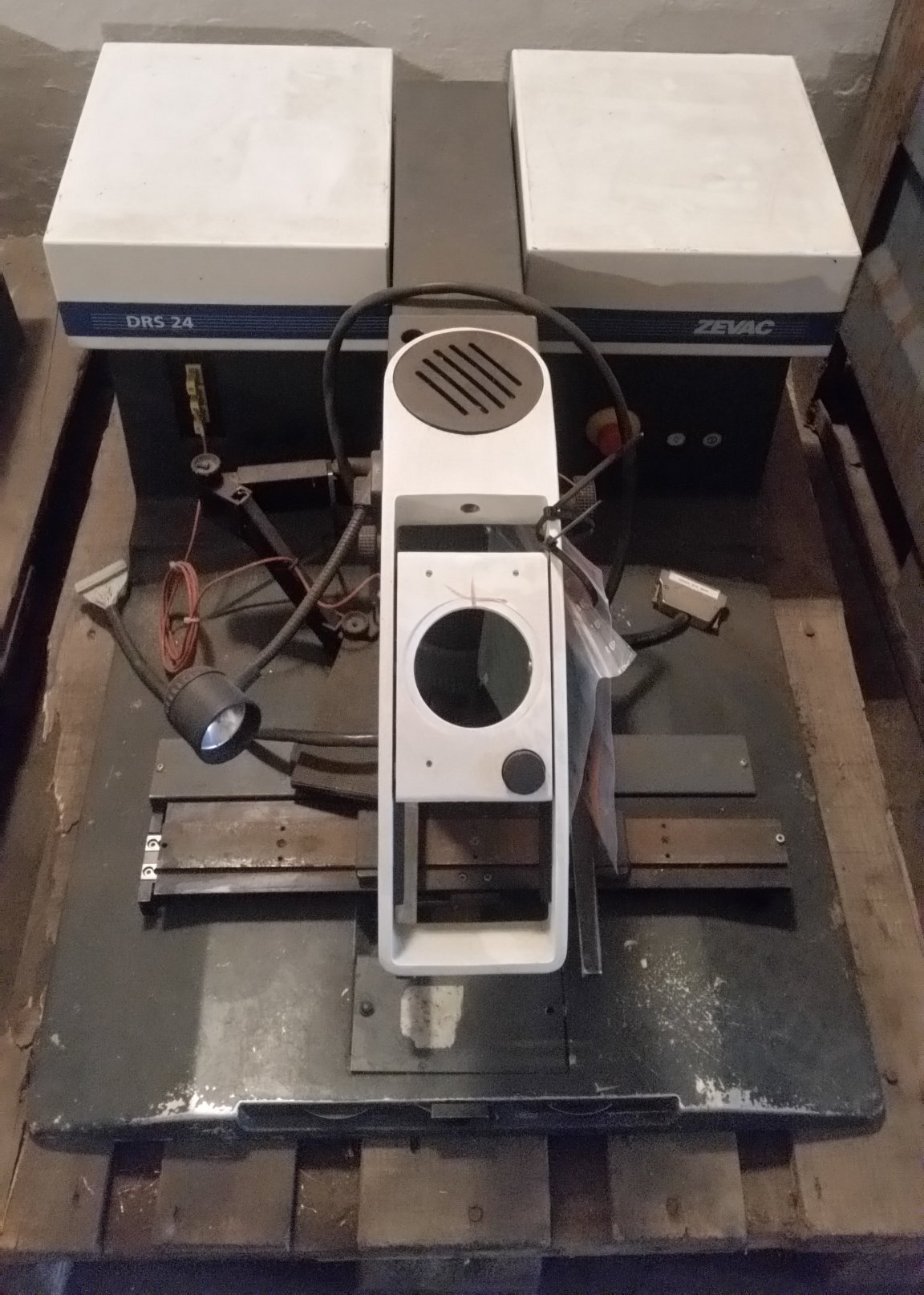

BGA Rework stations

Motorized vision / Z-Axis

PCB

Cross table with adjustment

Hot gas nozzle

Stereo microscope

Lighting

Vertical adjustment

Gas flow indicators: Gas nozzle and preheater

Print holder

Heating head angle adjustment

Microscope tilt angle: 45° to 60°

Heating head angle adjustment: ±10°

Compressed air connection: 4 - 6 Bar

Temperature: 150°C to 420°C

Medium heat transfer: Gases (Compressed air and Nitrogen)

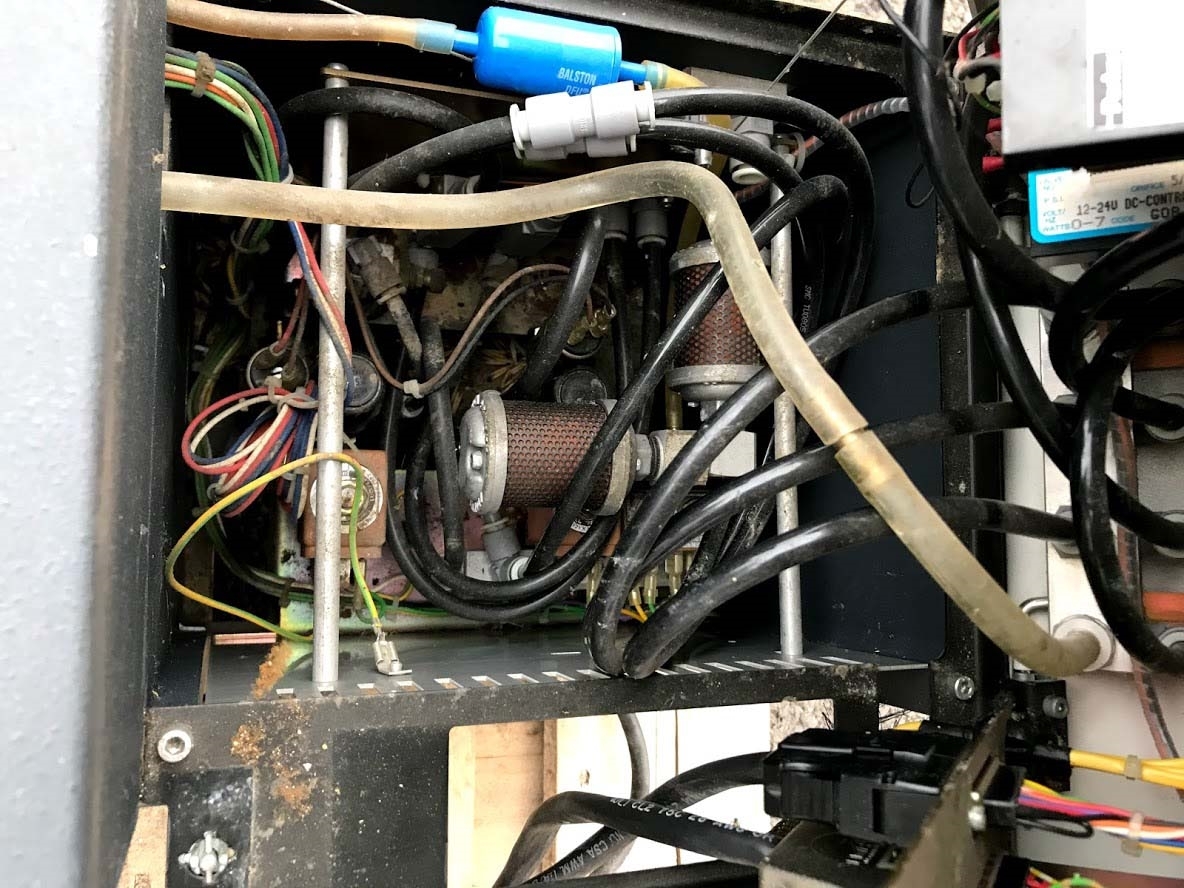

Missing parts:

Foot switch

Hand controller

Power supply: 220-230 V, 2300 W, 50/60 Hz

2007 vintage.

AIRVAC / ZEVAC DRS 24 is a PC Board Assembly and Manufacturing equipment designed to automate and streamline the process of creating custom printed circuit boards (PCBs). This integrated solution is capable of performing a wide range of tasks including soldering, precision assembly, and more. The system is equipped with a powerful 24-channel digital relay unit which provides the control and accuracy required for complex PCB layouts. Additionally, advanced diagnostics, ESD protection, and in-line test systems are included to ensure consistent quality standards are met. ZEVAC DRS 24 machine is extremely versatile and capable of manufacturing a wide variety of PC board types and layouts. It includes programmable nozzle holders for the user's convenience, allowing them to quickly customize the tool for a variety of surface-mount components. The asset is capable of soldering components without the need for additional fixtures, and can even solder components on the bottom layer using a dedicated soldering nozzle. This means that users have the flexibility to modify their manufacturing process on the fly without having to commit to a specific layout beforehand. AIRVAC DRS 24 also comes standard with a variety of other features that make PCB assembly much more efficient. The model is designed with an integrated smart-feeling component placer and uses built-in camera technology to accurately verify component placement. It also includes a fully programmable optical assembly equipment for component placement, an integrated laser depaneling system for larger boards, and the ability to integrate a wide variety of inspection and testing systems. DRS 24 is a highly advanced, specialized unit for PCB assembly and manufacturing. Its modular design allows for quick and easy integration into existing production lines, and boasts a range of features that make it well suited for both high-volume production and complex designs. Its digital relay machine ensures accuracy and repeatability, while its programmable tooling tool gives users the flexibility to quickly switch layouts and components without extensive setup. In addition, the asset is designed with advanced diagnostics and in-line test systems to ensure high quality manufacturing and consistent PCB quality standards.

There are no reviews yet