Used AIRVAC / ZEVAC PCBRM-10 #175364 for sale

URL successfully copied!

Tap to zoom

ID: 175364

Soldering and rework station

Unit has a 2599 watt heater, goes to about 620°F (sufficient for no-lead operations).

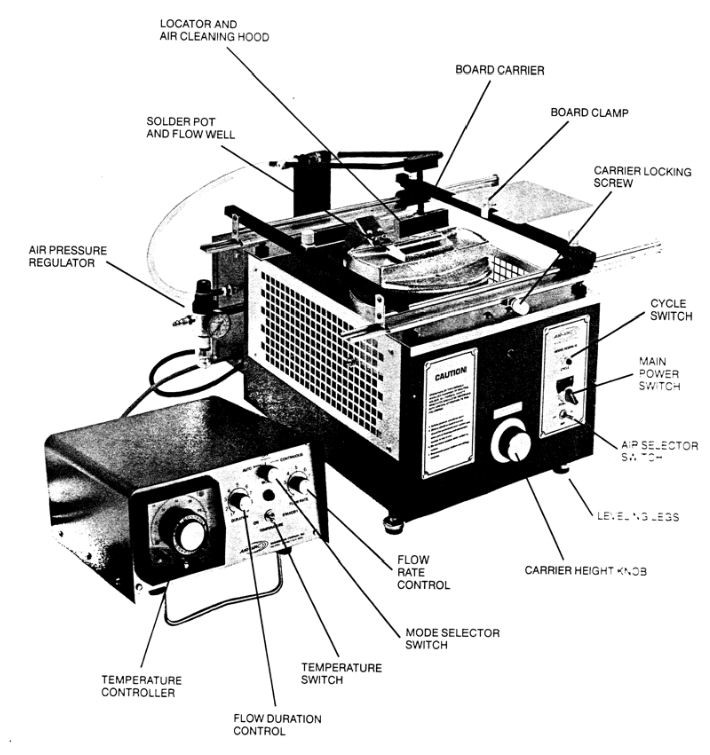

AIRVAC / ZEVAC PCBRM-10 equipment offers a comprehensive, cost-effective solution for PC board assembly and manufacturing. This system automates the process of placing SMD components onto a PCB and soldering them together in a single pass, for quicker, more accurate results. The unit includes a variety of components, such as the automated sliding conveyor, soldering paste applicator arm, card presence detector, solder flux unit, board verification station and card indexer. The conveyor produces an adjustable, high-speed motion that can transport PC boards and their components between individual stations. The soldering paste applicator arm adds controlled amounts of soldering paste onto each component pad surface, to ensure greater accuracy and reliability. The card presence detector checks the movement of each component to ensure it is in the right position upon the board. The solder flux unit is used to activate the flux paste for better adhesion and wetting of the solder. The board verification station verifies the boards for exact component placement and automated visual inspection. Last, but not least, the card indexer module reads a board's data and aligns it properly on the conveyor for soldering. All components of ZEVAC PCBRM-10 machine are manually adjustable to adapt to the requirements of each customer. This includes the size and placement of components, soldering paste application, flux paste selection and temperature settings, as well as speed and alignment of the conveyor tool. Additionally, the asset is easy to use and safe to operate, with high-level accuracy and repeatability being maintained. It also allows for flexible programming and easy parameter changes, giving users greater flexibility and control over the manufacturing process. Overall, AIRVAC PCBRM-10 model is a reliable and effective solution for PC board assembly and manufacturing. It offers greater accuracy, improved throughput, and cost reduction, while also providing higher flexibility and control. The equipment is an ideal choice for high-volume production, as it provides an efficient, cost-effective manufacturing process.

There are no reviews yet