Used ASYMTEK M-2000 #9267593 for sale

URL successfully copied!

Tap to zoom

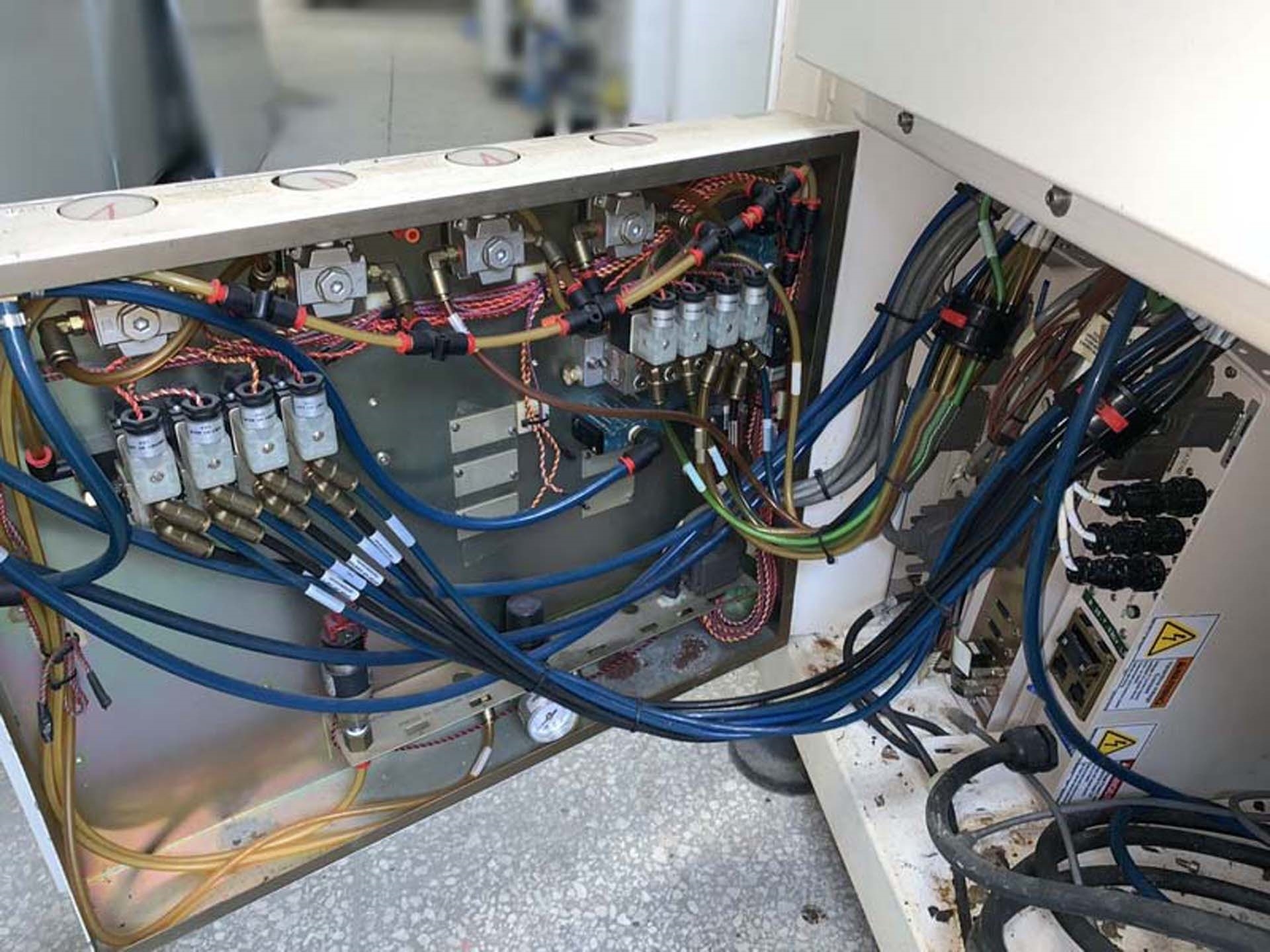

ASYMTEK M-2000 is a high performance pick-and-place and assembly equipment designed for the modern electronic manufacturing industry - from printed circuit board assembly through to full device assembly. The system provides an integrated solution for efficient production processes with a variety of components, including surface mount devices (SMD) and through-hole components. M-2000 consists of a pick-and-place head, conveyor unit, computer-controlled indexing table and inspection tracks. The pick-and-place head is equipped with vacuum, mechanical force and camera vision capabilities. Its innovative vision machine provides precise placement of components on printed circuit boards (PCB), eliminating time-consuming manual processes. The conveyor tool transports the PCBs through the placement and assembly processes, while the indexing table orients and indexes the PCBs to facilitate efficient production. The satisfaction of even the most demanding applications is also ensured through ASYMTEK M-2000's modular construction, allowing users to customize the asset to their individual needs. All modules, including feeders and software, can be upgraded to adapt to changing production demands. Furthermore, M-2000's fast and precise placement and inspection capabilities reduce processing time and required resources, driving down production costs. The model offers added convenience in the form of an integrated 4-camera equipment for tracking components, enabling greater accuracy and flexibility in addressable components. Also, to ensure the accuracy and consistency of production, ASYMTEK M-2000 is equipped with an automated error control system, providing real-time alerts for misallocated components. In conclusion, M-2000 is the ideal solution for efficient pc board assembly and manufacturing, allowing organizations to shorten time-to-market while reducing cost and ensuring high throughput throughout all stages of production.

There are no reviews yet