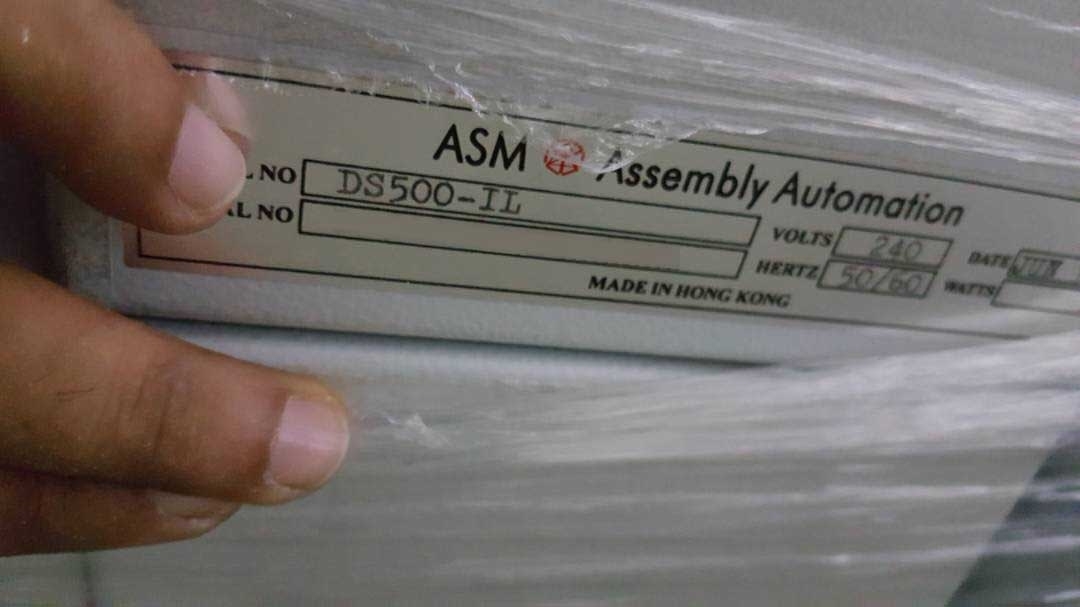

Used ASM DS-500IL #9102811 for sale

URL successfully copied!

Tap to zoom

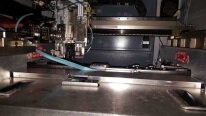

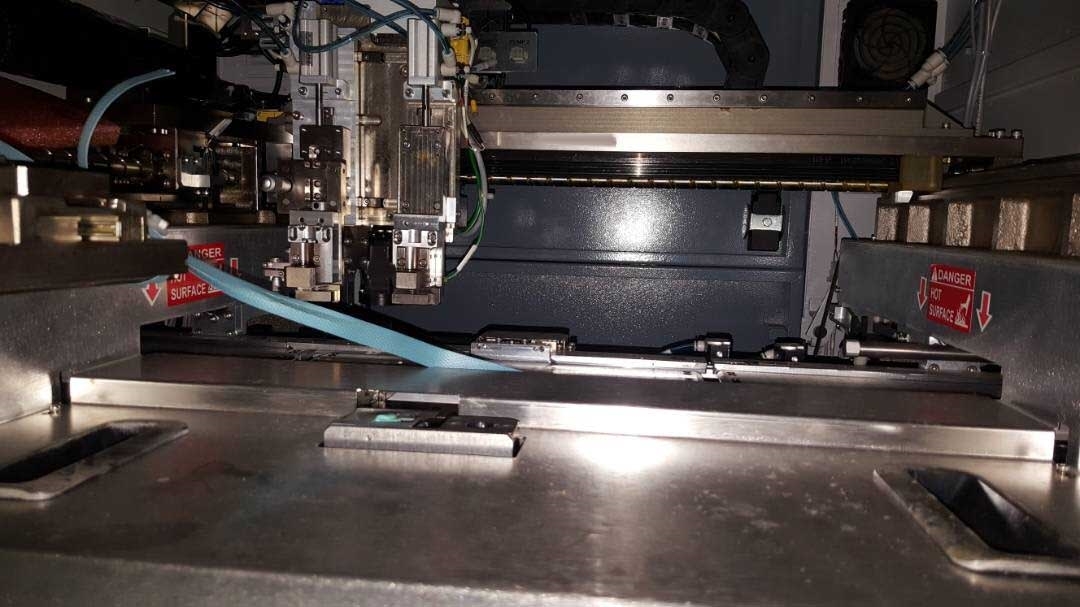

ASM DS-500IL is an advanced PC board assembly and manufacturing equipment designed to help businesses automate their production processes. The system integrates a number of components to ensure accuracy and precision in the production of PC boards. At the heart of the unit is a vision inspection machine, which examines the components on the board and evaluates the assembly accuracy. The inspection tool ensures that each and every component is correctly placed on the board. It also provides feedback which can be used to make adjustments quickly and easily. The assembly process is managed by a dedicated software application. This application is designed to provide a controlled environment, with well-defined rules for the placement of components and a traceability log which allows the user to trace which facility the board was manufactured in. Once the components have been placed, the asset uses a high-power laser to create the solder joints that will hold the components together. This ensures tight joints which will not fail under strain. In addition, the model can detect shorts, as well as any placement errors. The equipment also features an automated test system which can accurately test the quality of each PCB. This allows users to ensure that each board meets their desired specifications. The testing unit can also generate reports which can be used to make sure that production runs are consistently meeting their standards. Finally, the machine is equipped with an optimization module. This tool allows users to optimize their designs and ensure that they're efficient and cost-effective. Overall, DS-500IL asset is an invaluable tool that helps businesses with the production of high-quality PCBs. Its integrated components ensure accurate assembly and testing processes, and its optimization module helps optimize design and ensure cost efficiency.

There are no reviews yet