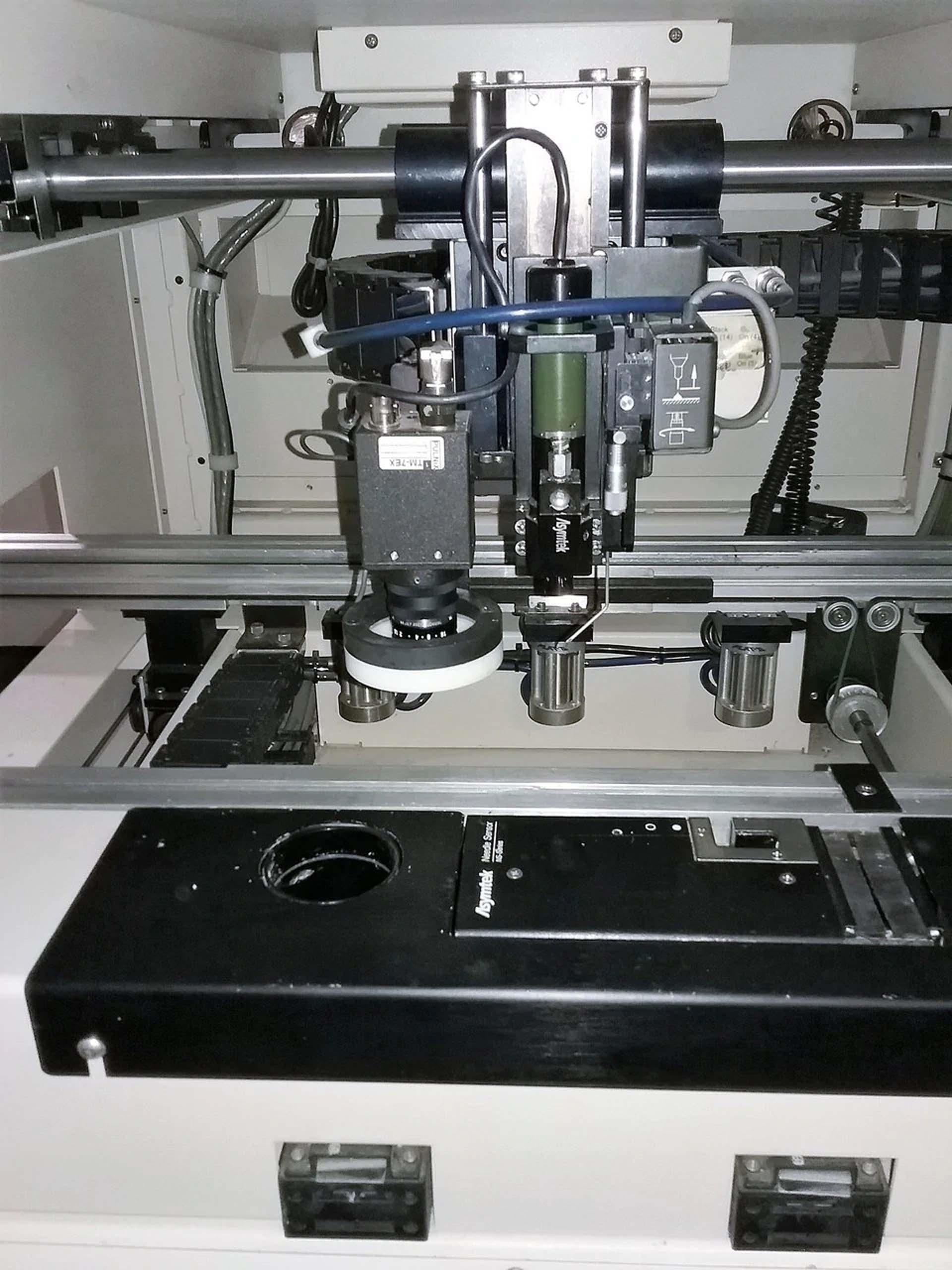

Used ASYMTEK A-612C #9285620 for sale

URL successfully copied!

Tap to zoom

ID: 9285620

Dispensing system

Board flow direction: Left to right

Belt track length: 39.5

SMEMA

80 PSI

Conveyor Sections

Length, 39.5"

Minimum width, 3"

Maximum width, 11"

Power supply: 120 V, 50/60 Hz, Single Phase.

ASYMTEK A-612C is an automated pick-and-place and soldering machine designed for printed circuit board (PCB) assembly and manufacturing. The equipment features a high-precision CNC gantry, a vision system for accurate component recognition, and a closed-loop motion profiler for controlling coordinates and speeds. It also includes an anti-static dust- suppression unit and a space-saving ultra-large multi-function platform. A-612C is capable of processing a range of component sizes from 0201 to 12mm, up to 1.7 million components per hour. ASYMTEK A-612C includes a moveable headsight conveyor, enabling it to place components at different angles for improved accuracy and repeatability. The adjustable position and speed of the conveyor accommodate a wide variety of board sizes, shapes, and components. The machine also features a multi-zone IR Senso-Rite reflow oven, allowing for different temperatures to be set in each area of the reflow chamber. This ensures uniform temperature throughout the coating process, which is essential for consistent and reliable soldering. A-612C also features an advanced software environment, which provides the user with easy programming and control. It can easily be customized to meet specific production and manufacturing needs, and provides users with the flexibility to create various recipes for a variety of processes. Furthermore, the tool has a data logging feature for recording inspection results monitored during placement, reflow, and soldering operations. ASYMTEK A-612C is designed to maximize manufacturing efficiency and throughput, and is ideal for assembling high density and mixed- technology complex PCBs. The asset's intuitive software and high-speed, precision placement make it capable of consistently delivering reliable and accurate component placement and soldering results. An integrated dust-suppression model makes sure your clean room remains clean and uncontaminated. With its reliable and robust design, A-612C is an ideal choice for high-end PCB assembly and manufacturing.

There are no reviews yet