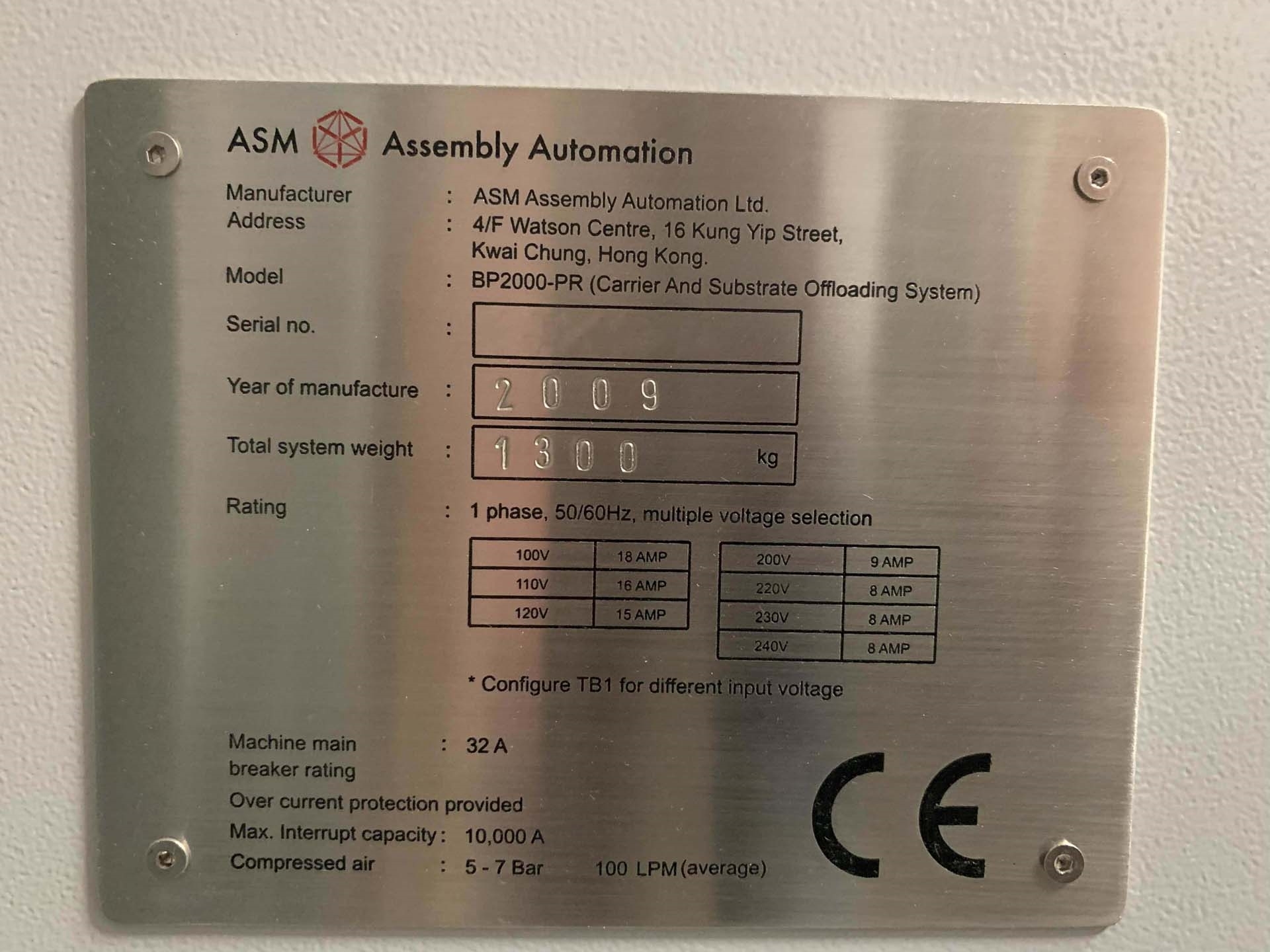

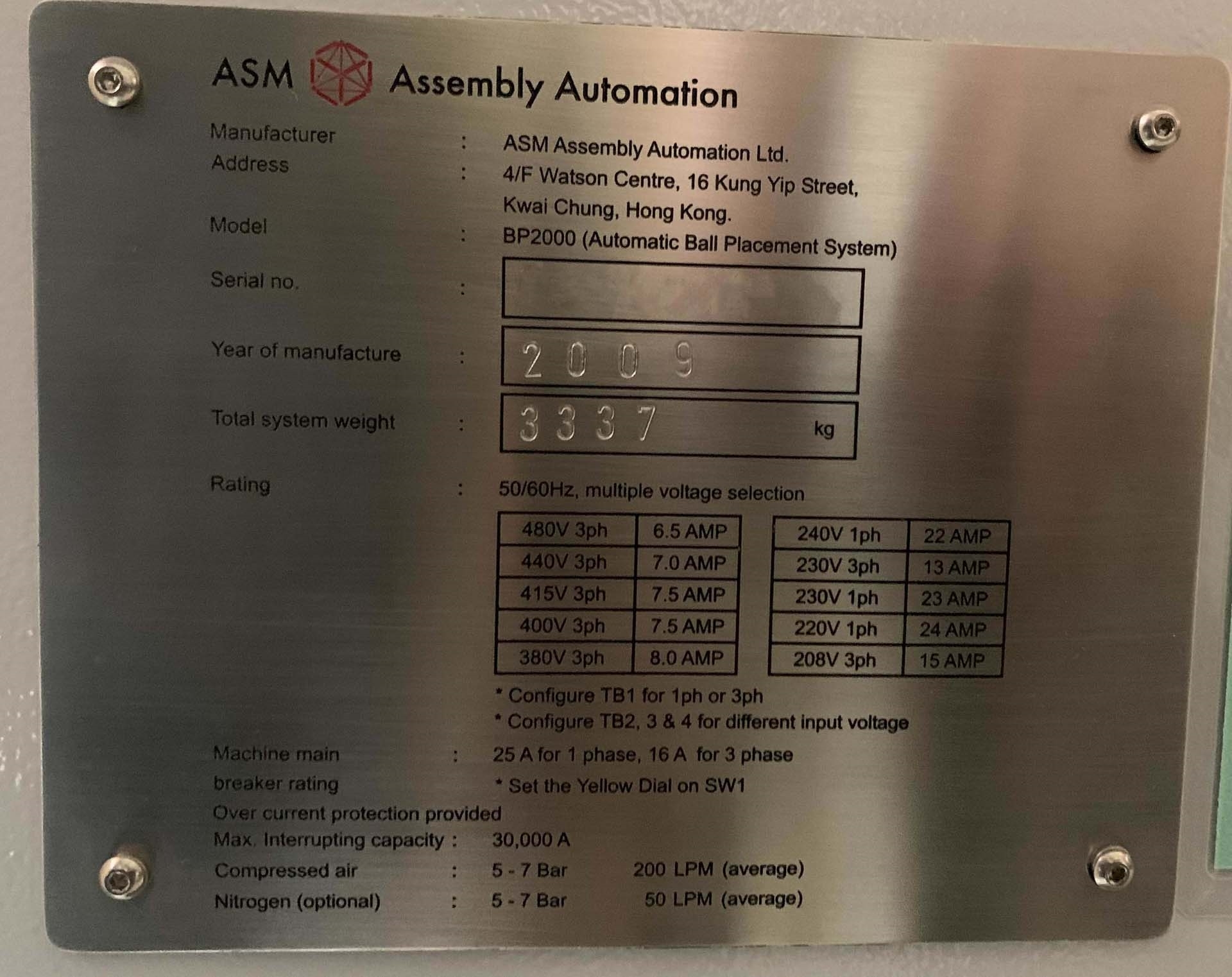

Used ASM BP 2000 #9249668 for sale

URL successfully copied!

Tap to zoom

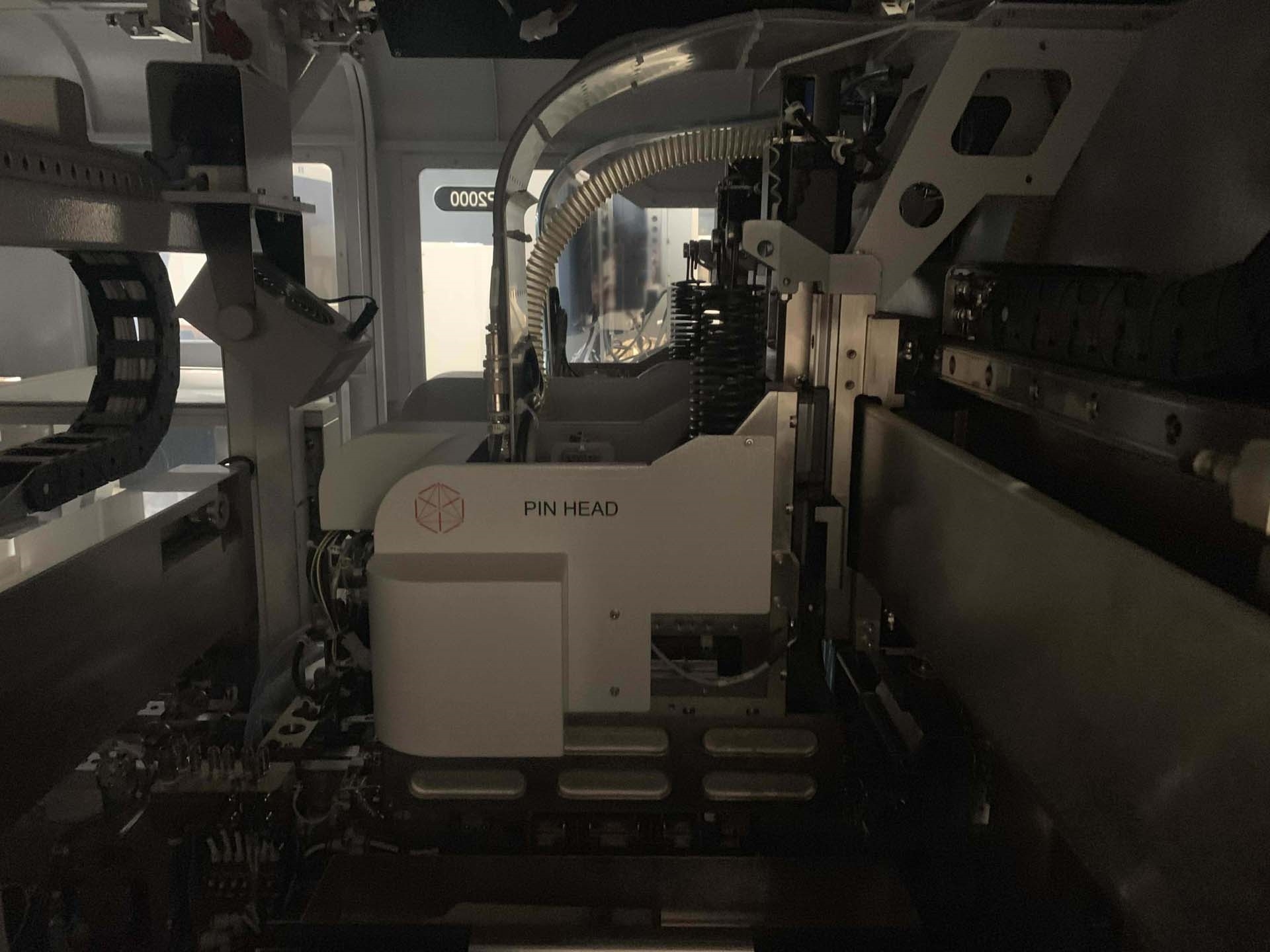

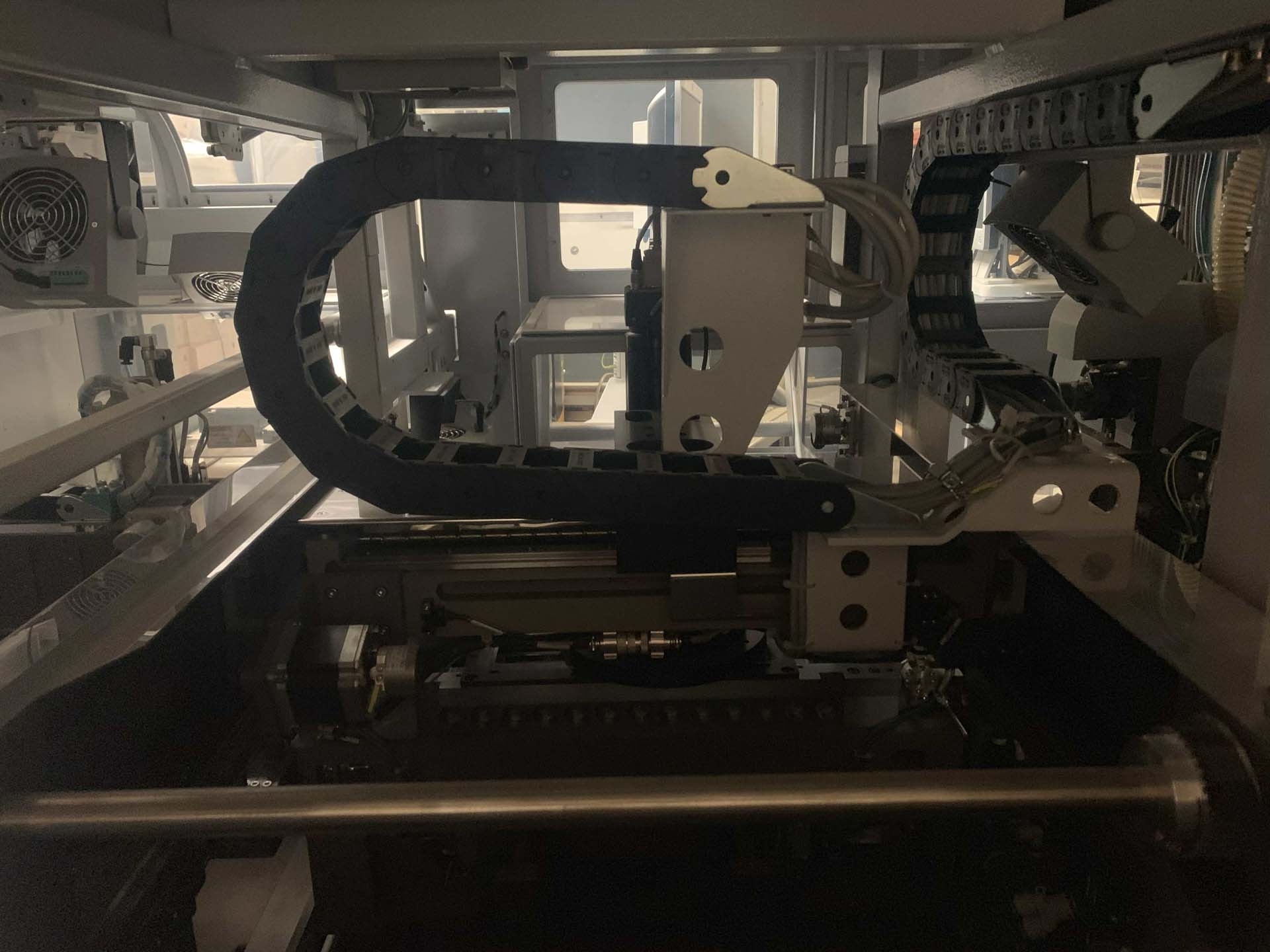

ASM BP 2000 is an automated equipment for pc board assembly and manufacturing. It consists of a complete assembly line with all the necessary machinery and equipment for assembling printed circuit boards (PCBs). The system is designed to provide high quality, efficient, and high precision for the assembly of PCBs. BP 2000 has several automated features such as the ability to assemble components with up to four layers of components stacked on top of each other. The unit also includes an integrated vision machine, measuring software, and interface modules. ASM BP 2000 utilizes robotic arms for rapid component placement onto the board. The robot arms are equipped with special grippers that can accurately place and manipulate components, ensuring precise alignment and positioning. It also has a built-in detection tool to detect and stop potential errors. The asset is capable of assembling up to 12,000 components per hour. BP 2000 model is also designed to be highly efficient. It has advanced programming capabilities which enable it to run an optimized cycle without any manual intervention. In addition, the equipment has the ability to quickly switch programs. As such, it can easily adjust to changing production needs. This allows for quick customization of the assembly process. The system also has several safety measures built in to ensure the safety of the operators. It has built-in safety doors and an emergency stop button to prevent any accidents from occurring. There is also the ability to run a comprehensive data-check which can detect any potential errors during the assembly process. ASM BP 2000 unit is also equipped with several data tracking and monitoring features. This allows the user to better control the assembly process and ensure high accuracy and reliability of the PCB assembly. The machine can track lead-time and performance data as well as provide statistical analysis. BP 2000 tool is also designed for use in a variety of environments. It is capable of operating in temperatures from -10°C to +55°C and humidity levels between 0 and 95%. This makes it suitable for a wide range of assembly applications. Overall, ASM BP 2000 is a highly efficient and reliable asset for automated PCB assembly and manufacturing. It is capable of producing high quality, accurate, and consistent results in a wide range of production environments. The advanced safety measures integrated into the model make it extremely safe and reliable for use.

There are no reviews yet