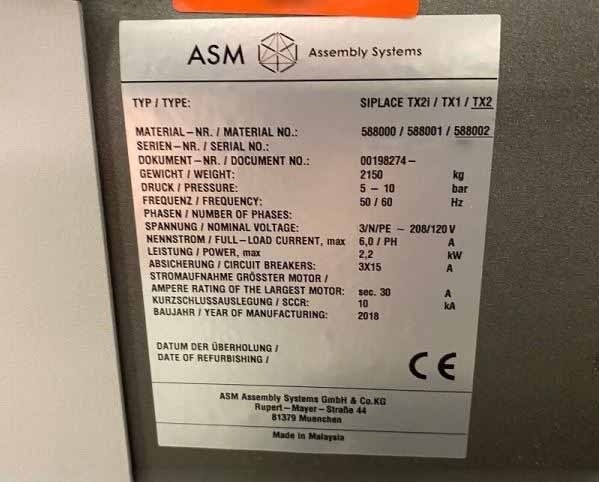

Used ASM Siplace TX2 #9293055 for sale

URL successfully copied!

Tap to zoom

ID: 9293055

Vintage: 2018

Pick and place machine

Head configuration:

CPP

Twin head

CPP:

CPP Mounted

CPP Camera: Type 30

Component range CPP with T30 camera: 01005 to 27 x 27 mm

Twin head:

Component range TH: 1.0 mm to .5 mm up to 200 x 125 mm, 25 mm tall

Twin head stage mounted (upward looking): Type 33

CPH: 28,500

2018 vintage.

ASM Siplace TX2 is a Complete PC Board Assembly and Manufacturing equipment which enables users to have complete process control via the Automatic Process Optimisation (APO) plus Dual Lane Technology. It is suitable for manual and automated assembly lines and provides a user-friendly solution for efficient manufacturing of complex PC boards. The system is also compatible with SME/EMC Standards. The TX2smt features a dual soldering unit which enables both traditional and surface mount technology (SMT) processes. It facilitates simultaneous soldering of two side of the board which reduces working time and cost. The Advanced Contact Pressure Machine (ACPS) ensures contact reliability between the components and the substrate. This improves accuracy and increases process reliability on critical components. Furthermore, the tool uses a series of sensors to monitor contact pressure in order to prevent a short-circuit on the board in case of incorrect loading. Siplace TX2 also provides precise imaging of soldering and assembly operations with a 3D X-ray Inspection (3DXI) which identifies incorrect component insertion and provides a visual verification. This is further supplemented by Optical Inspection (OI) asset which ensures accuracy in micro-assembly of components. Finally, the model also utilizes a 3D Soldering Control technology which ensures the soldered components meet all the required specifications. ASM Siplace TX2 supports both pallet and in-line systems, maximizing flexibility in meeting customer requirements. It also offers simultaneous soldering and component placement on dual lanes and is capable of soldering boards up to 500mm x 400mm in size. The user-friendly software reduces programming time and helps improve process reliability at high efficiency. Moreover, the equipment also carries out automatic nozzle cleaning and No-Operation (NOP) detection for maximum performance optimization. In conclusion, Siplace TX2 is a user-friendly system perfectly tailored for efficient and accurate PC board assembly and manufacturing. It is a complete solution with automatic process optimization, dual lane technology, 3D X-ray Inspection, Optical Inspection and 3D Soldering Control technology, and also offers flexibility to meet customer requirements. With its user-friendly software and robust features, this unit is an ideal choice for customers looking for efficient production of complex PC boards.

There are no reviews yet