Used ASYMTEK M-2000 #9267598 for sale

URL successfully copied!

Tap to zoom

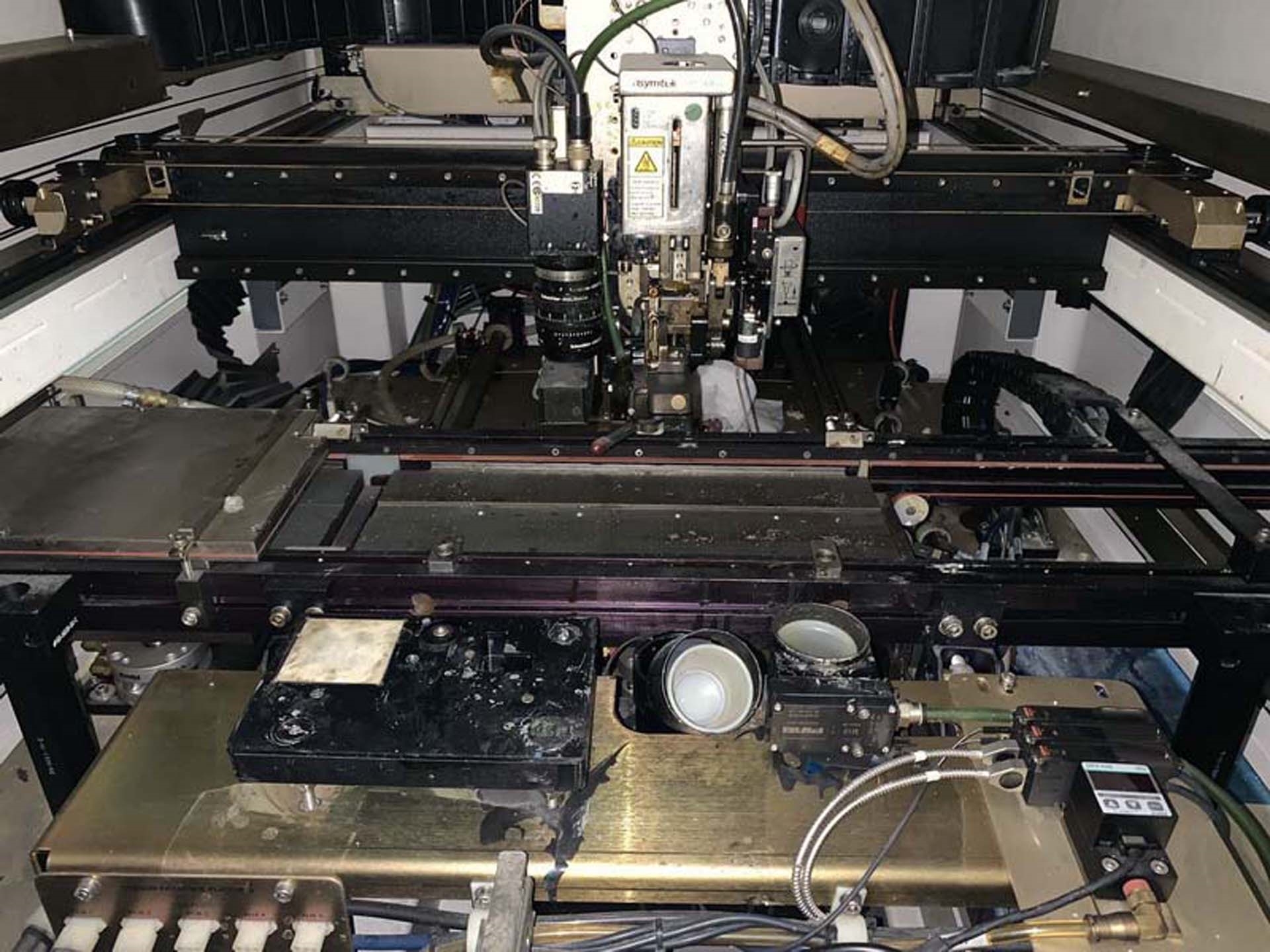

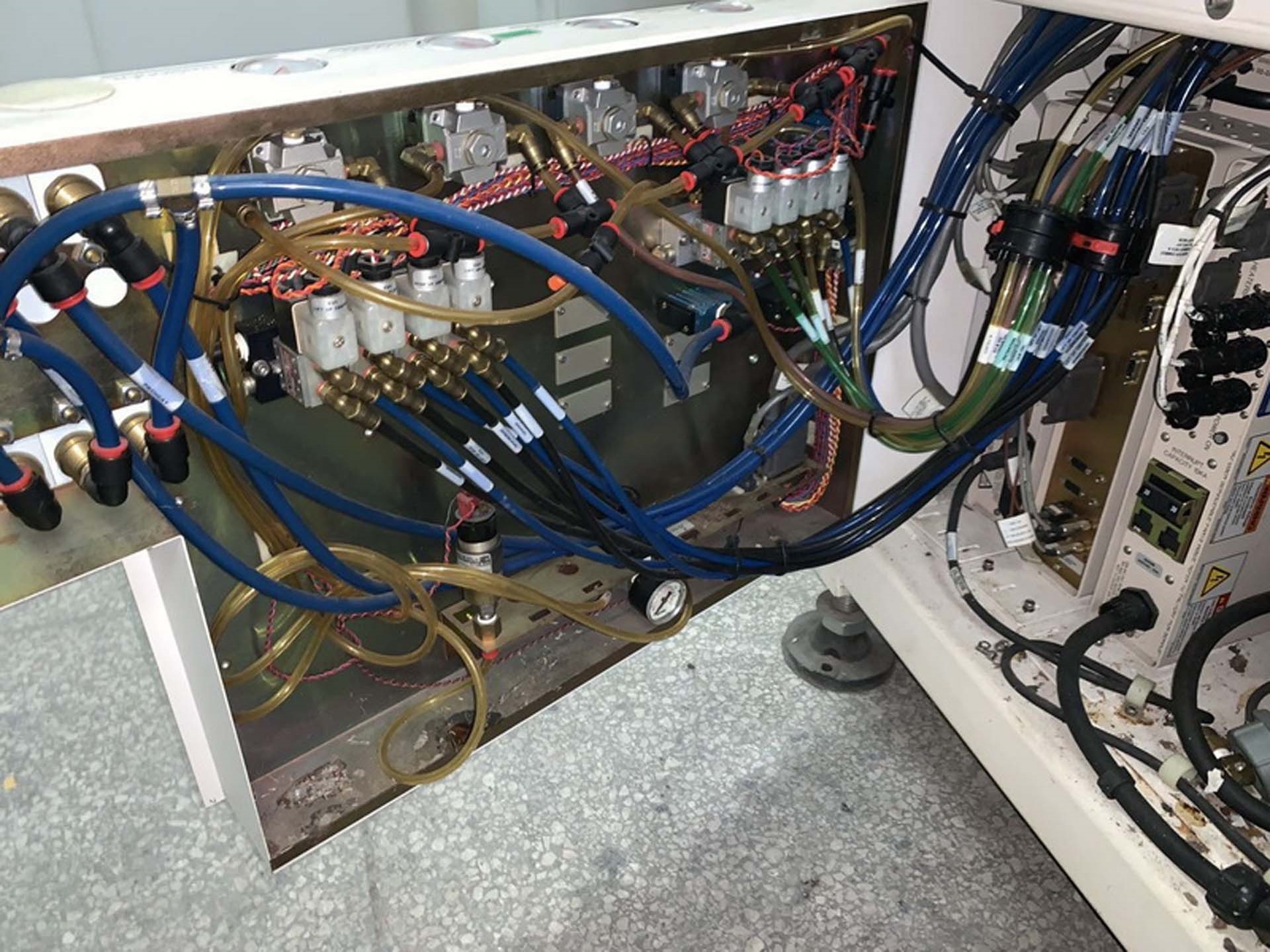

ASYMTEK M-2000 is a computer-controlled manufacturing equipment for PC board assembly and manufacturing. The system includes a workstation and an integrated conveyor unit for manufacturing processes. M-2000 is designed to provide highly accurate and precise assembly and manufacturing of a variety of PCBs in a cost-effective and efficient manner. ASYMTEK M-2000 machine includes an automated training station for learning new processes, which guides operators through the process and tracks progress. The tool also offers multilayer, high-speed optical inspection for instantaneous identification of defects. This is done with advanced camera technology combined with image-processing algorithms. The machine itself is a robot-like asset that is constantly in motion. The machine is designed to move parts, process components, and install and review PCBs with accuracy and speed without human intervention. It has three axes of movement supported by both mechanical and electronic components. The Intelligent Feedback Control (IFC) model on M-2000 ensures high throughput and accuracy. IFC helps to maintain stability and optimal performance by monitoring the equipment's movements in real-time. ASYMTEK M-2000 system also has an Auto-Programming Unit (APS). This large-scale programming machine assists in the development of processes to be followed by M-2000 robot. It can be used to create detailed applications for assembly and manufacturing. In addition, ASYMTEK M-2000 offers a flexible vision tool with interchangeable lenses. This allows users to select the most suitable lens for the task. The asset also has a high-resolution monitor for better visualization and control of the vision model. Finally, M-2000 provides automated traceability for all manufactured goods. This includes real-time data logging and tag printing of all components that pass through the equipment. This enables users to confirm the quality of their products. Overall, ASYMTEK M-2000 is a highly efficient and accurate system for PC board assembly and manufacturing. It has a number of features including automated training, high-speed optical inspection, an Intelligent Feedback Control Unit, an Auto-Programming Machine, a flexible vision tool, and a traceability asset. All of these features combine to provide a highly cost-effective and accurate solution for assembling and manufacturing PC boards.

There are no reviews yet