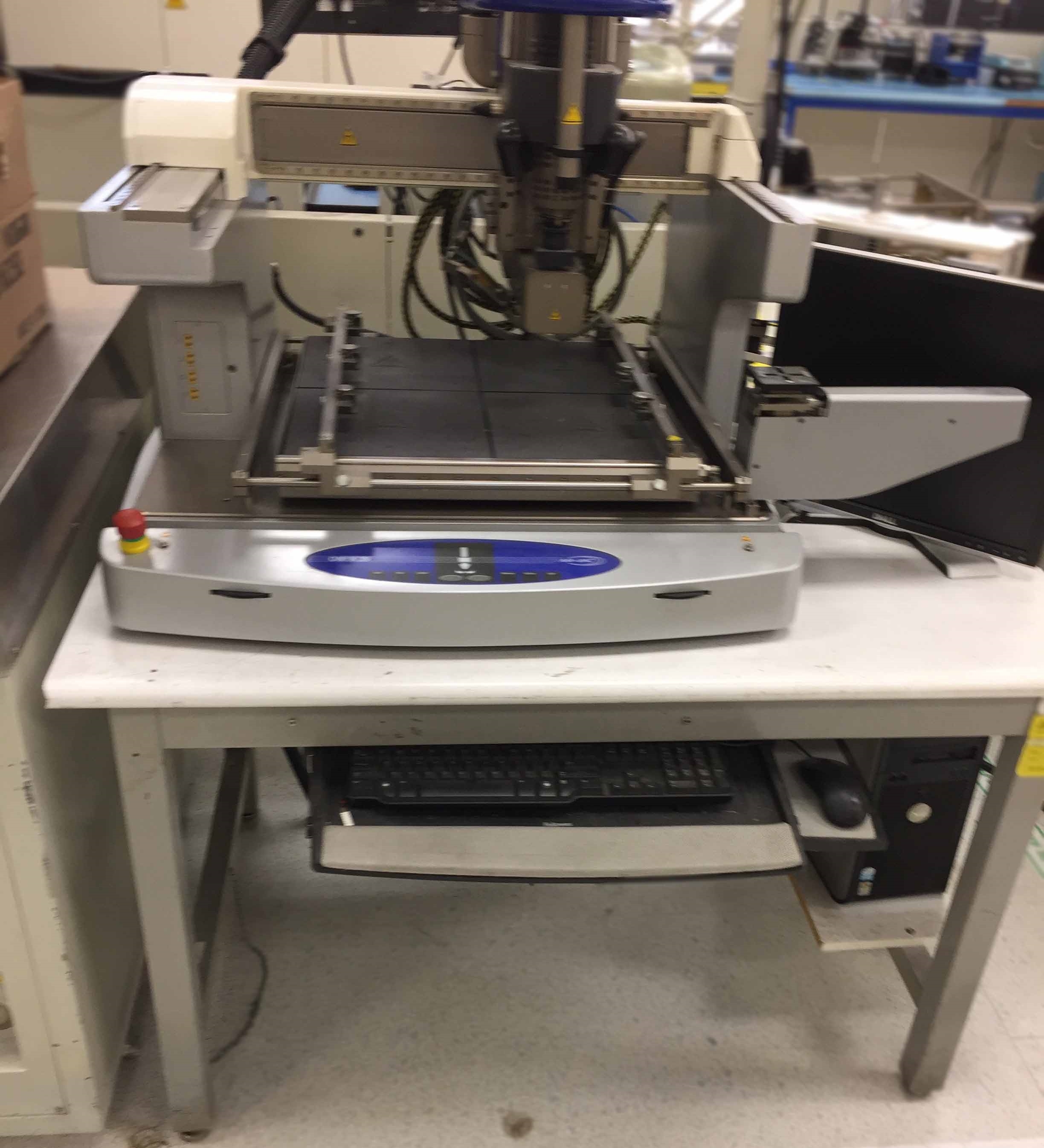

Used AIRVAC / ZEVAC Onyx 29 #9210110 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9210110

Vintage: 2006

BGA Rework station

2000 Watts top heater (9 x 19 inch)

5600 Watts four zone pre-heater

Computer control mini server

Ultra-fast heat up for lead-free compatible

Direct view camera

X-Y Table alignment with laser point

Board size maximum support: 20.0"W x unlimited

Temperature IR sensor with laser pointer

2006 vintage.

AIRVAC / ZEVAC Onyx 29 is a state of the art pc board assembly and manufacturing equipment utilizing Onyx software and Panasonic's NPM series of pick and place machines. The system is capable of efficiently assembling, testing, and manufacturing high quality Printed Circuit Board assemblies with speeds up to 8,700 CPH (Components Per Hour). ZEVAC Onyx 29 unit is designed to handle all types of PCBs, from single-sided to eight-layer double-sided boards, and with an accuracy of ± 0.1mm. It also has a variety of feeder types, allowing the use of reel, tube, and tray feeders, as well as the ability to handle all components from 0402 to large leaded components. The NPM series ofpick and place machines are capable of reliably placing 0201 components and up to 66.2 mm large components with speeds ranging from 8,700 CPH for high volume jobs to 4,500 CPH for low part count or specialty jobs. AIRVAC Onyx 29 machine features a state of the art software tool, utilizing LEAN concepts of data collection, analysis and control. The asset allows the operator to control all aspects of the assembly process, from parts selection and placement, to verification and fault diagnosis. The model has several built-in self-diagnostics features that detect faults and failures before they can occur and provide the operator with an early warning of potential component or process related problems. Additionally, the equipment offers a library of reusable components, which helps operators quickly reconfigure jobs with commonly used parts and, as a result, increases First-pass Yield and Quality. Onyx 29 system is also capable of providing high-speed component testing and rework. It features an AOI (Automatic Optical Inspection) unit, which automatically checks assembled PCBs for any faults, allowing a rapid response to problems and optimizing production efficiency. The machine also offers advanced options, allowing the operator to rework and/or replace defective components without having to unsolder or manually remove the original components. This allows for a faster rework process, reduces the overall time to repair and increases the life of the components being replaced. In addition to AIRVAC / ZEVAC Onyx 29 PLM tool, ZEVAC also offers a variety of additional services, such as pre-programming, pre-testing, and test certification. This allows customers to ensure their PCBs are ready to use and help prevent any unwanted delays in production. Overall, ZEVAC Onyx 29 is a highly powerful and efficient solution for PCB assembly and manufacturing, providing the customer with high-speed production with advanced features and excellent quality. With its advanced diagnostic asset and additional services, AIRVAC Onyx 29 is the ideal solution for any production environment.

There are no reviews yet