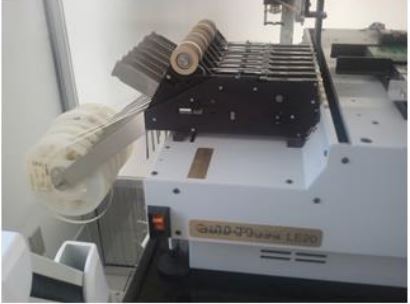

Used APS / AUTOMATED PRODUCTION SYSTEMS Gold Place LE 20 #9133117 for sale

URL successfully copied!

Tap to zoom

APS / AUTOMATED PRODUCTION SYSTEMS Gold Place LE 20 is a pc board assembly and manufacturing equipment developed by APS. The main purpose of this system is to provide high-quality and fast assembly and manufacturing of circuit boards using advanced automated processes, tools and systems. APS Gold Place LE 20 is a comprehensive unit that consists of several components, including an automated placement machine, a bill-of-materials tracking software, a fully-automated solderer, electrical test systems, and a wide range of material handling systems. The automated placement machine is the heart of the machine, as it is responsible for accurately and quickly placing components on the PCB (Printed Circuit Board). The bill-of-materials tracking software is used to keep track of parts and components used in the assembly process, as well as to maintain detailed data on the overall production process. The fully-automated solderer is used to solder components to the PCB, while the electrical test systems are used to ensure all parts and components are working properly after the assembly process. Lastly, the material handling systems provide a quick and efficient way to move parts and components around the assembly floor. AUTOMATED PRODUCTION SYSTEMS Gold Place LE 20 is designed to be user-friendly, as the tool can be operated by a single operator or a group of operators. It also features a clean and tidy layout to reduce waste and the need for manual labour. Additionally, the asset provides detailed production tracking and statistical reports, enabling operators to measure and analyse performance with accurate data and reporting. The model is also designed to be highly efficient, as it can complete a board assembly in a significantly shorter time than with traditional manual assembly processes. Overall, Gold Place LE 20 is a reliable and user-friendly pc board assembly and manufacturing equipment that can provide high-quality production with quick and efficient automated processes. The system can help to minimize the need for manual labour, increase production speeds and reduce costs associated with assembly and manufacturing. Additionally, detailed production tracking and reports enable operators to consistently monitor and optimize the production process for optimum quality and efficiency.

There are no reviews yet