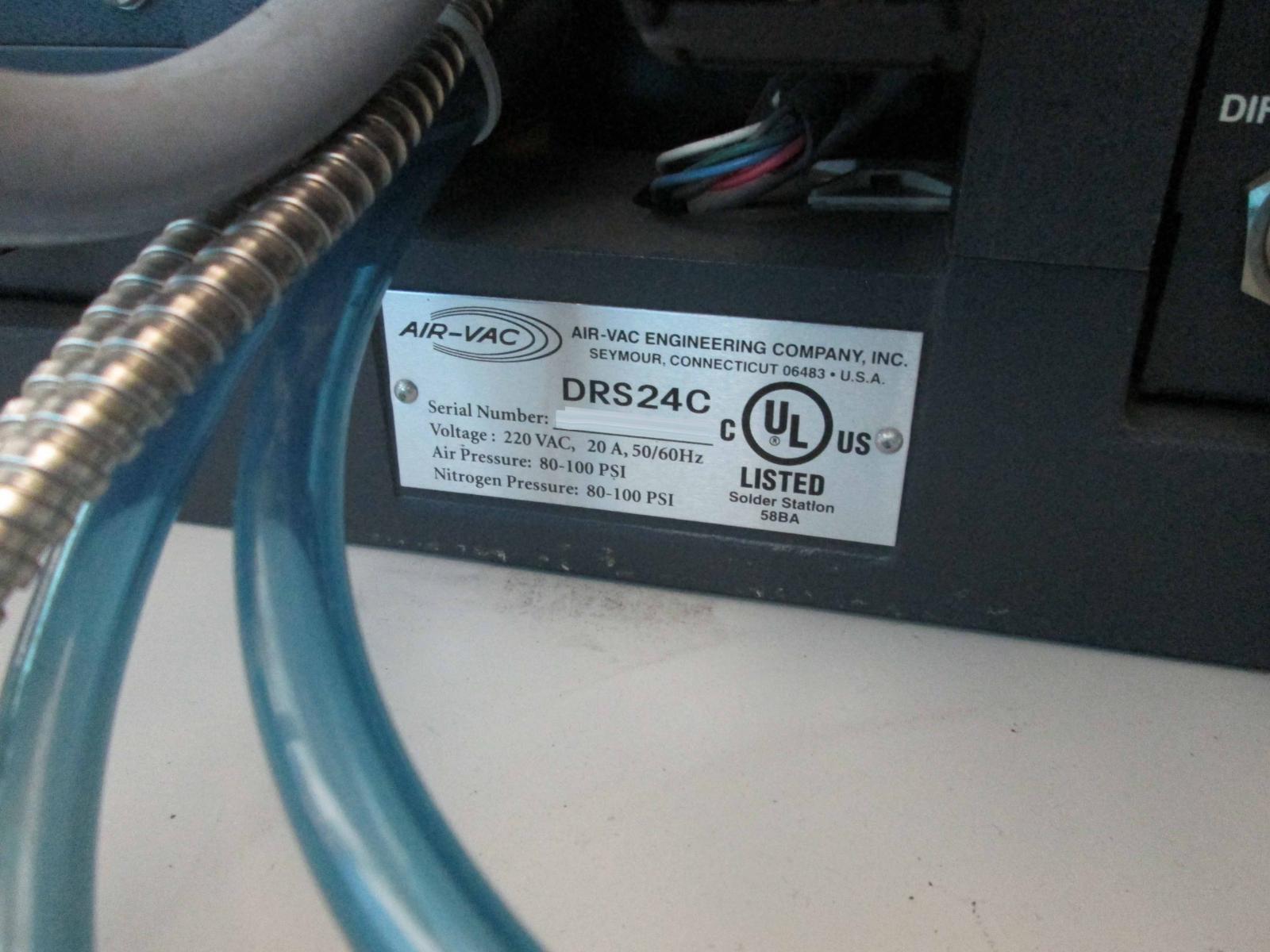

Used AIRVAC / ZEVAC DRS 24C #9176981 for sale

URL successfully copied!

Tap to zoom

ID: 9176981

Rework station

With double bottom diffuse

(6) Nozzles

Standard board size: 18" x 24"

Bottom heater: 12" x 20"

Dual zone convection

Preheater (4000 watts)

Clearance (Top / Bottom): 0.92"/1.0"

Viewing angle: 45°-60°

Theta rotation: +/- 10°

Air / Nitrogen requirement:

Bottom heater: 90-130 Psi @ 25 scfm

Upper heater: 90-130 psi @ 3 cfm

Currently crated.

AIRVAC / ZEVAC DRS 24C is a pc board assembly and manufacturing equipment that is designed to provide high-speed efficient automation to the production of printed circuit boards. Using the latest in design and fabrication technology, ZEVAC DRS 24C system is capable of producing up to 35,000 boards per hour with a high level of accuracy and repeatability. The unit is designed to process boards with various sizes, shapes, and designs quickly and accurately without the need for manual handling. AIRVAC DRS 24C comprises of four main components: the main computer controller and designed software, pick and place unit, the vision inspection unit, and the reflow soldering unit. The main controller includes an industrial grade computer, accompanied by software designed to monitor the pick and place unit, the vision inspection unit, and the reflow soldering machine. This allows users to keep track of the board production process and ensures maximum efficiency and quality. The pick and place unit is capable of placing components with a high degree of accuracy and repeatability. The unit also includes sensors and vision processors that enable it to sense and identify components on the board. After being picked from the feeders, these components are mounted onto the board with high precision. The vision inspection unit is designed to check the boards for errors or inconsistencies. This unit provides the accuracy and reliability needed to ensure that each board is placed correctly. With its high speed and accuracy, any errors or inaccuracies can be identified quickly and corrected before the board is sent for reflow soldering. The final component of this tool is the reflow soldering unit. This unit is designed to provide quick and efficient soldering for each board. By controlling the temperature and speed of the reflow solders, this unit ensures a high degree of quality and accuracy for each board. DRS 24C is an ideal solution for high-volume production operations where high-speed and accurate fabrication and assembly is required. By combining these four components, the asset is able to provide reliable and efficient automation for printed circuit boards. With its high speed and accuracy, AIRVAC / ZEVAC DRS 24C model is an ideal solution for companies looking for reliable and efficient pc board assembly and manufacturing.

There are no reviews yet