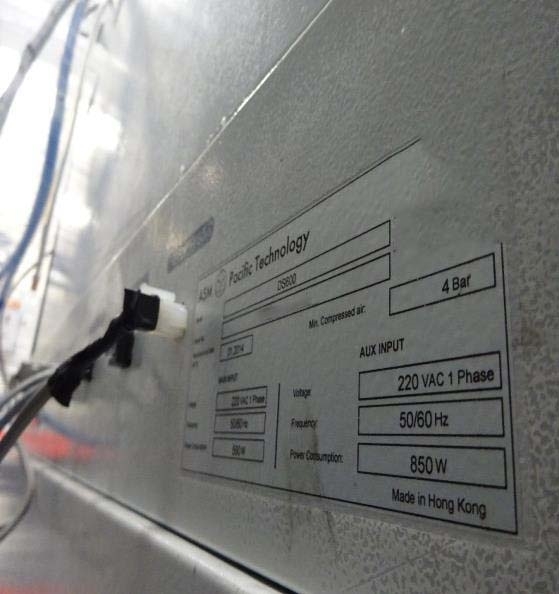

Used ASM DS600 #9280729 for sale

URL successfully copied!

Tap to zoom

ASM DS600 is a dynamic PC board assembly and manufacturing equipment for high-volume production. It uses modular, industrial automation technologies to provide a comprehensive, process-centric workcell solution. It is designed to increase efficiency, reduce lead times, and boost throughput for printed circuit board assembly and fabrication. DS600 is powered by a robust and flexible software control platform that simplifies setup, operation, and maintenance processes. This system comes with multiple placement and inspection technologies, including 3D and 2D optical defect inspection tools, vision-guided placement systems, and advanced machine vision. It also includes a selection of automation-ready feeders (SMT, axial, radial), a fully integrated handling unit, and simple assembly-area ergonomics. In terms of speed and accuracy, ASM DS600 is a top performer. Its high-precision vision machine can achieve extremely precise placement accuracy directly from the CAD data. This makes it ideal for processing even the most complex, mixed-component assemblies. Plus, its fast placement speed enables the board to move through the process quickly, reducing lead times. DS600 also offers a wide range of process monitoring and reporting tools. This includes real-time process data monitoring, traceability features, and data analytics. The tool is also designed to be flexible and easily integrated with a broad range of test and inspection systems. Finally, ASM DS600 comes with best-in-class service and support. It includes remote monitoring, free telephone-based technical assistance, tailored training programs, and access to dedicated field service technicians. There's also a comprehensive range of genuine spare parts and consumables. In conclusion, DS600 PC board assembly and manufacturing asset is a powerful and reliable platform for high-volume production. It offers fast, accurate placement, a variety of flexible automation technologies, extensive process monitoring and reporting capabilities, and top-notch service and support. All of this combines to make it the ideal choice for all your PCB assembly and fabrication needs.

There are no reviews yet