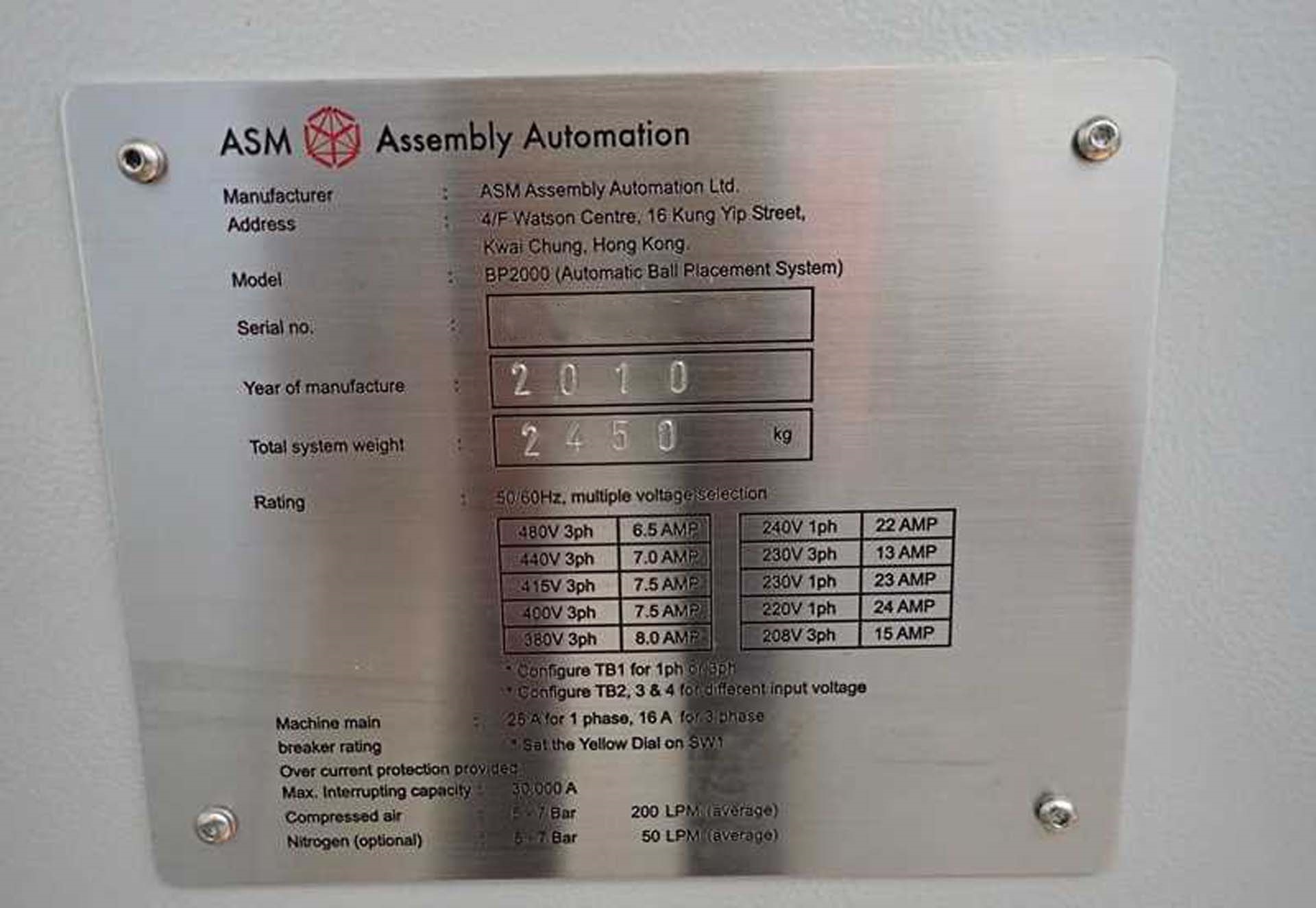

Used ASM BP 2000 #9245315 for sale

URL successfully copied!

Tap to zoom

ID: 9245315

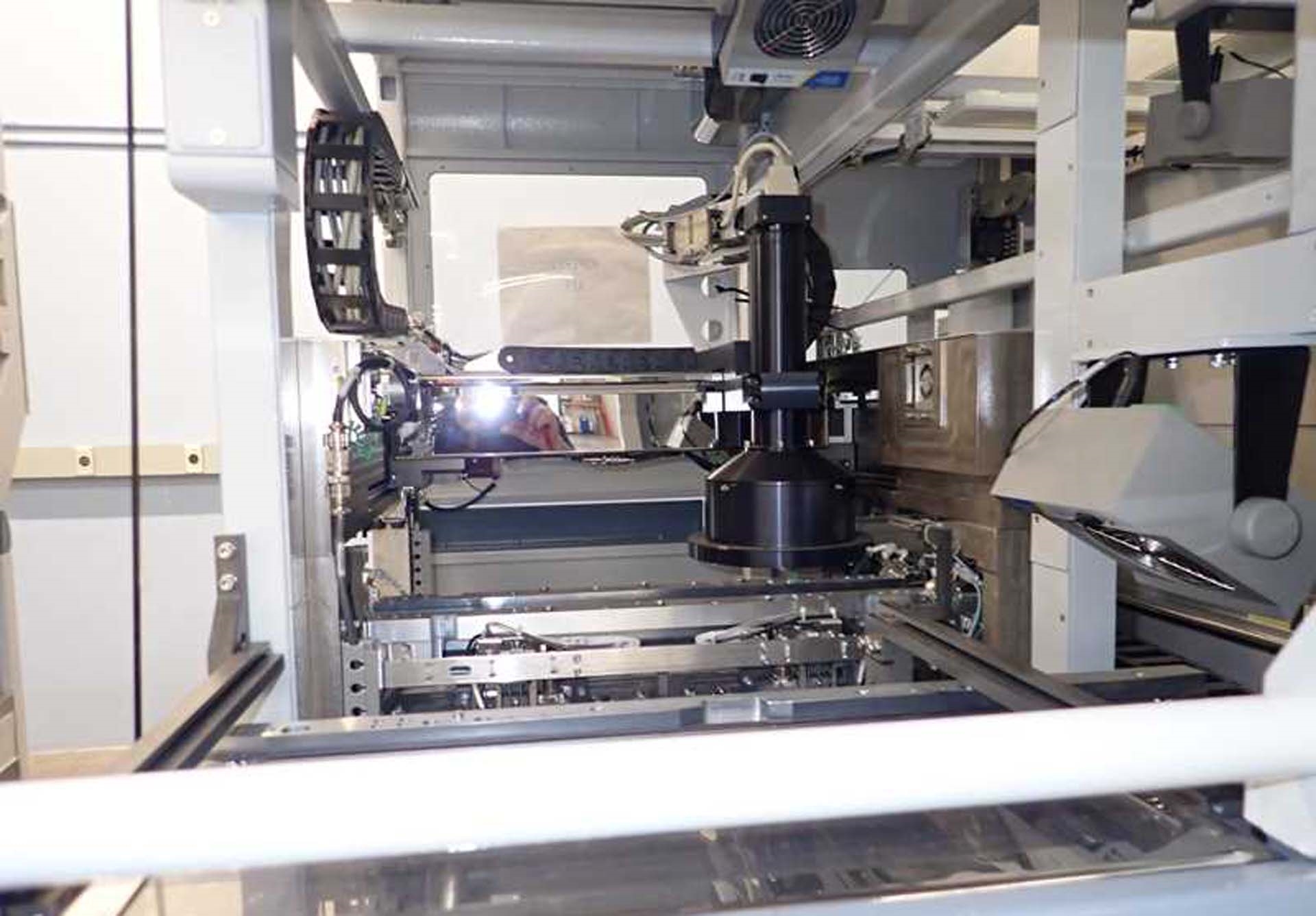

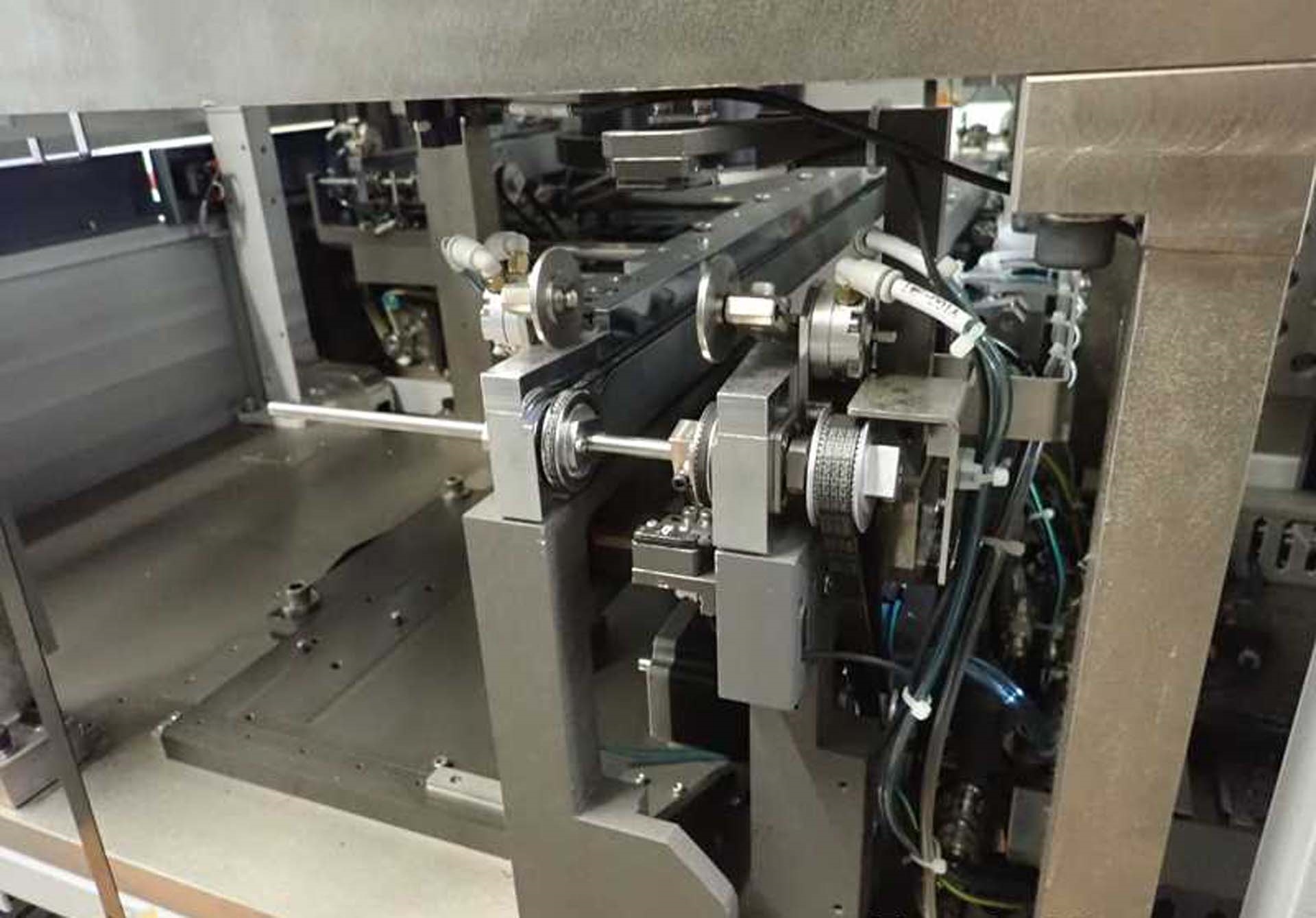

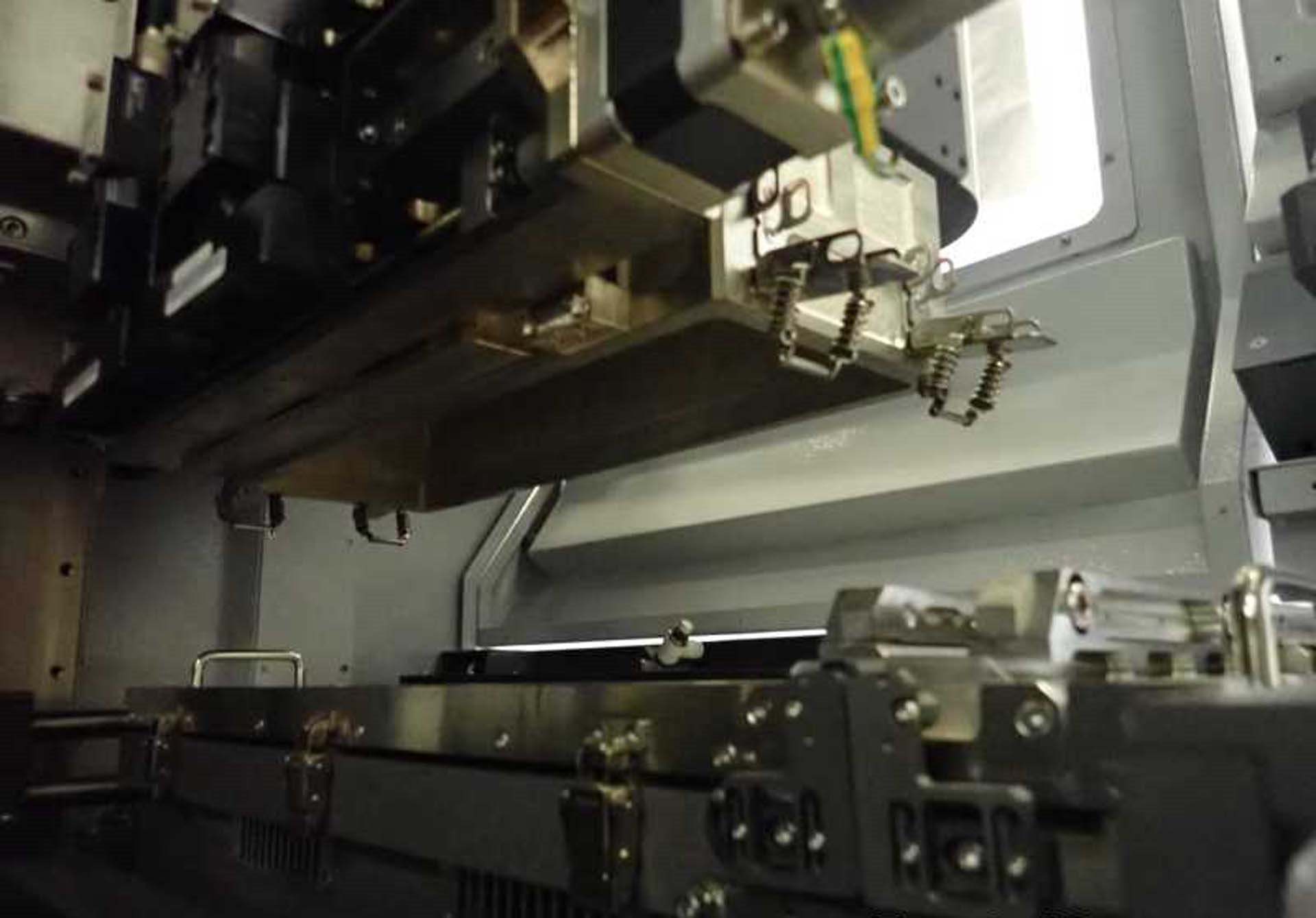

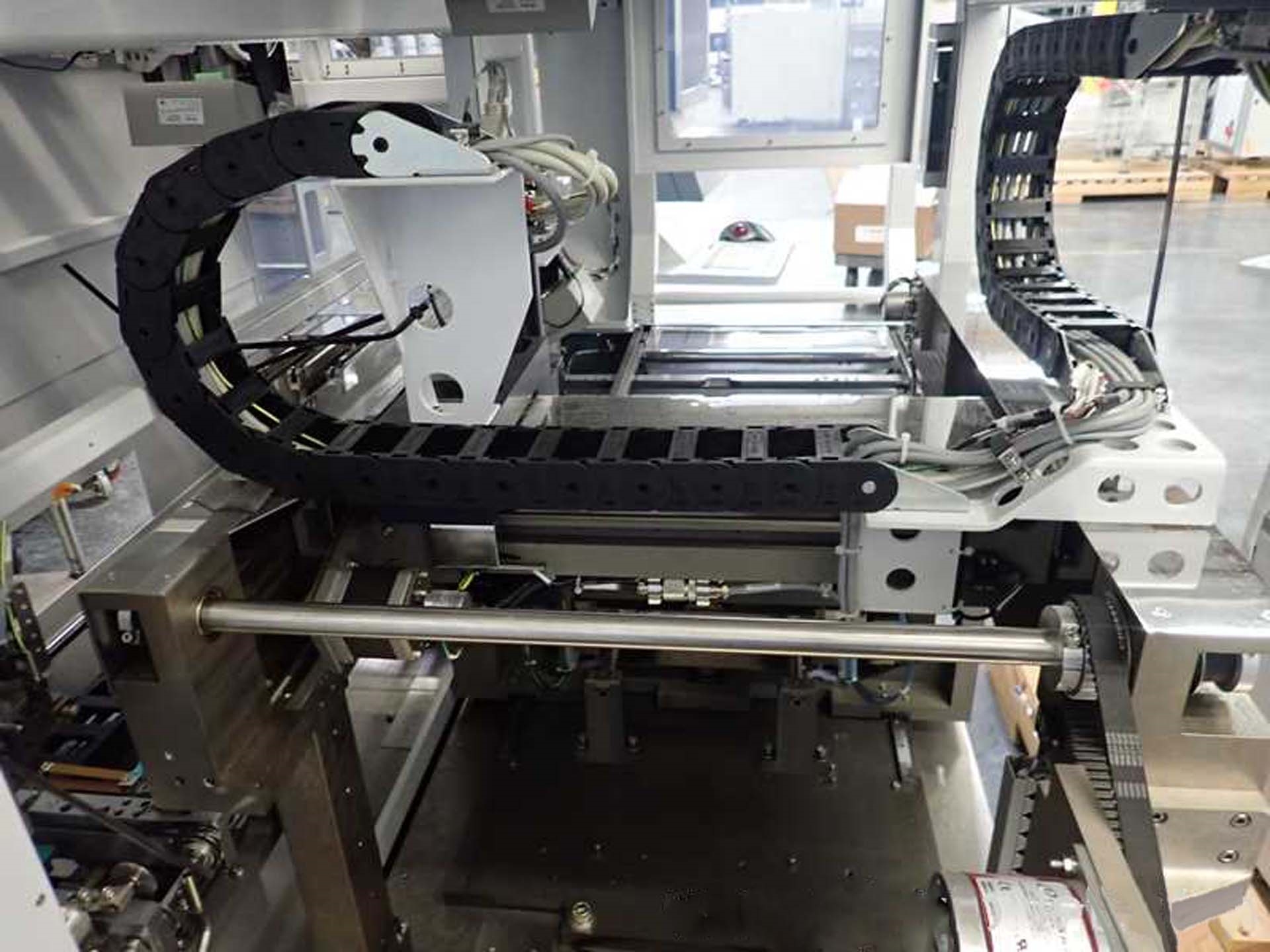

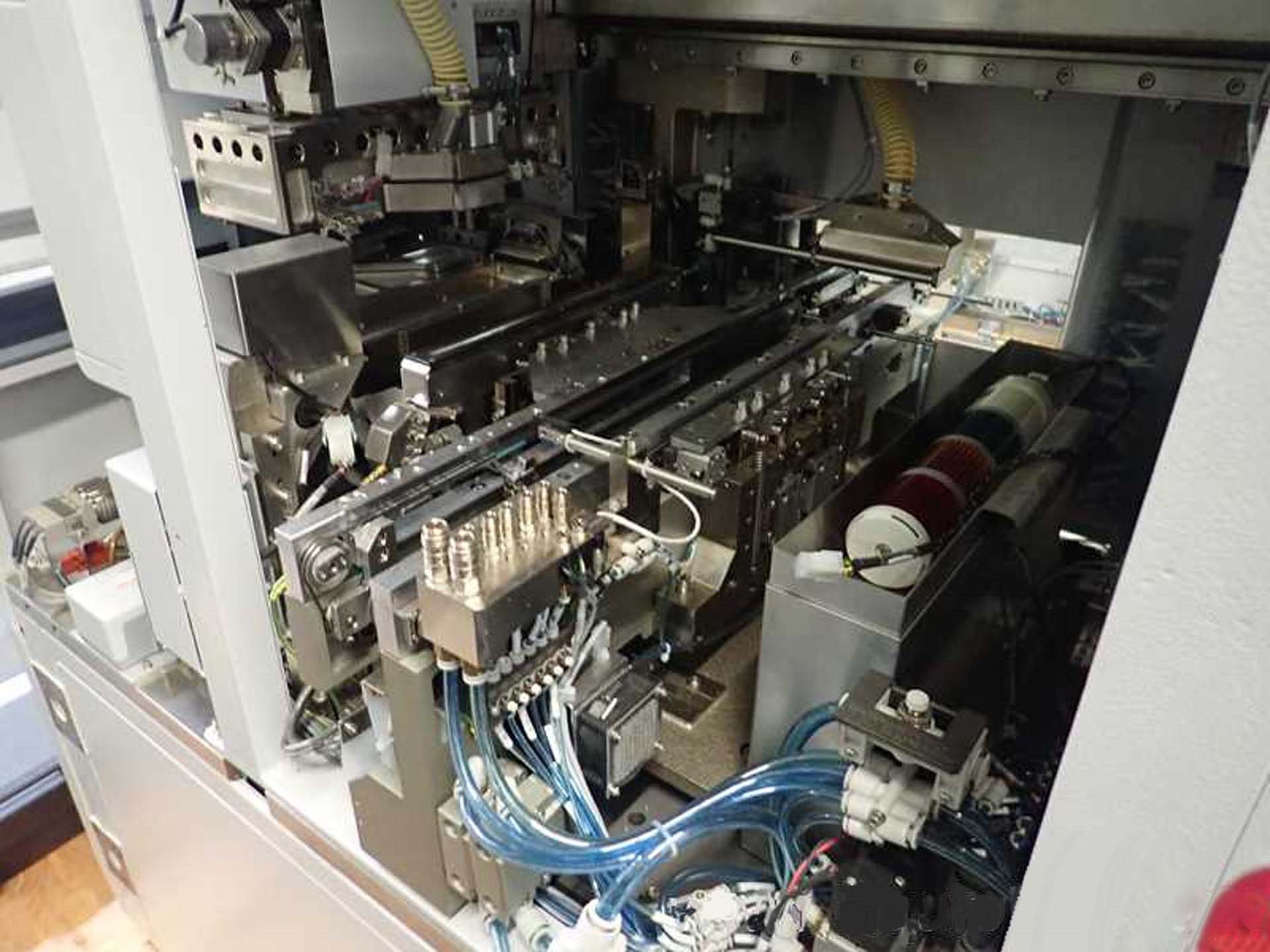

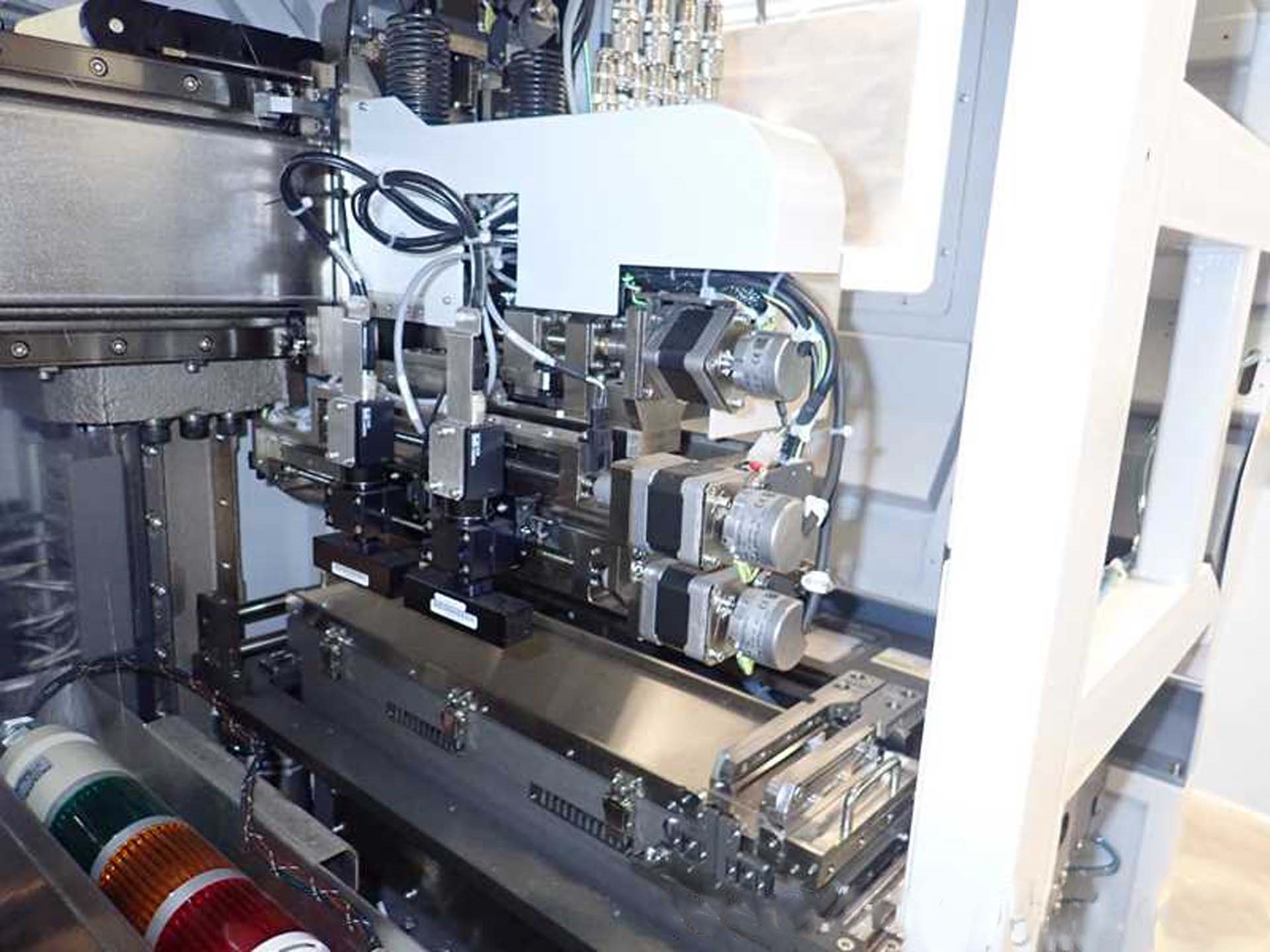

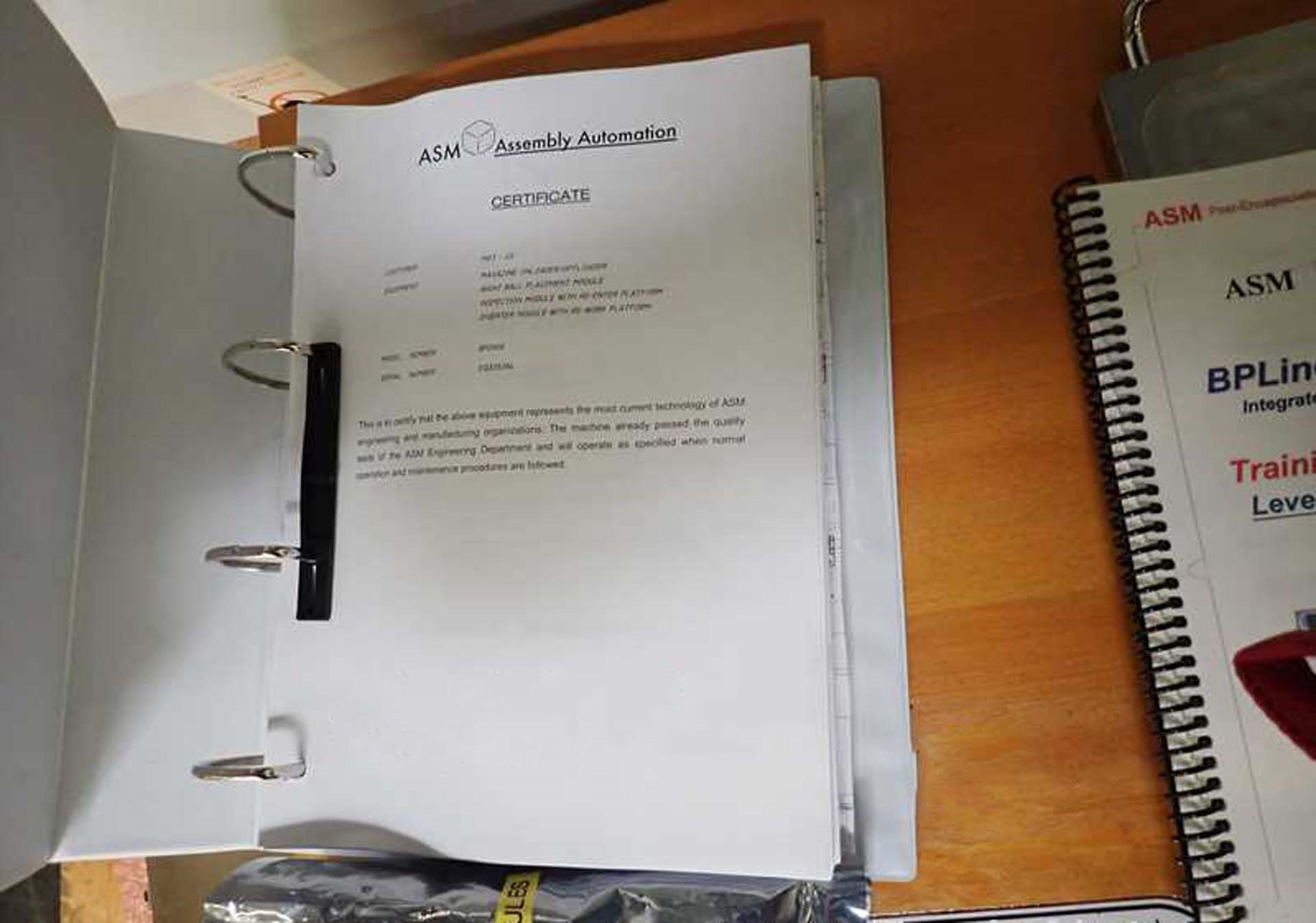

Ball placement system

Includes:

Slim KIC 2000

BP 2000 Set kit box

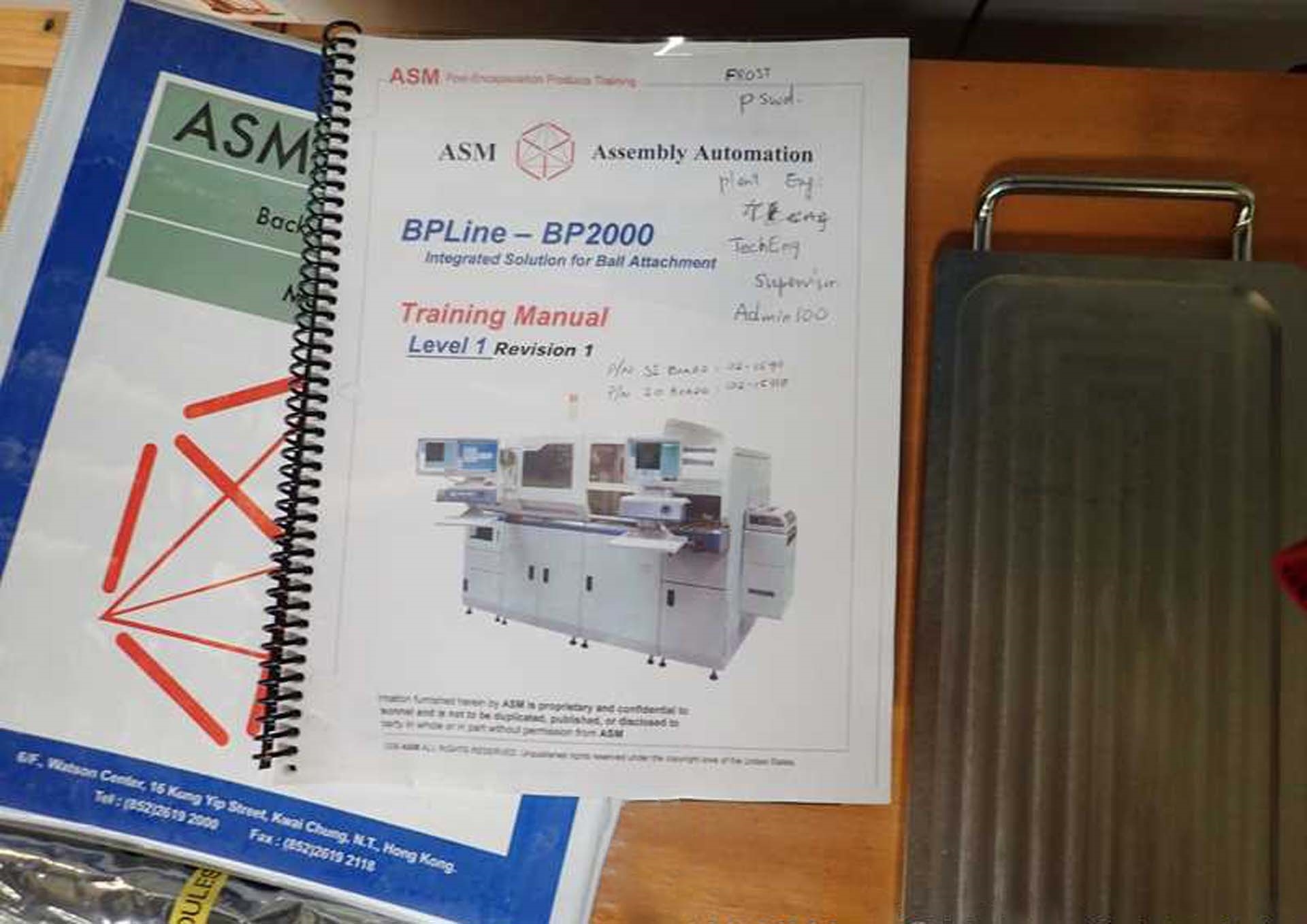

BP Line-BP 2000 Training manual level 1 Revision 1

2010 vintage.

ASM BP 2000 is an advanced pc board assembly and manufacturing equipment designed for high production environments. It utilizes an integrated 5-axis machine vision system and sophisticated software control unit to provide an automated and rapidly deployable solution for assembling pc boards. The machine can handle up to four pc boards simultaneously to achieve higher throughput and design flexibility, featuring automatic loading, alignment, routing, mounting and soldering capabilities. The tool features an innovative design that uses cameras to precisely locate the components prior to mounting and soldering. This imaging asset obtains complete information on the components to be assembled and identifies alignments. This feature enables fast and accurate assembly of pc boards, which is great for repetitive production processes. BP 2000 model consists of two parts - an Advanced Component Mounting Station (ACMS) and an Automated Soldering Station (ASS). Both of these work together to quickly and accurately perform pc board assembly. The ACMS is responsible for handling all the components and making sure they are in the correct position, and also includes a height detection equipment to produce more uniform solder joint quality. The ASS is tasked with precisely soldering components to the pc board, with advanced soldering techniques for high-precision applications such as the integration of micro-BGA's. In addition to assembly and manufacturing, ASM BP 2000 system features integrated quality assurance and process control systems. The unit comes with advanced camera vision capabilities to detect and reject misalignments and defects, and a complete database to track all data related to production. It features an integrated software interface to manage process parameters and adapt to different operations, enabling operators to adjust parameters to suit particular production requirements. Additionally, an onboard machine diagnostic tool to detect and diagnose potential causes of failure is also available. Thanks to the integrated camera vision tool and sophisticated software control asset, BP 2000 offers an automated and rapidly deployable solution for pc board assembly and manufacturing. This model ensures high throughput, precise alignment, and higher quality solder joints to maximize production efficiency and reduce costs.

There are no reviews yet