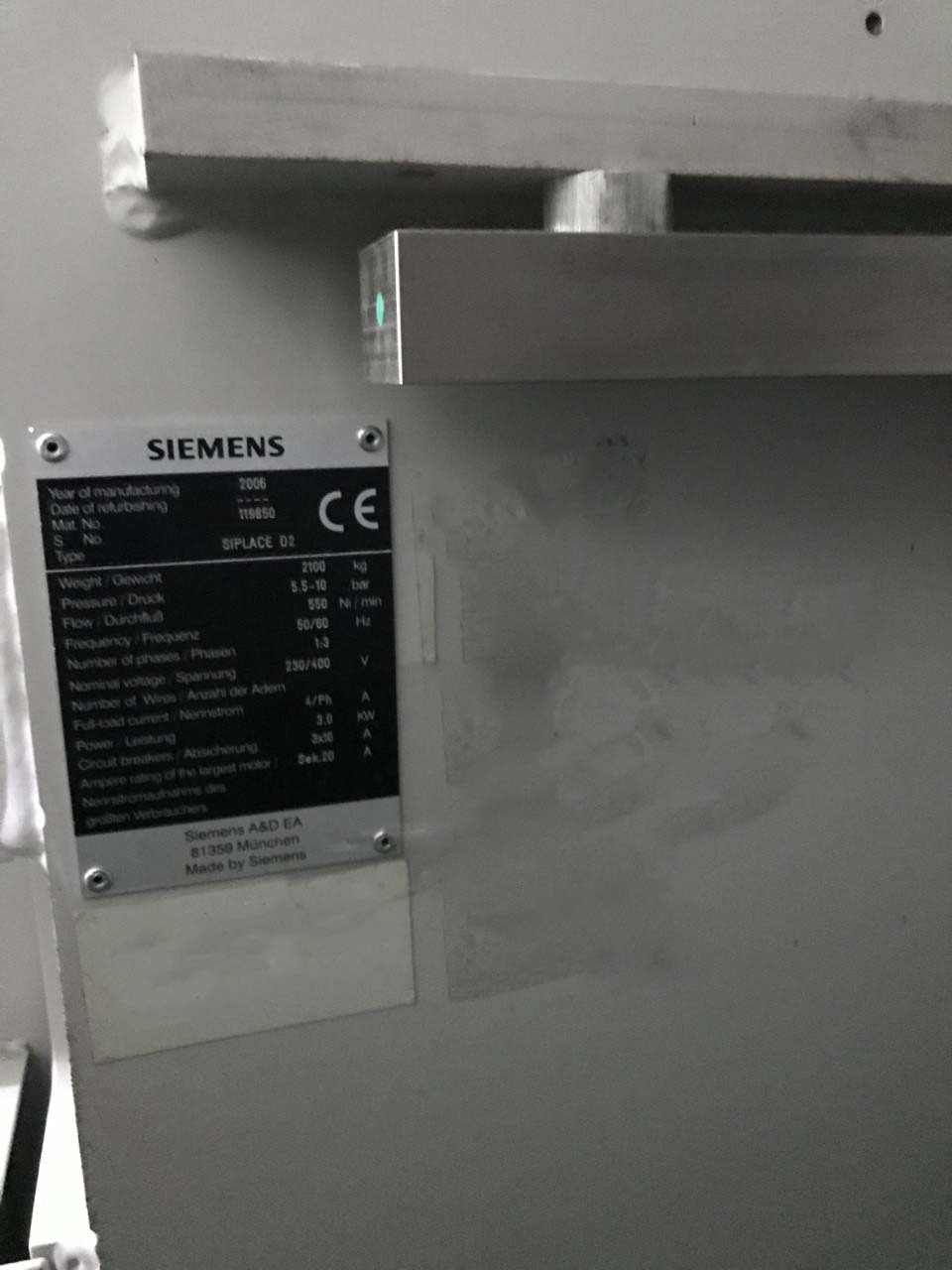

Used ASM / SIEMENS Siplace D2 #293636667 for sale

URL successfully copied!

Tap to zoom

ID: 293636667

Vintage: 2006

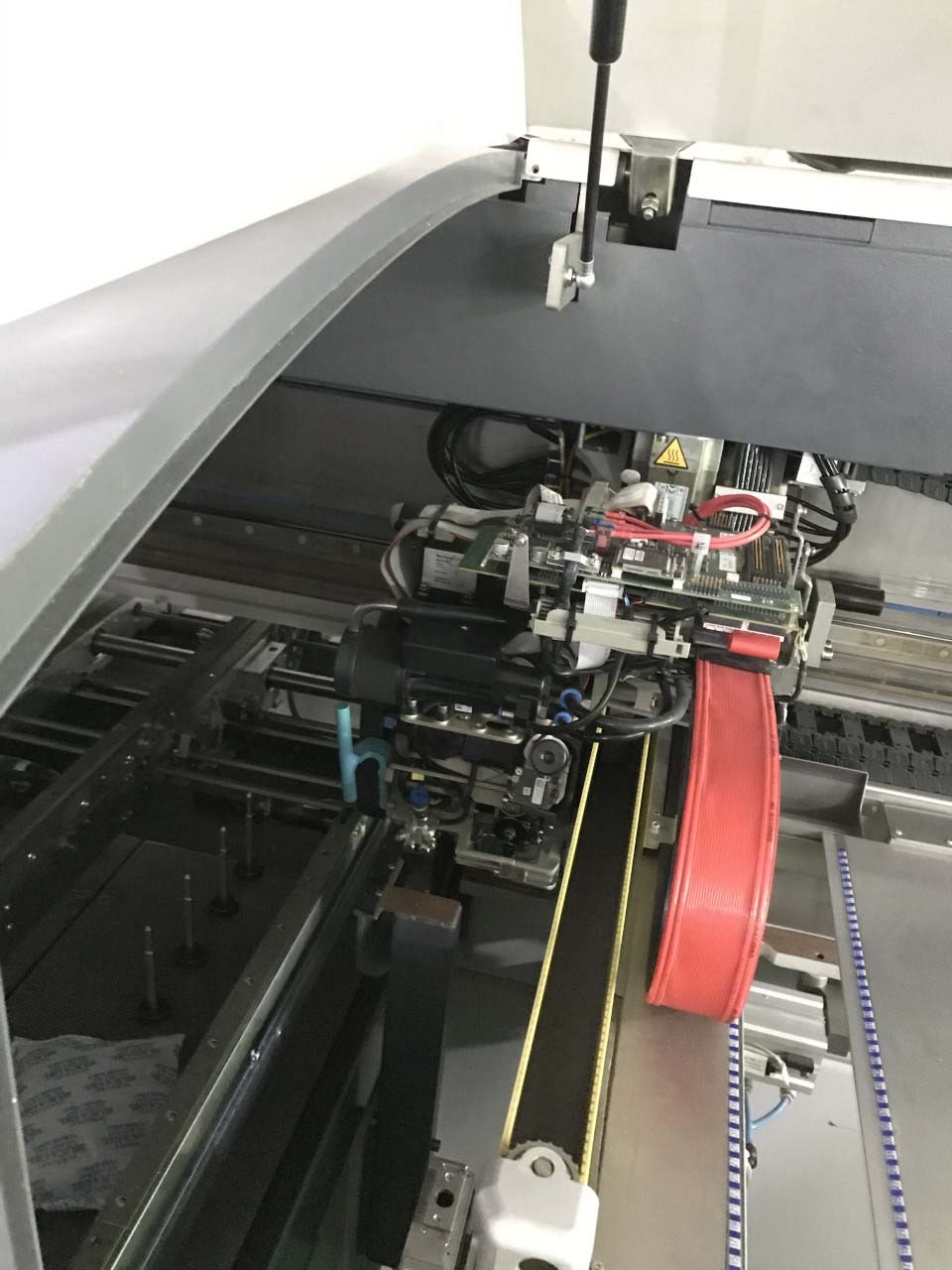

Pick and place machine

Double conveyor

Camera: Type #38

Feeders:

(10) 3 x 8

(5) 12 x 16

2006 vintage.

ASM / SIEMENS Siplace D2 is a PCB (printed circuit board) assembly and manufacturing equipment designed for high accuracy placement of components onto a PCB substrate. The system offers a full range of components from small surface-mount devices (SMD) to large heavy-duty components, and can support various board thicknesses, board sizes, and workpiece orientation. ASM Siplace D2 includes a high speed, precision placement head featuring automatic vision-based alignment and and a dual-lane feeder unit. These features provide high repeatability and accuracy, even with highly structured boards and mixed size components. The maximum speed of the placement head is 45,000 components per hour depending on product and application. The machine is also capable of self-calibration, ensuring consistent and reliable operation. SIEMENS Siplace D2 is equipped with a user-friendly operator control panel and a built-in graphic user-interface (GUI). This easy-to-use interface facilitates programming of applications and product data as well as monitor, control and manage production. The machine can be easily integrated into a manufacturing-area network and is capable of exchanging real-time production data with external databases and equipment. For efficient production the tool offers pick-and-place accuracy up to 0.1mm and prebond accuracy up to 0.04mm. A nozzle-cleaning asset is also included and helps to minimize the risk of contamination during production. Siplace D2 is also designed to reduce material consumption, with a balance of circuit board and component feeders, a fast PCB transfer model, and a chip tape feeder equipment. As a result, ASM / SIEMENS Siplace D2 offers a comprehensive production solution for the demanding requirements of modern electronic assemblies. The system is built for years of reliable operation, with a high-resolution color touch panel display and active safety systems to protect staff and components, resulting in a reliable, efficient, and safe manufacturing process.

There are no reviews yet