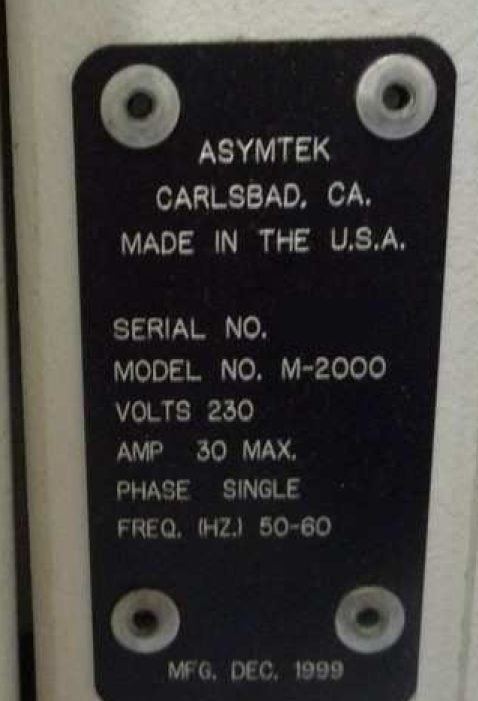

Used ASYMTEK M-2000 #99191 for sale

URL successfully copied!

Tap to zoom

ID: 99191

Vintage: 1999

Glue Dispensing Machine

Available spares:

Qty Part No. Description

7 193840 swab, rnd/rnd tip, 10/pkg

2 392141 assy, needle heater

1 7200581 seal,peek, 313x125

2 SA-603 assy, syringe

2 SA-606 assy, syringe

3 SA-606C assy, syringe

2 SA-610 assy, syringe

3 SA-635-C assy, syringe

3 SA-610-C assy, syringe

50 42-0225 luer adaptor,male-fem,plastic

1 7205830 assy, ht sensor, removeable probe

1 193029 assy, motor, enc, dp-3000

1 48-8105 tool,seal removal,plastic

1 381985 heater block assy, luerlock

1 62-0651-00 assy,mlfs,long cable

10 200487 spring,.25id,3l

2 KS-01 set, syringe

43 210765 assy,feed tube

50 42-0028 female luer lug style with 1/4 hex to 10-32

6 BRU-07-01 tube brush

2 03-0688-00 bearing, lower screw

1 SK-7001 kit,seal,dv-7000

1 210720 assy, thermal control

3 03-1118-00C clip 2,5/60z

4 03-1134-00B clip0,3occ

1 41-0112 1/4 x 5/16 open end

1 7209665 sleeve, hs probe, replaceable

1 196629 tool,insert,seal,dv7000

1 210753-8 nozzle,low vol-dt9000

1 210753-16 nozzle, low vol, 0,400, dj-9000

1 210753-6 nozzle,low vol-dt9000

3 42-1425 needle,25 ga 12pcs-pack

4 42-1420 needle,20 ga 12pcs-pack

4 42-1421 needle,21 ga 12pcs-pack

2 20810 machine connector

2 dispensing component kit 5100

1 42-0530 valve, dv-05a

3 42-0386 flatwall piston 20 pc

2 DJ-9000 dispense jet, 9000

2 315668 safety valve 60 bar mx pneu

2 58-0030 cup,dixie 200/pkg

75 62-0596-00 assy, sensor,mag,fluid,2.5/60z

5 40-1960 cartridge, 60z

1 06-4501-00 pwr, cable, eur

1 06-2142-22 upstream machine cable

1 64-1702-00 assy,precision regulator

1999 vintage.

ASYMTEK M-2000 is a PC board assembly and manufacturing equipment using automated vision-guided technology. It has been designed to provide high performance, flexibility and process precision while ensuring low cost of ownership over the lifetime of the system. The unit uses an integrated component inspection machine and component feeders to detect component misalignments, component polarity and component type. This allows for verification of component placement accuracy and component type during component placement. It also has an integrated vision tool for automated optical inspection of component placement. This inspection asset checks for component presence, component polarity, component placement accuracy, solder joint inspection and component type verification. It can be used for both lead-free and leaded assembly operations. The component placement model included on M-2000 uses a XYZ capability to place components accurately onto the PC board. It has high speed autotuning software to quickly calibrate the machine to the board. It also has a wide range of pick-up heads and component types that can be used to assemble various sizes of components. It has an automatic nozzle cleaning feature to ensure that the placement accuracy is maintained. In the equipment, dual conveyor feeders handle single sided or double sided boards. It can also handle mixed technology board manufacturing. The board handling system organizes boards onto different conveyors allowing for parallel processing operations. The unit can be integrated with resource management systems for optimal board handling. ASYMTEK M-2000 has multiple machine configurations to meet different production requirements. It also provides cost efficient engineering solutions that are easy to install and maintain. It is compatible with multiple software packages, including support for different IT infrastructure protocols. It has a touchscreen operator interface for enhanced user experience. M-2000 is a highly reliable automated tool that allows for repeatable manufacturing with lower chance of errors. It is flexible, easy to program and cost effective, making it ideal for customers looking to automate their PC board assembly and manufacturing processes.

There are no reviews yet