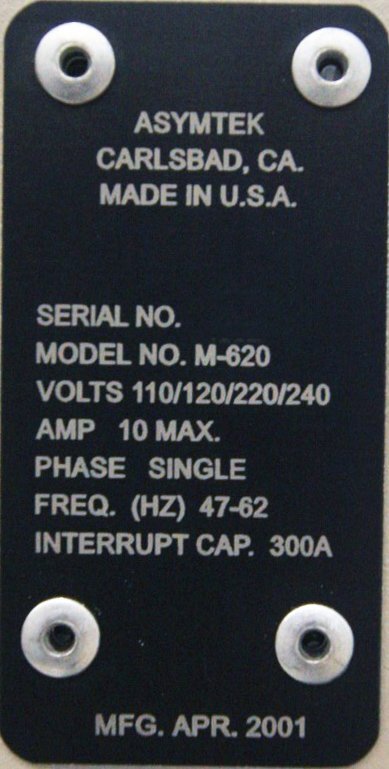

Used ASYMTEK Millennium 620 #9359480 for sale

URL successfully copied!

Tap to zoom

ID: 9359480

Vintage: 2001

Automated epoxy dispenser

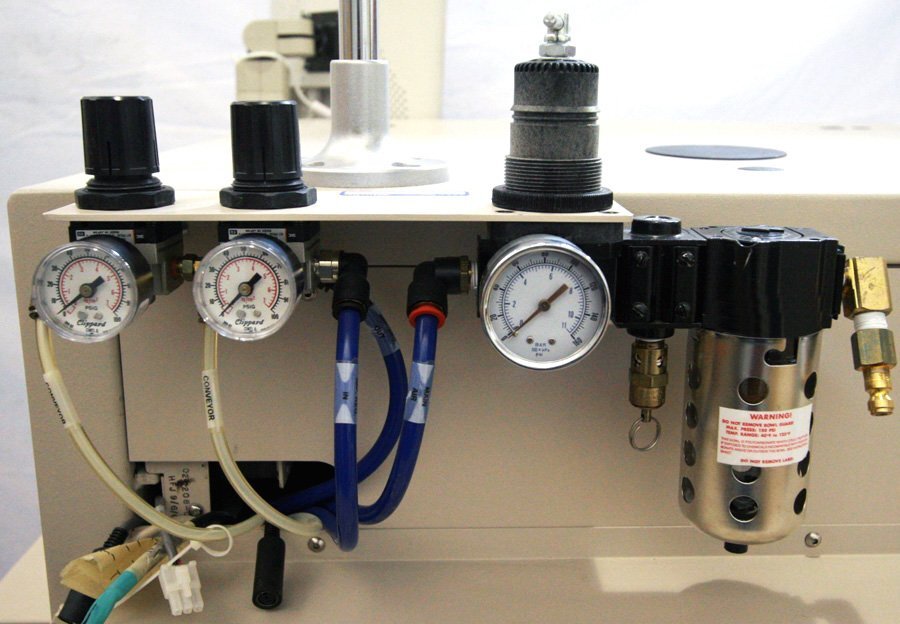

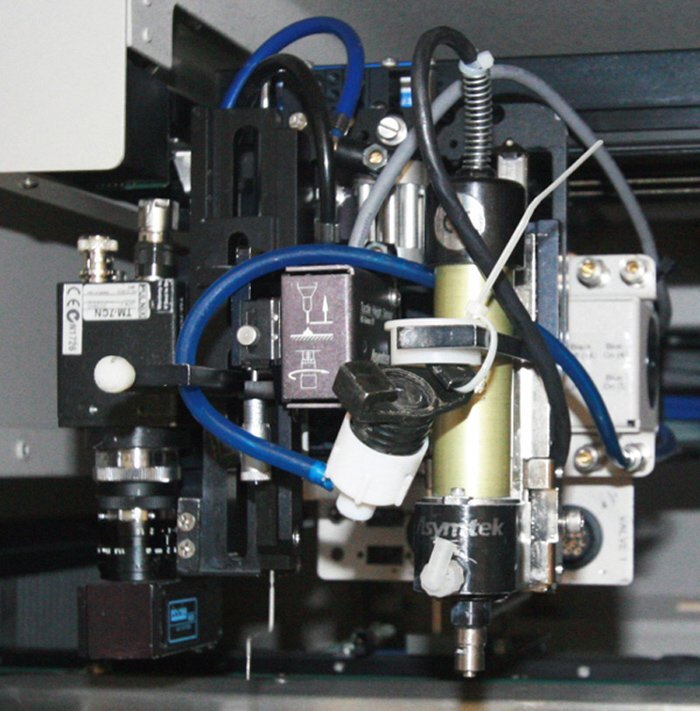

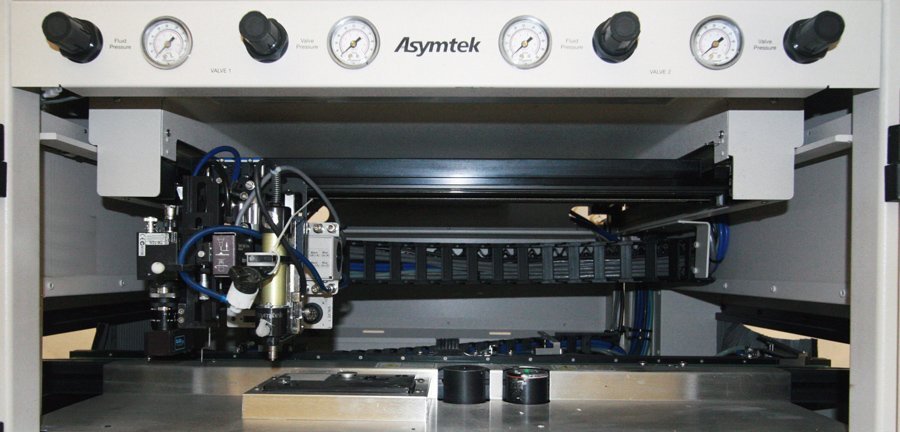

Dual dispense system with DV-6231 and DV-6331 pumps

Maximum Z travel: 89 mm

HS-Series RT tactile height sensor

PULNIX TM-7CN CCD Camera with LED ring light

DC Motor motion system

XY Velocity: 381 mm/s

System repeatability: ±0.025 mm

Positional accuracy: ±0.013

Dispense area: 355.5 mm x 269.1 mm

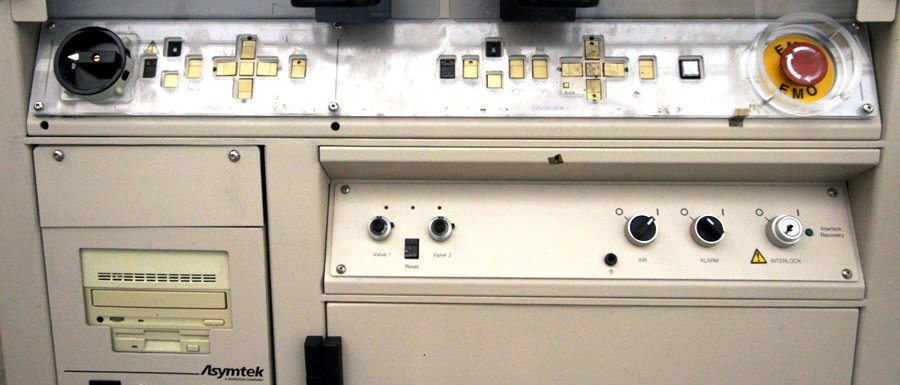

201D Dispense controller

201W Conveyor controller

4-Channels encapsulation module, P/N: 62-0738-00

Conveyor interface

PM-100 Power manager

TS-01 Input / Output control panel

Computer

Operating system: Microsoft NT 4.0

ITI Vision system with pattern recognition

Monitor and keyboard with trackball

Input power:

100/120 VAC, 47-62 Hz, Single phase

220/240 VAC, 47-62 Hz, Single phase

2001 vintage.

ASYMTEK Millennium 620 equipment is a set of automated solutions for printed circuit board (PCB) assembly and manufacturing. It is designed to increase productivity and reduce cost while providing quality assembly. Millennium 620 consists of several factors that contribute to its high level of performance. It includes a robust vision system to precisely and accurately locate and place components. This unit also offers component placement accuracy up to ±0.002 in (0.05mm), depending on the component being handled and a placement speed of up to 6,000 cph. It also features a high-end printed circuit board transport machine and high-quality camera optics for inspection and capturing images of each board position. The tool offers compatibility with a variety of components, including BGA, QFN, QFP, SIP, SMT, mixed technology, and odd form assemblies. It is also equipped with advanced placement and indexing capabilities, which allow for precise part alignment during board assembly. The asset uses a vacuum nozzle and manipulator to deliver complete x-y-z motion and placement accuracy. ASYMTEK Millennium 620 also offers several features that help ensure product quality. It has an integrated component verification model to make sure components are correctly placed. It is also equipped with an advanced hot-bar soldering equipment for reliable soldering performance. Overall, Millennium 620 is a powerful automated system that provides an efficient and cost-effective solution for PCB assembly and manufacturing. It offers a wide range of features, including a robust vision unit, high-end PCB transport machine, superior placement accuracy, advanced placement and indexing capabilities, and advanced component verification and soldering systems. All of these features make ASYMTEK Millennium 620 an ideal choice for many PCB assembly and manufacturing operations.

There are no reviews yet