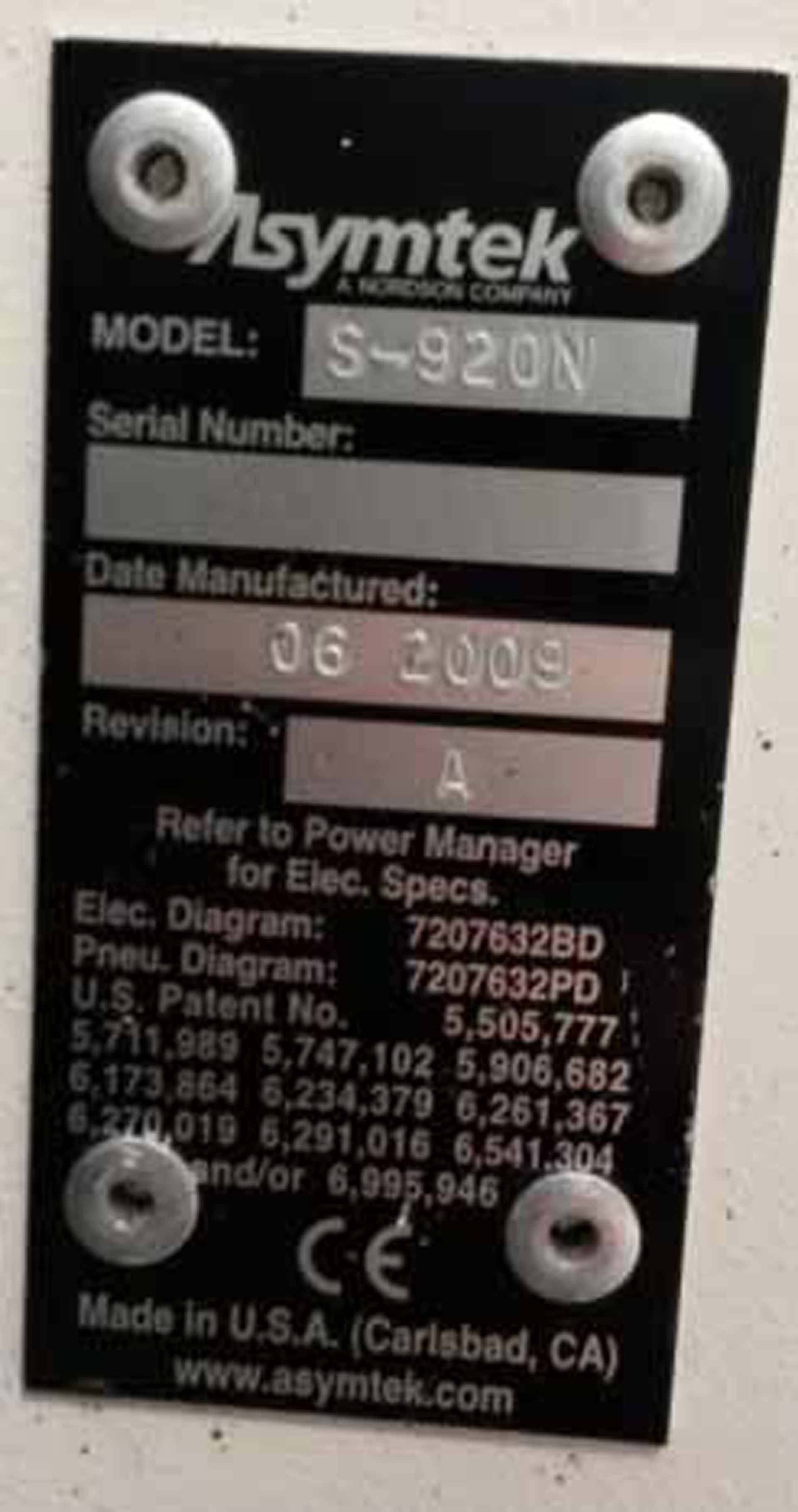

Used ASYMTEK S-920N #9240551 for sale

URL successfully copied!

Tap to zoom

ASYMTEK S-920N is a high-speed, precision dispense equipment designed for the assembly and manufacturing of printed circuit boards (PCBs). This system offers superior performance and is built to meet the requirements of high-volume production. It is equipped with a 150mm (6") per second servo motor drive, optics, and a 24.5" x 15.0" (620mm x 380mm) flat bed for superior control and accuracy in applications such as bead, underfill, paste, potting, HMV, die attachment and more. ASYMTEK S-920 N includes a pressure range of 0.5 to 40psi (0.034 to 2.76 Bars), a pressure accuracy of +/-0.005psi (0.00034Bars) and a temperature control range of 0°C to 70°C (32°F to 150°F). It offers fine-tuning of dispense parameters with its 0.1msec Single Drop Technique, allowing the repeatable placement of individual dabs from 1 to 300mg (0.01 to 0.17cc). S-920N is also fully programmable, allowing for easily repeatable programming sequences with the included TouchView Human Machine Interface (HMI). In addition, S-920 N includes selective vision techniques, such as integrated vision systems, to ensure precise placement such as spot adjust and teach box. The vision unit has line scan, edge detect, and pattern match algorithms, as well as barcode reading/decoding. With optional components and accessories such as a conveyor, blanking machine and temperature controllers, ASYMTEK S-920N can be configured to meet the needs of almost any assembly and manufacturing process. ASYMTEK S-920 N's high-resolution, mounted optics increase throughput and accuracy while minimizing operator fatigue and downtime. The tool is both easy to use and compact, making it ideal for use in high-volume manufacturing environments. S-920N is backed by ASYMTEK, the leader in precision dispensing, to provide customers with the support they need to meet their goals. S-920 N is a reliable and cost-effective addition to any production line.

There are no reviews yet