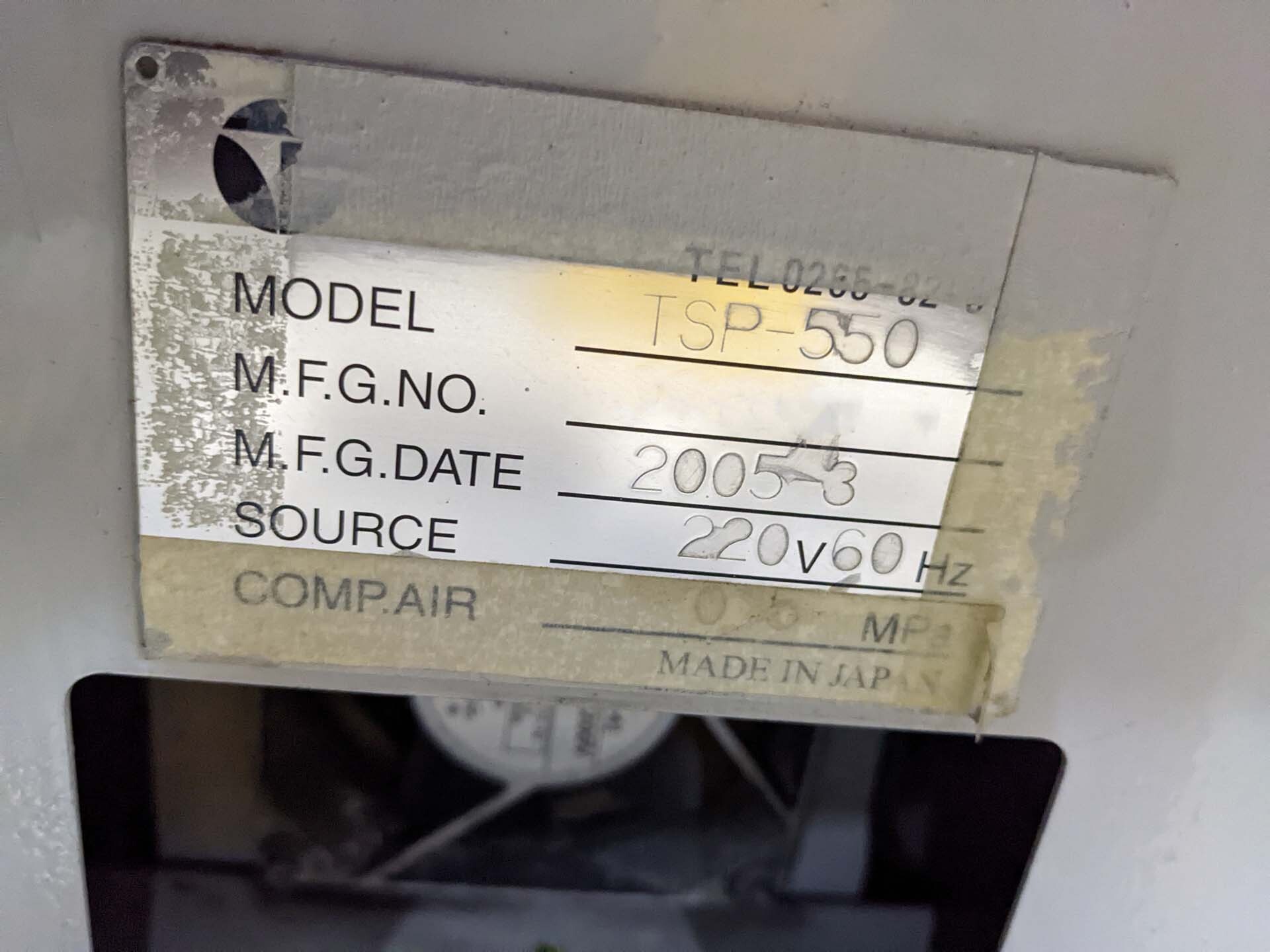

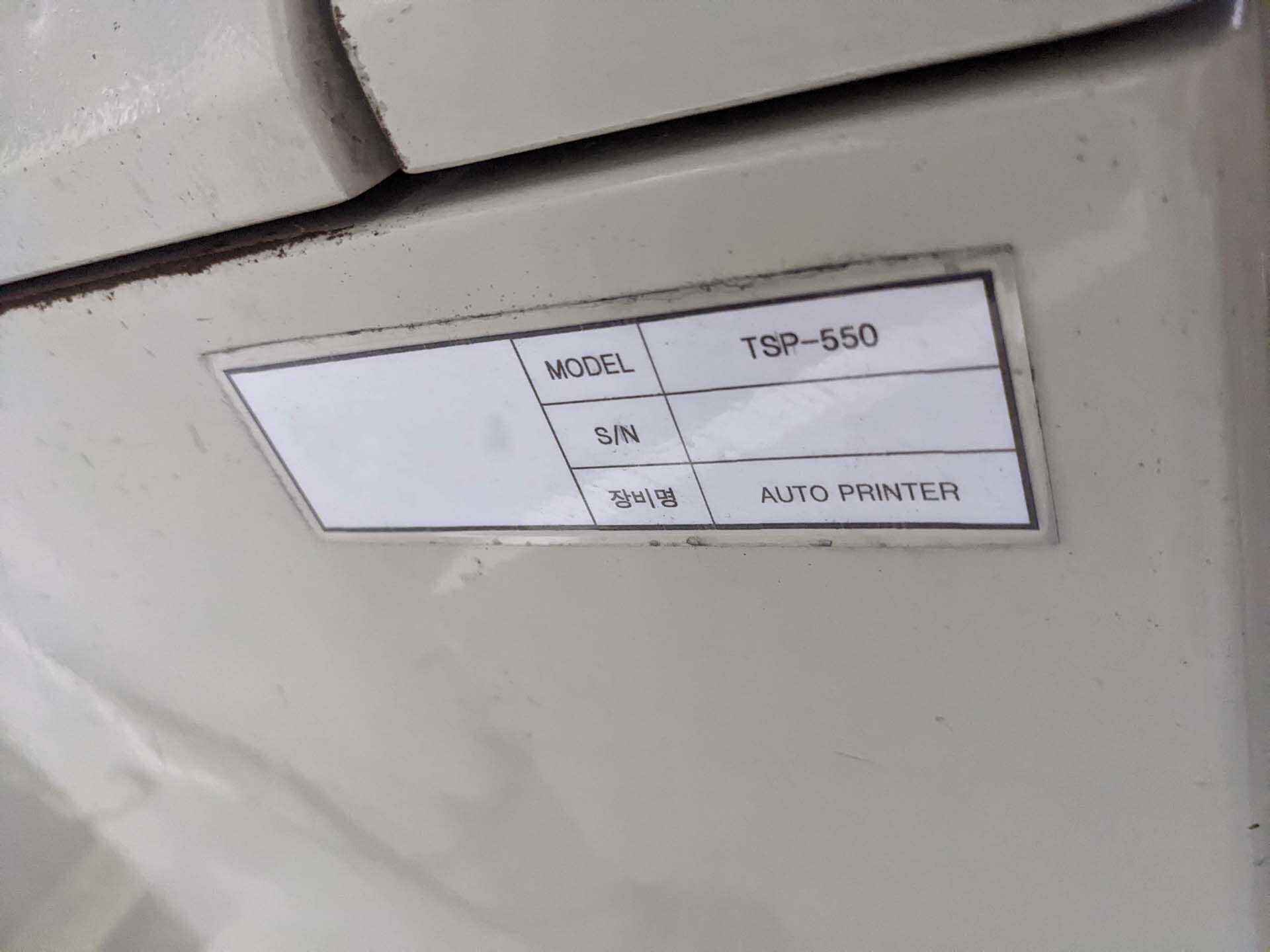

Used AMISTAR / TENRYU TSP550 #293631671 for sale

URL successfully copied!

Tap to zoom

AMISTAR / TENRYU TSP550 is a PC board assembly and manufacturing equipment from Toshiba Machine Co., Ltd. It is a highly advanced system for producing high-quality single side, double-sided, and multilayer printed circuit boards (PCBs). It employs the latest in precision mechanical, electronic, and optical technology to ensure that complex boards can be manufactured efficiently and with a high level of accuracy and reliability. TENRYU TSP550 uses an integrated vision unit with a powerful image processing and an optical double-sided inspection machine (ODIS) to accurately acquire more than 400 different types of images throughout the manufacturing process, which can be used to detect abnormalities in the surface structure, components, and terminals of a printed circuit board. This functions with a precision of 0.2mm tolerance. AMISTAR TSP550 is designed for easy assembly, with a fast and easy-to-use automated surface mounter. This machine has a wide range of functions and force settings, making it quick and simple to mount components. It is capable of mounting 0.3mm size chips, 12mm long leads, and components with a maximum height of 4mm. It also supports marking on various types of components. The tool is also a highly efficient asset for prototyping, using the supplied surface mounter and reflow oven to reduce the production time for prototypes. TSP550 can also be used for high-volume production runs. The model also has a built-in robot arm for placing parts, which helps reduce human error and makes the equipment safer for operators. It can be operated in either manual or automatic mode, helping to make the production process more cost-effective and precise. The system is also designed with safety features such as emergency stop buttons and automatic light curtains. AMISTAR / TENRYU TSP550 is designed to provide the highest levels of reliability and quality, making it the ideal choice for high-precision PCB assembly and manufacturing. It is suitable for a variety of applications and offers advanced features such as real-time monitoring and image recognition, to help meet the needs of customers. It is also one of the fastest systems on the market, completing a full single-sided PCB in only 8-10 seconds.

There are no reviews yet