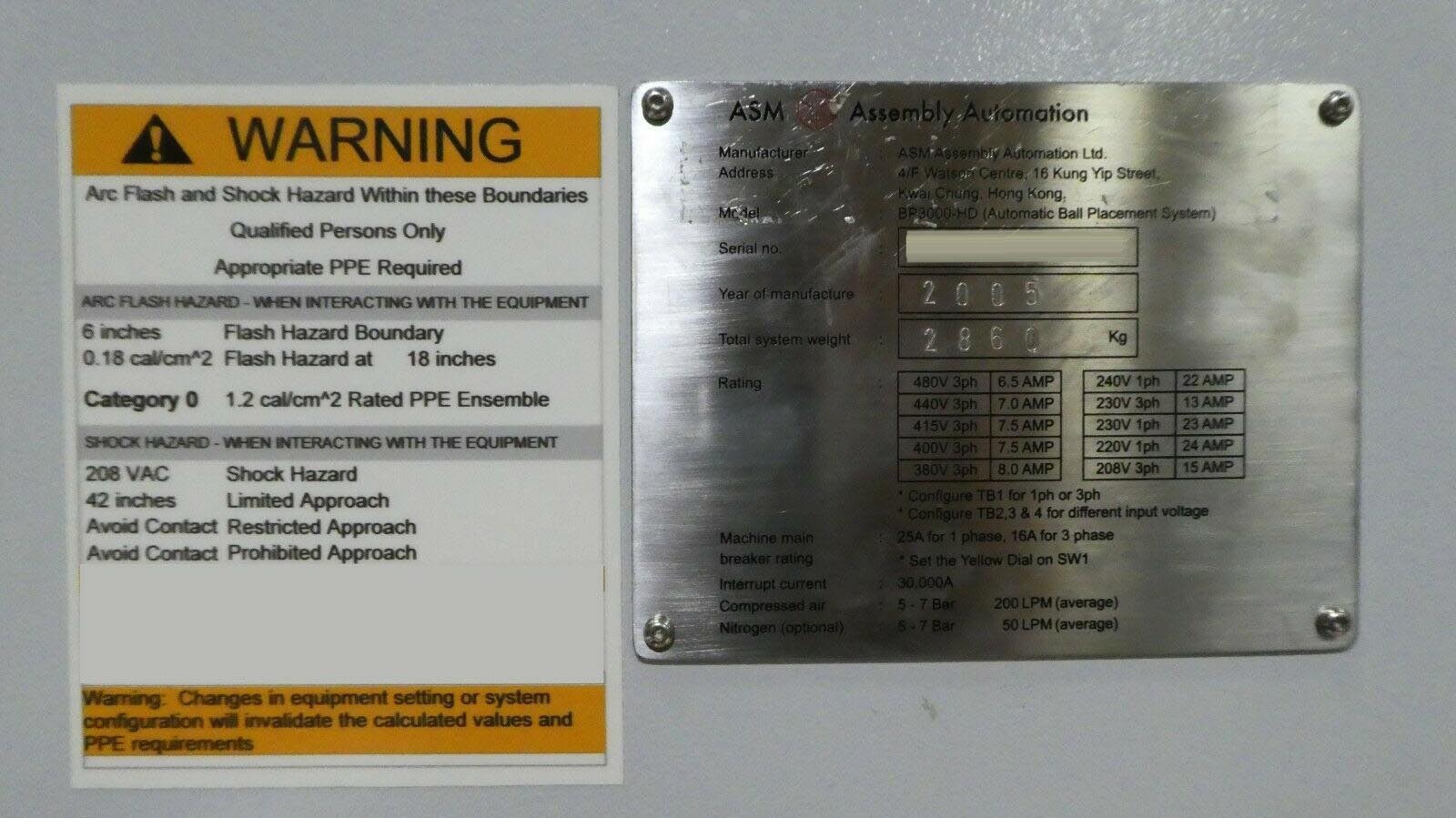

Used ASM BP 300 HD #9384047 for sale

URL successfully copied!

Tap to zoom

ID: 9384047

Vintage: 2005

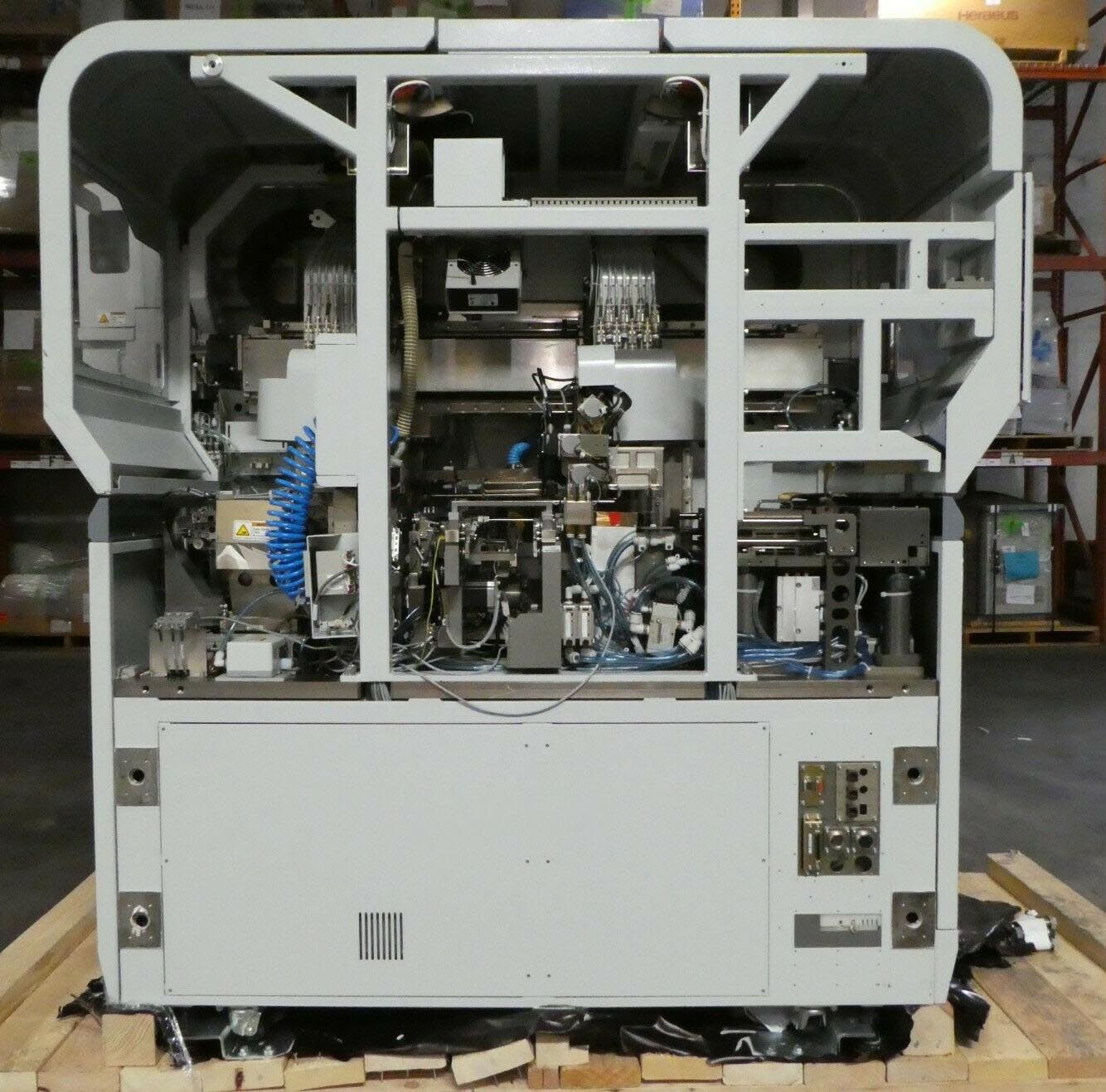

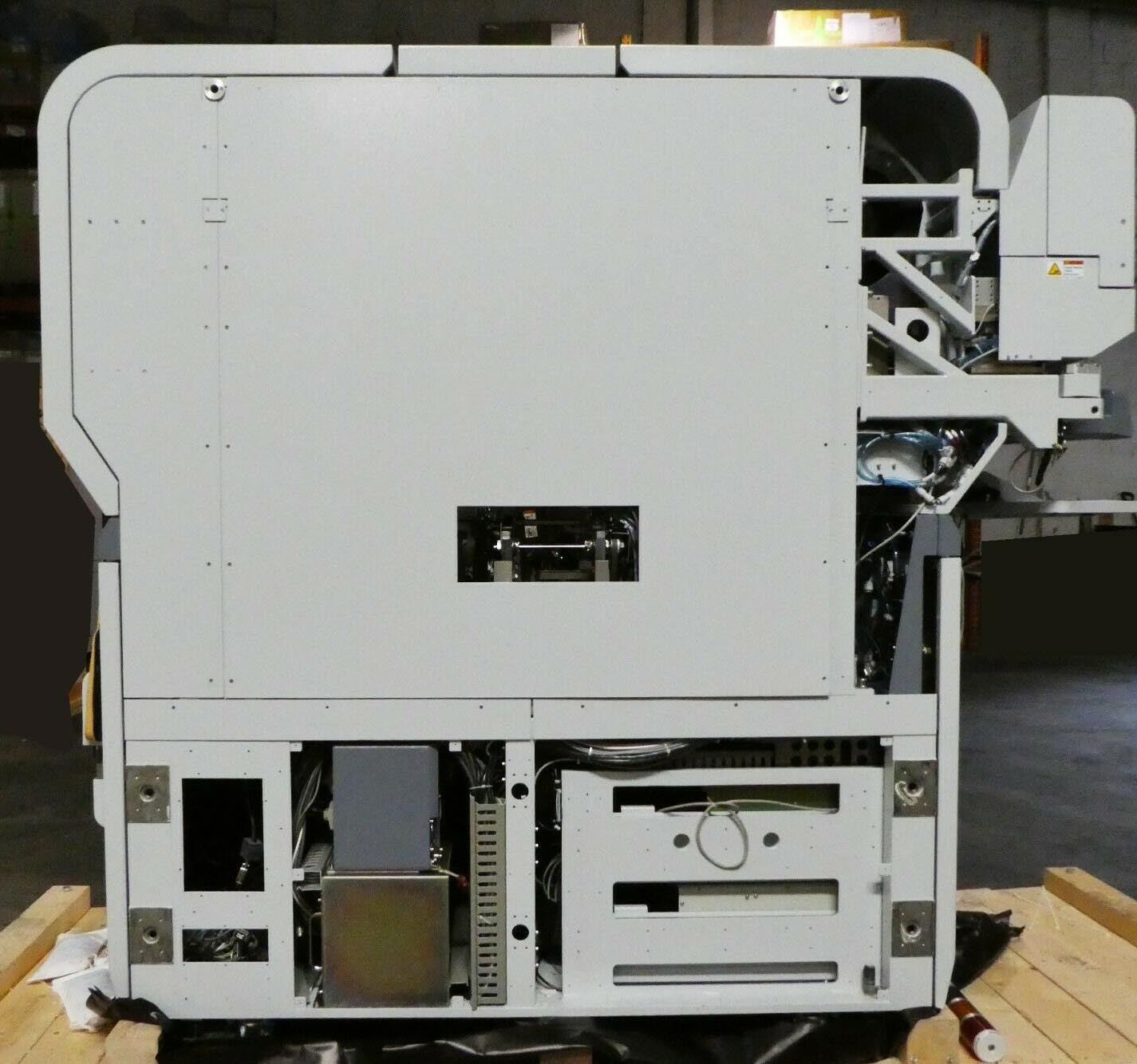

Automatic ball placement system

Inspection and diverter

Ball placer:

Left

Right

2005 vintage.

ASM BP 300 HD is a powerful pc board assembly and manufacturing equipment that provides an integrated solution for the complete assembly of printed circuit boards (PCB) quickly and accurately. This system provides flexible automation, high-volume production, and cost-effective material management for all types of product runs. BP 300 HD is designed to simplify the entire PCB assembly process, from receiving components to manufacturing the end product. The unit features a high-speed vision machine that can find and place components with an accuracy of up to 0.005". The intelligent storage tool can store up to 8,500 different components so that components are always available when needed. The asset's real-time monitoring allows users to track progress with production in real time, ensuring that the entire process runs smoothly and efficiently. The model is both expandable and networkable. It can be used to assemble single or multi-layer PCBs up to 35 square inches in size. In addition, the equipment allows users to make use of various programming languages to create custom solutions for specific production needs. ASM BP 300 HD is capable of supporting up to 8 soldering processes from a single machine. Overall, BP 300 HD is a powerful and efficient system for assembly and manufacturing of PCBs. It offers high-speed automated vision for accurate component placement, intelligent storage unit, real-time monitoring, and expandability. The network capability allows multiple machines to be connected together and used for a variety of production runs. Its flexibility and efficiency make it an attractive solution for PCB assembly and manufacturing.

There are no reviews yet