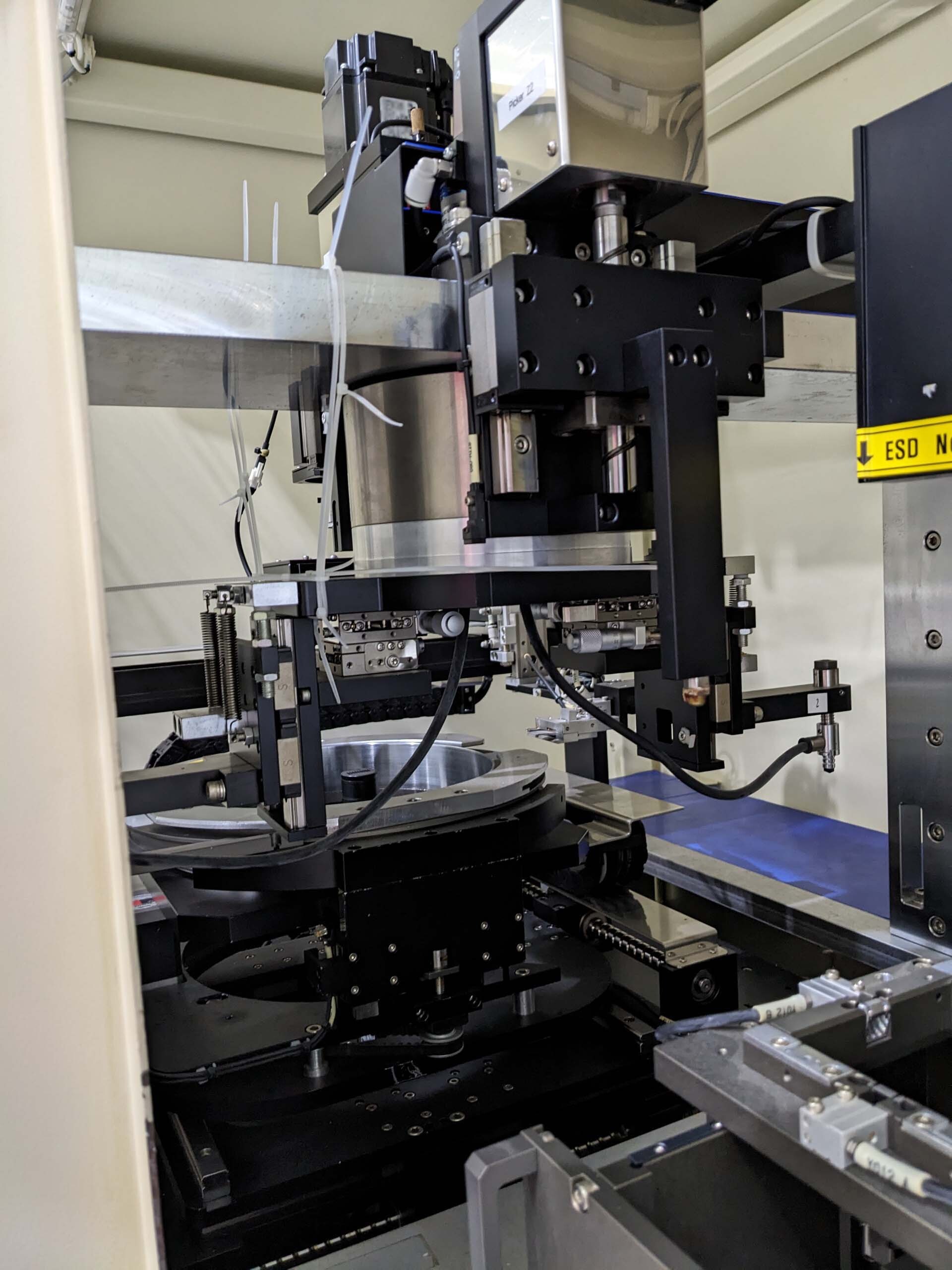

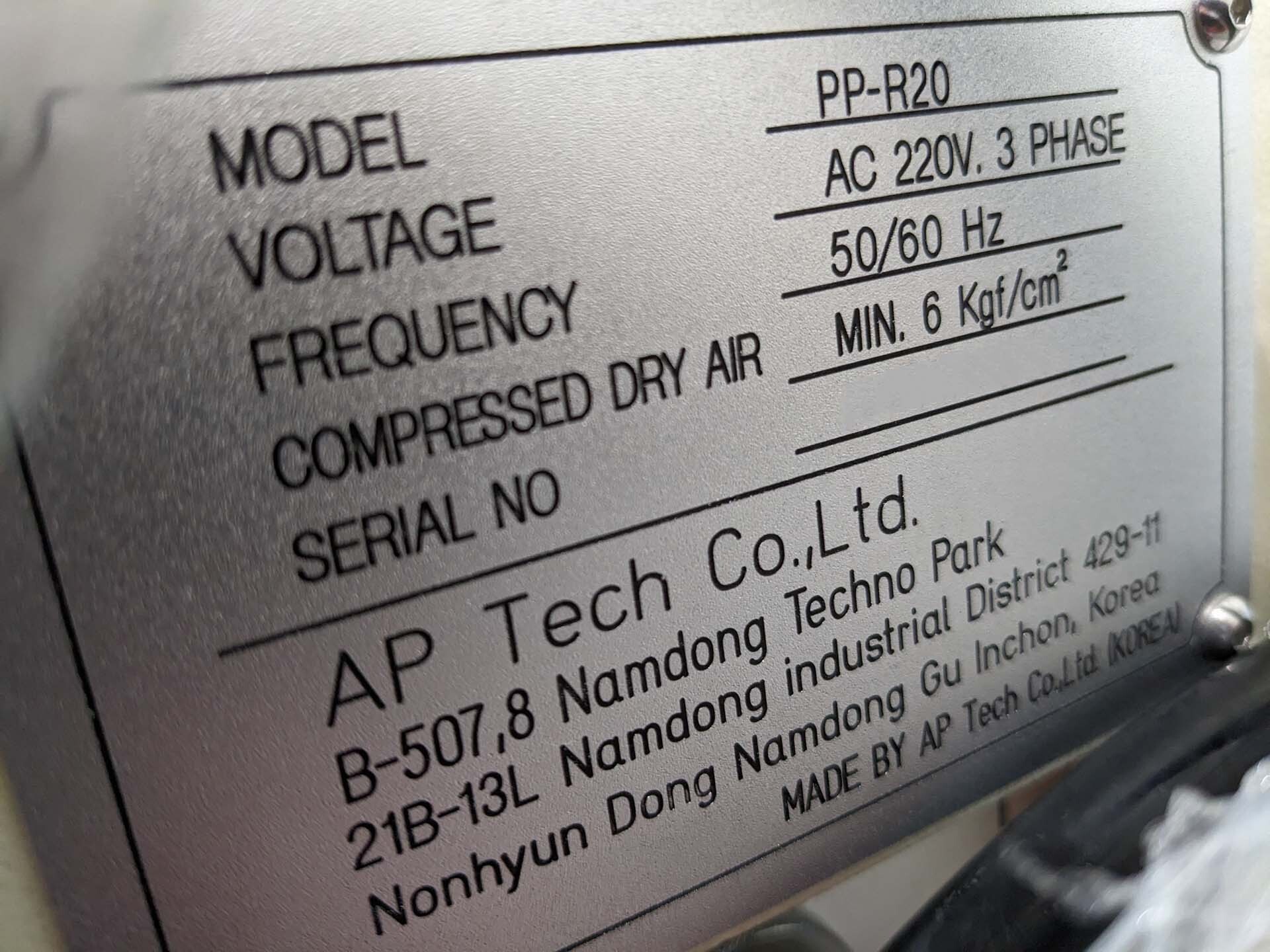

Used APTECH PP-R20 #9378404 for sale

URL successfully copied!

Tap to zoom

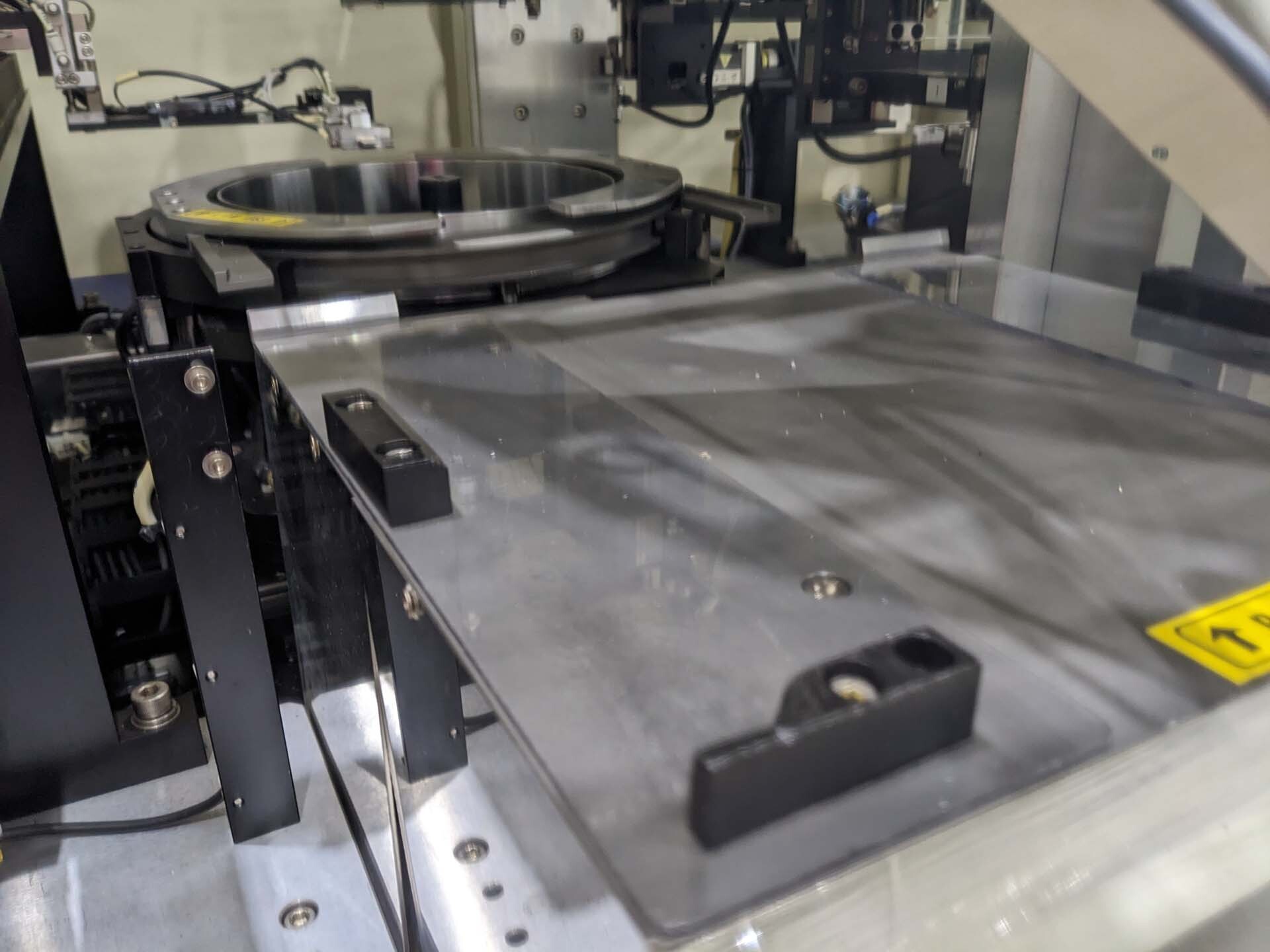

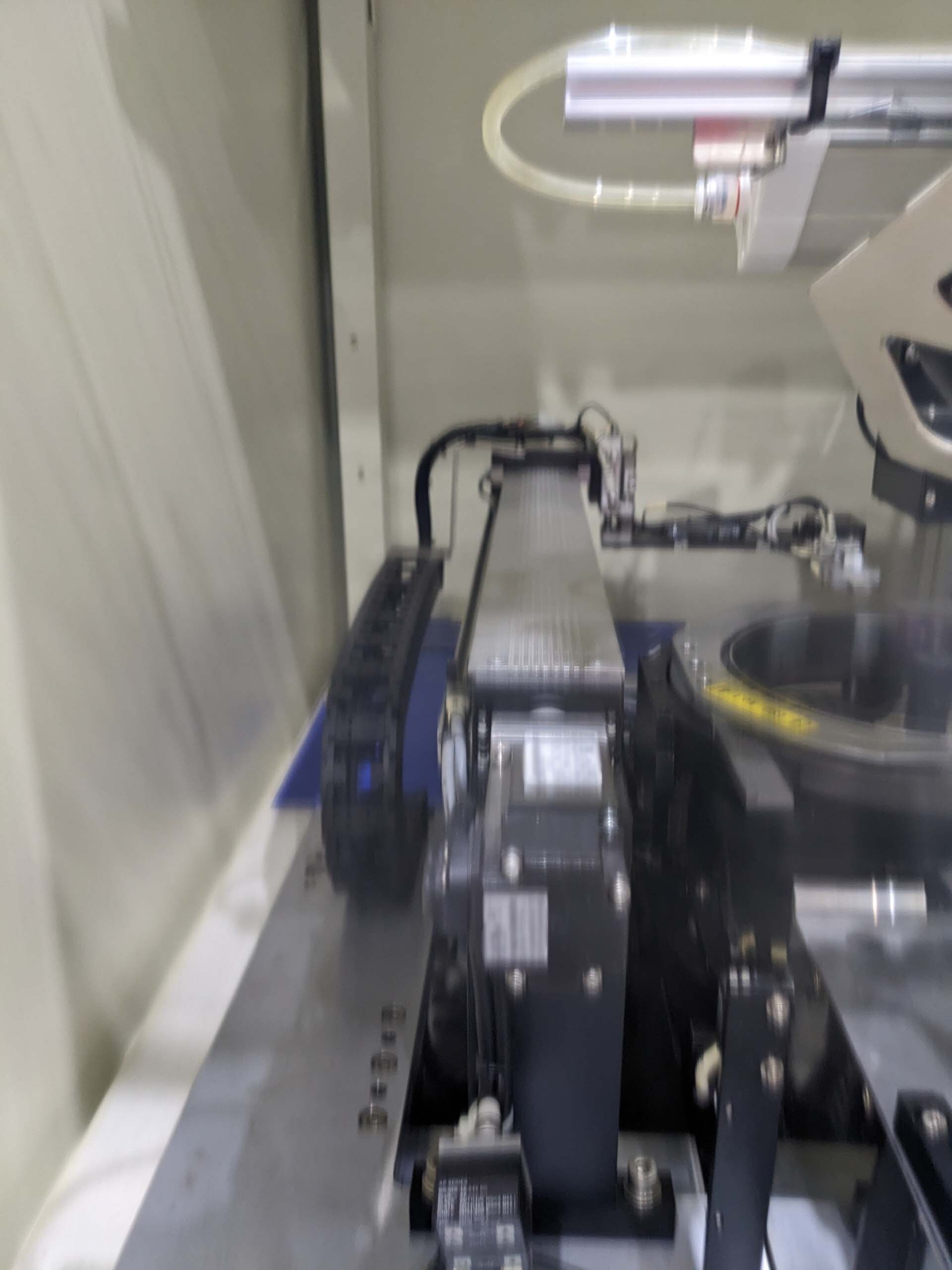

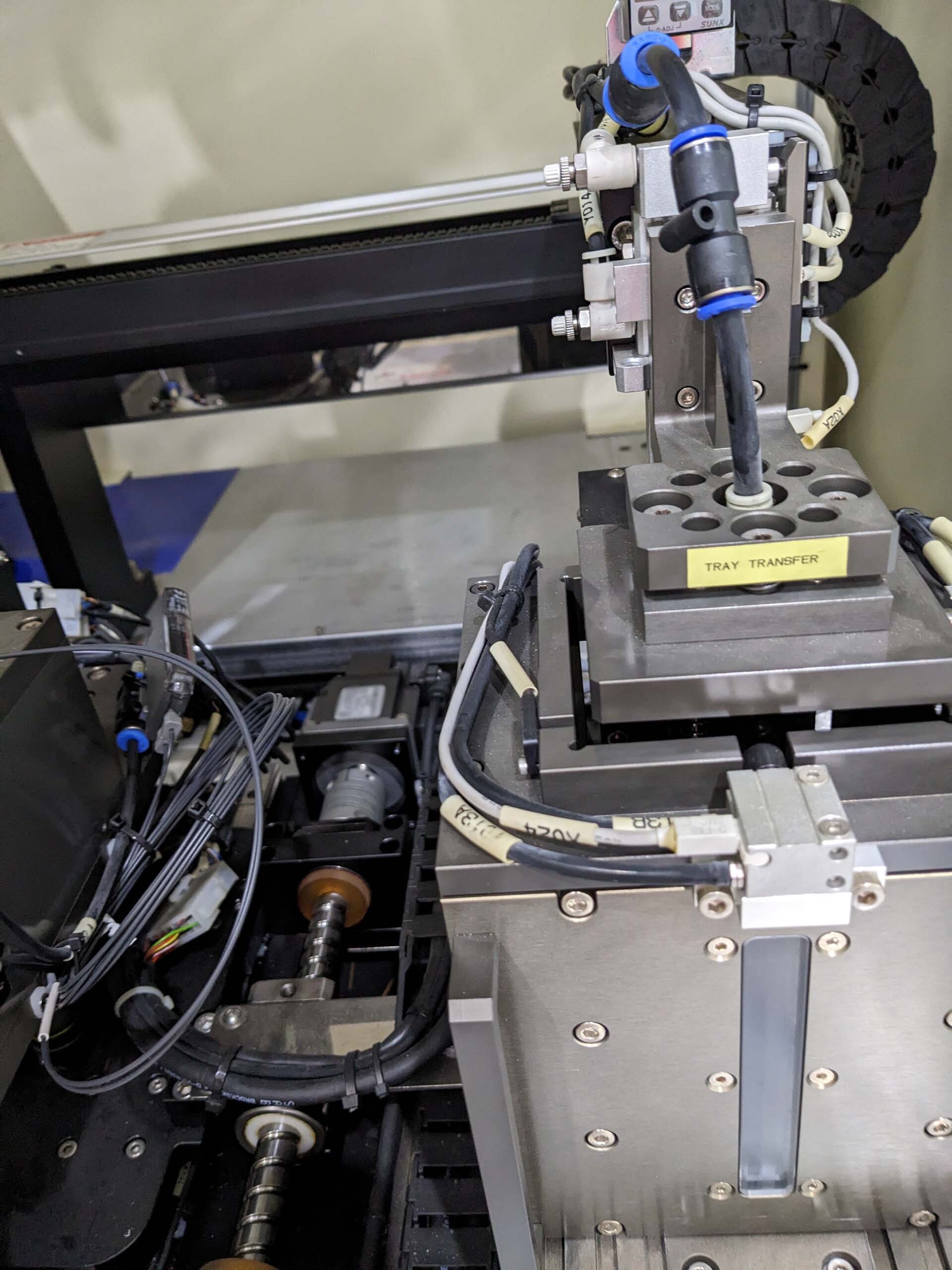

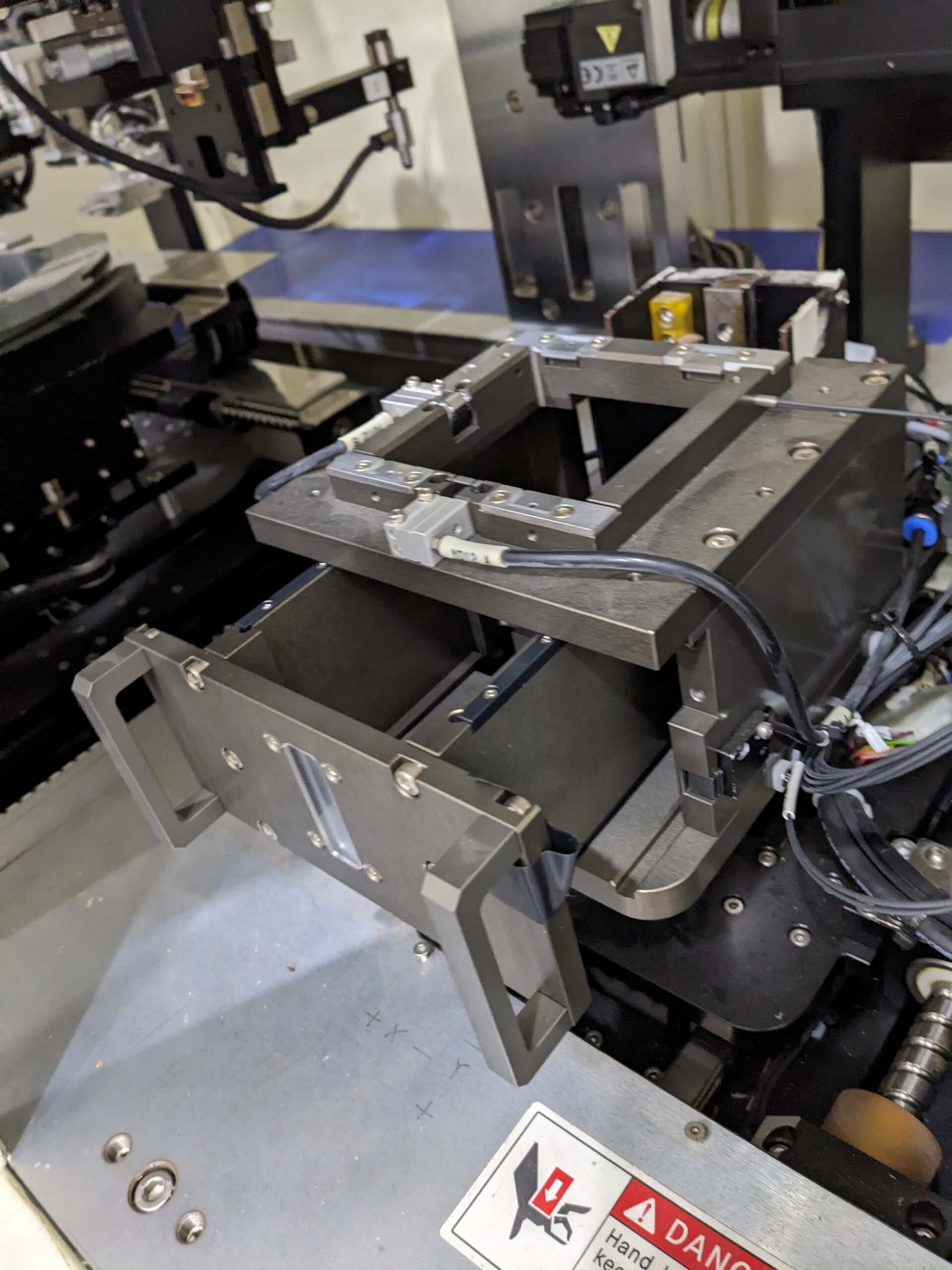

APTECH PP-R20 is a pc board assembly and manufacturing equipment specifically designed to meet the stringent requirements of the manufacturing industry. It is an ideal solution for any organization requiring high-volume production and perfect surface mount technology (SMT) assembly. PP-R20 is capable of assembling SMT components on boards up to 3.3 inches thick and is constructed using high-precision, easy-to-use components. It is capable of supporting double- and single-sided SMT assembly, and is fully compliant with RoHS and IPC standards for printing and soldering. APTECH PP-R20 boasts a collection of innovative features such as a high-precision board handling system and an advanced feeder unit. Its user-friendly, plug-and-play design makes it simple to set up and use. The board handler allows user to quickly move printed circuit boards (PCBs) to the loading and unloading station, with no additional setup. The feeder machine is optimized to provide accurate and consistent components placement, even at high throughputs. PP-R20 is also equipped with a number of safety features such as locked doors, audible warning devices, and a powerful pneumatically driven eject tool for emergency stoppage. It has the capability to store up to 500 programmable job settings for quick job changes. Additionally, it has an onboard data logging asset to monitor model performance and for future troubleshooting. Finally, APTECH PP-R20 is designed for easy maintenance. Maintenance kits, training support, and manual are all included for operators to quickly access in the event of an emergency or issue. With its robust design, it provides reliable and dependable operation for demanding and challenging production environments.

There are no reviews yet