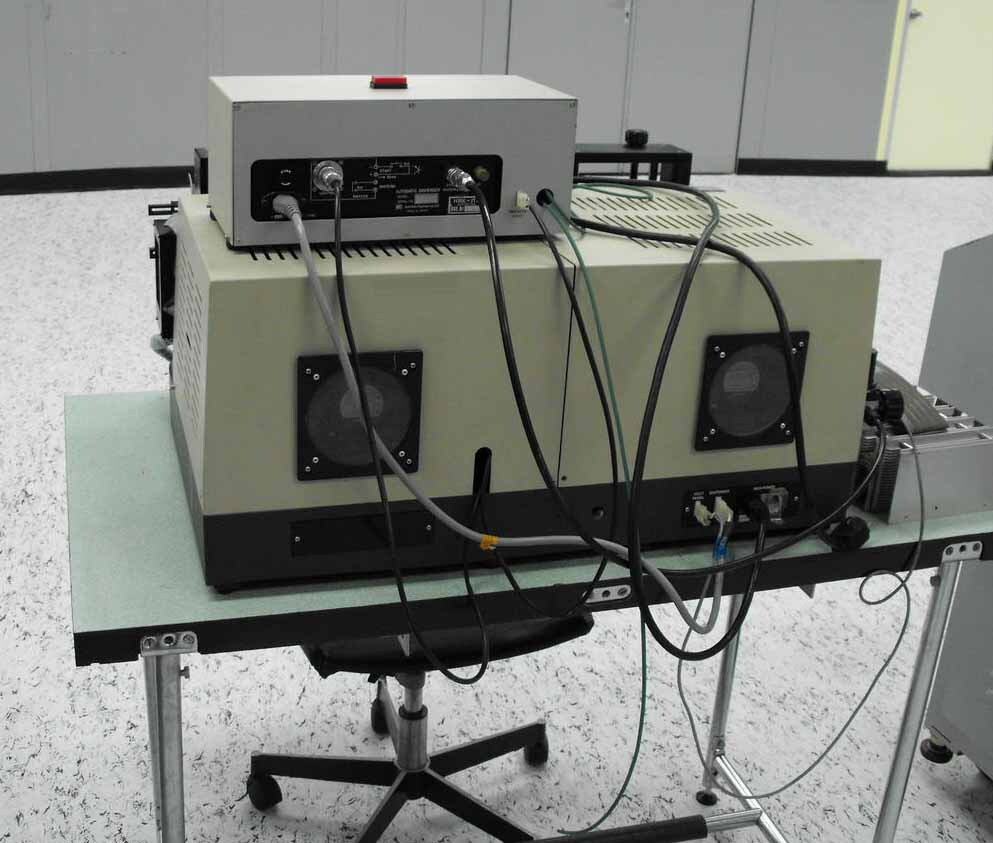

Used ASM PF-365-62 #9162233 for sale

URL successfully copied!

Tap to zoom

ID: 9162233

Vintage: 1997

Automatic leadframe liquid dispensing system

1997 vintage.

ASM PF-365-62 is an advanced, computerized pc board production and assembly equipment designed to produce high quality, highly efficient printed circuit boards (PCBs) quickly and reliably. It is an automated system that combines component placement and processing capabilities with the availability of advanced, cost-effective pc board design tools and visual technologies. The unit has the capacity to produce up to 500 boards per hour, allowing users to produce large numbers of boards in a single cycle. The machine offers advanced pc board design features including SmartDIRECT, which allows users to place components on the board in the optimal position for better electrical performance. The tool also features the FLEX engine, which provides users with the ability to test, recompile, and prototype boards without the need for dedicated circuitry. Additionally, the asset also features analytics functions and graphical analysis capabilities that allow users to understand and optimize design performance. The pc board assembly and production model also offers a wide range of resource-rich tools to optimize the production process. These features include automation solutions such as automated pick-and-place systems that are capable of quickly and accurately placing components onto the PC, as well as an array of software tools that enable users to quickly and easily program, debug, and control the equipment. The system features an intuitive and user-friendly interface, allowing users to easily access and control all the unit's functions. The machine also includes several safety features that ensure the safety and security of the production process. Other features include the ability to monitor production in real-time and to prevent errors and downtime using error-detecting and preventative actions. PF-365-62 is the ideal solution for those looking to efficiently produce pc boards quickly and reliably. The tool is reliable, efficient, and cost-effective, offering users advanced features, intuitive interfaces, and robust safety features. With the right resources and attitudes, users will be able to maximize the potential of the asset and use it to produce high-quality, cost-effective, and efficient circuit boards.

There are no reviews yet