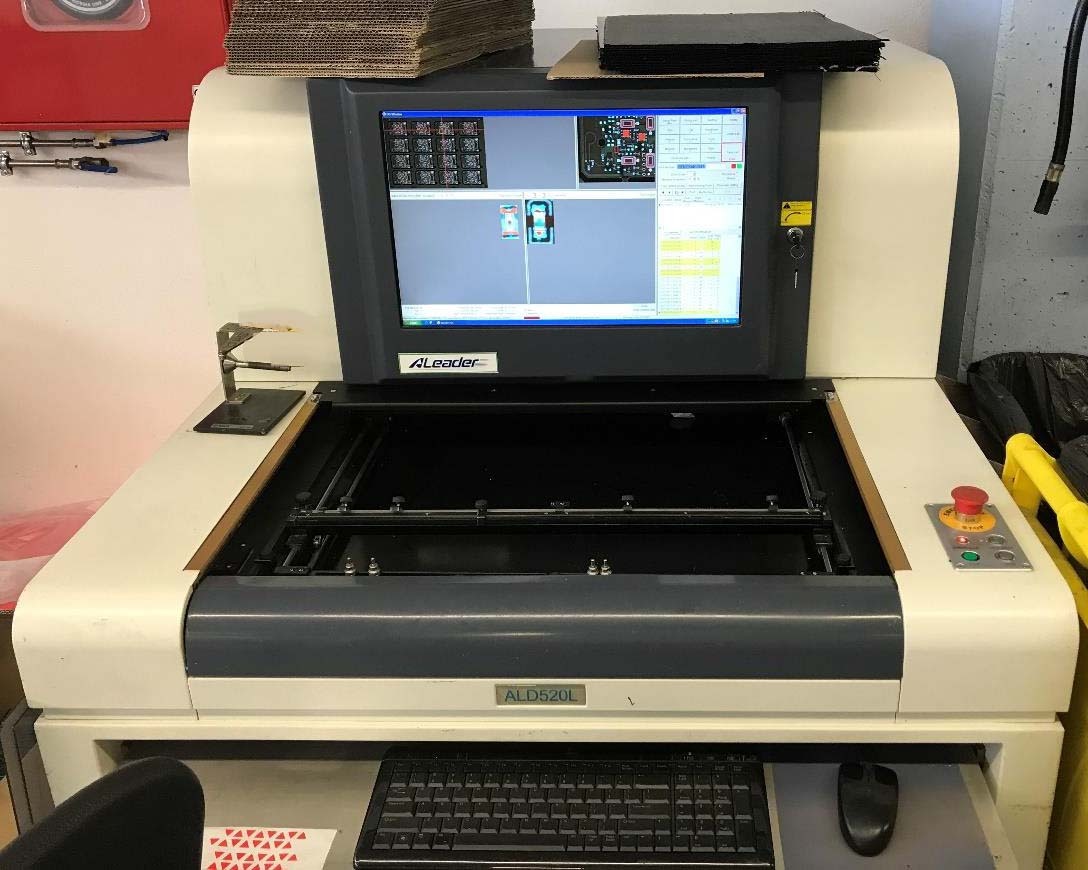

Used ALEADER VISION TECHNOLOGY ALD520L #9187091 for sale

URL successfully copied!

Tap to zoom

ALEADER VISION TECHNOLOGY ALD520L is an industry leading PC Board Assembly and Manufacturing equipment designed specifically for PCB assembly and manufacturing processes. This system is primarily used in the fields of consumer electronics, industrial control equipment, automotive components, and medical devices. ALD520L features a cost-efficient, reliable, and integrated vision-guided PC Board Inspection Unit that is designed to improve productivity and accuracy of today's most sophisticated PCB assembly and manufacturing plants. Utilizing the precise line-scan cameras, the machine can detect and inspect PCBs with a superior level of accuracy and repeatability. The inspection tool uses exposure-level protection to control exposure levels and prevent damage to delicate PCB components during inspection. ALEADER VISION TECHNOLOGY ALD520L asset also includes an advanced auto-focus feature that detects board components down to finer details with precise image recognition. This precise image recognition is crucial in accurately detecting even the smallest variances at various levels of inspection. This is one of the most important features of ALD520L model as it enables maximum accuracy and repeatability when inspecting PC boards. ALEADER VISION TECHNOLOGY ALD520L also features an embedded vision programming equipment that facilitates easy integration with the various PC Board Manufacturing Automation systems used in the industry. This integration allows for intelligent communication between the automation system and the vision unit for fast, accurate operation. Additionally, ALD520L includes a wide variety of software packages that are designed to simplify programming, maximize testing coverage, and ensure that the results are obtained correctly. The optional Desktop software package allows for even easier programming and data debugging. ALEADER VISION TECHNOLOGY ALD520L is ideal for high-volume manufacturing due to its superior accuracy, repeatability, and fast operation. Its PC board inspection and manufacturing software are designed to provide maximum efficiency and reliability on the production line. Additionally, its versatile interface offers consistent integration with existing automation systems, making it an important tool for PCB assembly and manufacturing.

There are no reviews yet