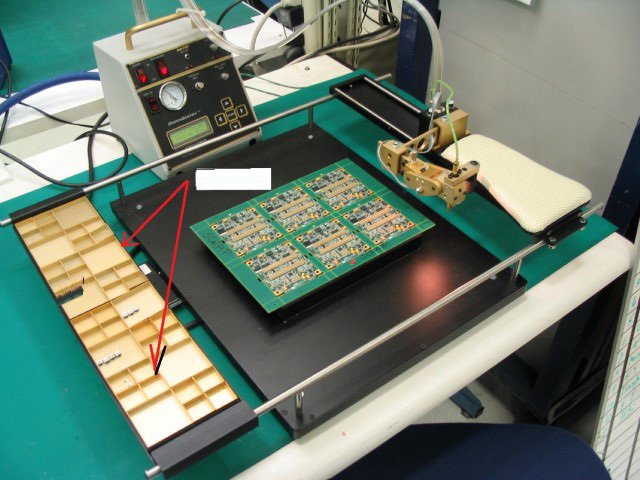

Used APS / AUTOMATED PRODUCTION SYSTEMS Novastar MPP-11 #9041751 for sale

URL successfully copied!

Tap to zoom

ID: 9041751

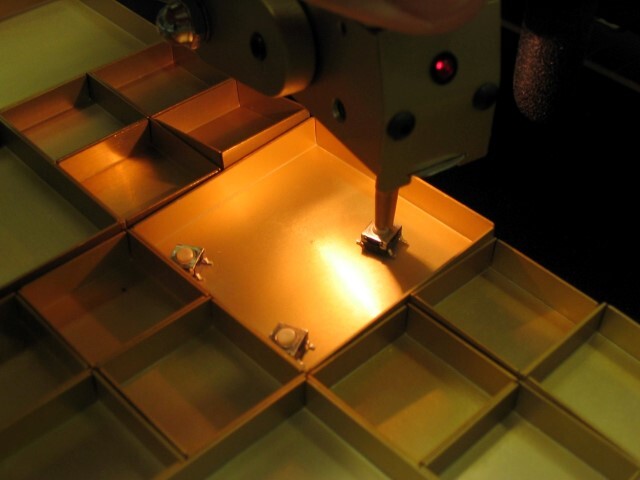

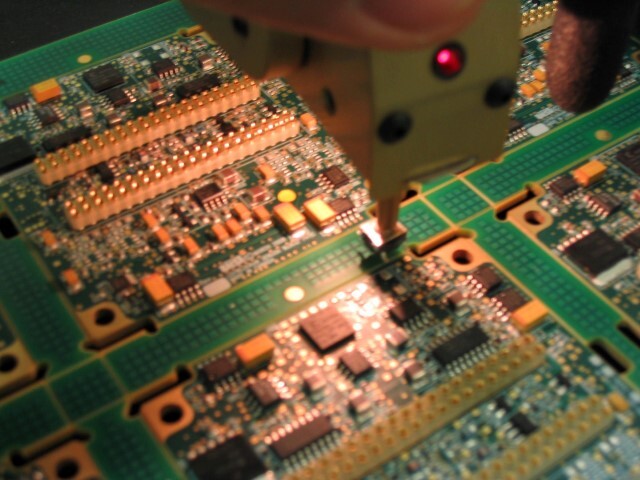

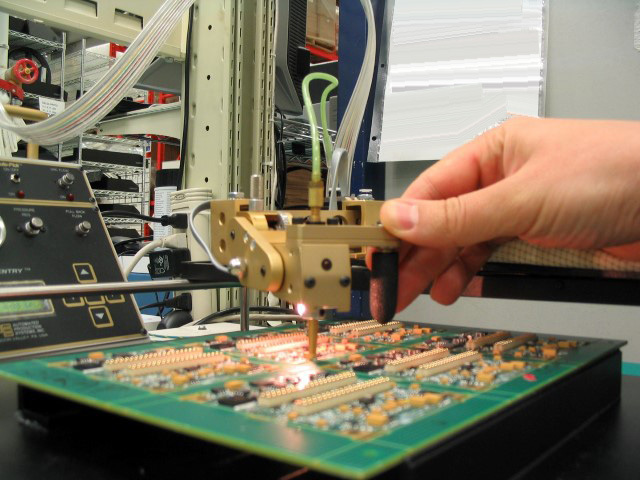

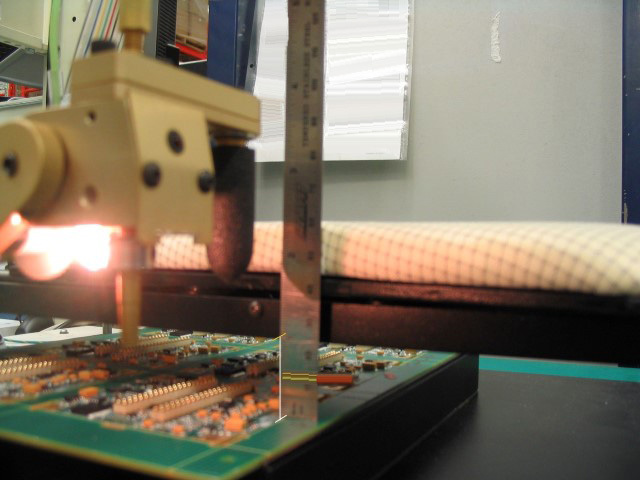

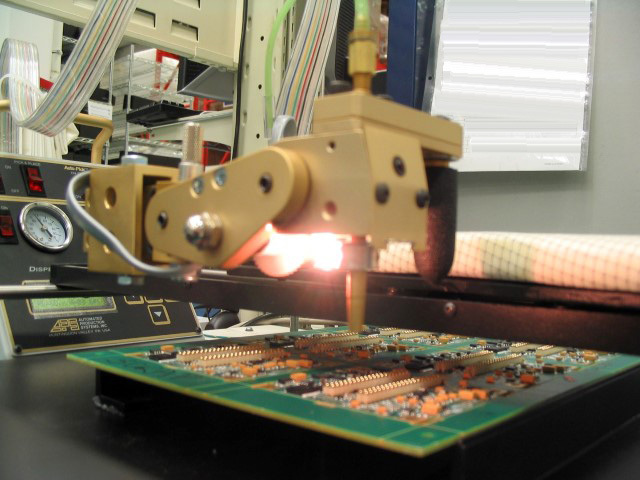

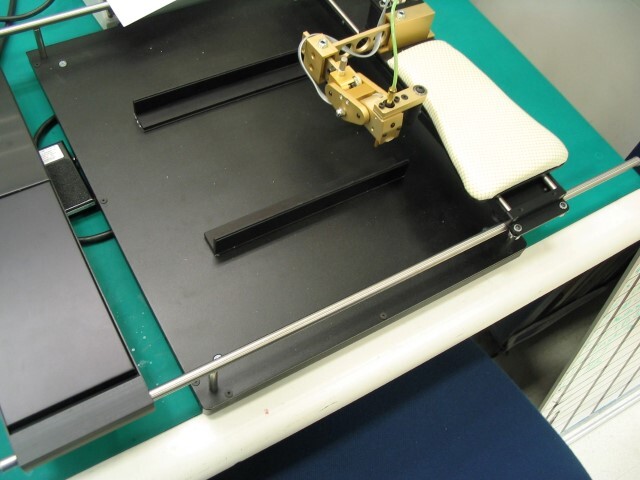

Manual pick and place machine

4-Mode programmable dispenser

Benchtop

Power: 120/240VAC, 50/60Hz, 1amp

Shop air: 100psi max

Slide-line connector kit option: no

Currently not in use

2011 vintage.

APS / AUTOMATED PRODUCTION SYSTEMS Novastar MPP-11 is a computer board assembly and manufacturing equipment designed to automate the production of printed circuit boards (PCBs) and their associated electrical and mechanical components. The system utilizes computer numerical control (CNC) technology to program machines, providing accuracy and speed of PCB production. The MPP-11 unit consists of a series of automated mechanical and electrical functions. The main component is the mechanical platform on which the PCB is constructed. This platform consists of several modules, each designed to individually perform specific manufacturing operations. The first module is the pick-and-place module, which is responsible for loading and unloading the components that are to be placed on the PCB. This module consists of an automated axis that is used to select and position the components before they are placed onto the PCB. The next module is the solder reflow module which is responsible for connecting the components together with a soldering process. This module uses a hot plate with a variety of heat settings to bond the components to the PCB. The third module is the die attach or wire bond module, which is responsible for physically attaching the components to the PCB. This module utilizes a variety of methods depending on the type of component being attached. This process can include soldering, crimping or pin welding. Once these processes have been completed, the assembly moves to the final module which is the test module. This module is responsible for ensuring that the components and connections have been correctly made and are operating as expected. This is carried out using various tests such as continuity, voltage and current measurements. The entire machine operates under the control of a Programmable Logic Controller (PLC), which is responsible for controlling the individual operations of each module. This PLC is programmed to automatically start and stop specific operations, as well as adjust the parameters specific to each manufacturing operation. The PLC is also responsible for monitoring the tool, providing information such as the status of the asset and operations and error logging. Overall, APS Novastar MPP-11 is a highly efficient automated production model designed to quickly and accurately manufacture PCBs and their associated components without the need for manual labor. Its combination of precision CNC technology, automated Pick and Place operations, Solder Reflow and Die-Attach processes, and Test Module capabilities make it an ideal choice for automated PCB production.

There are no reviews yet