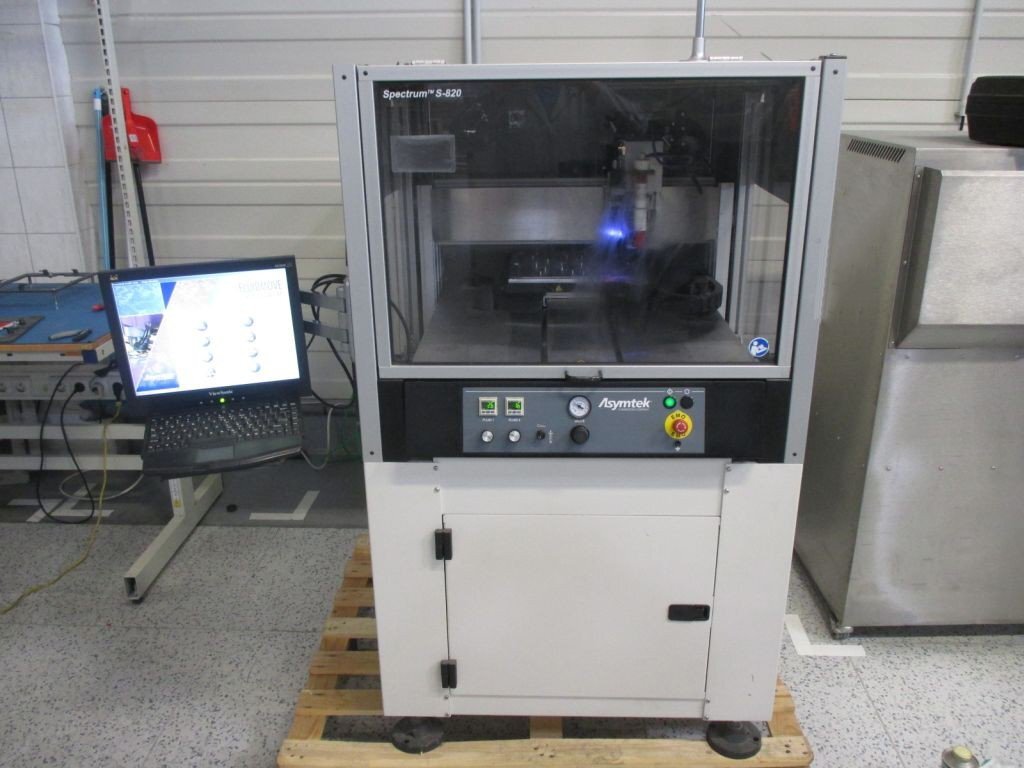

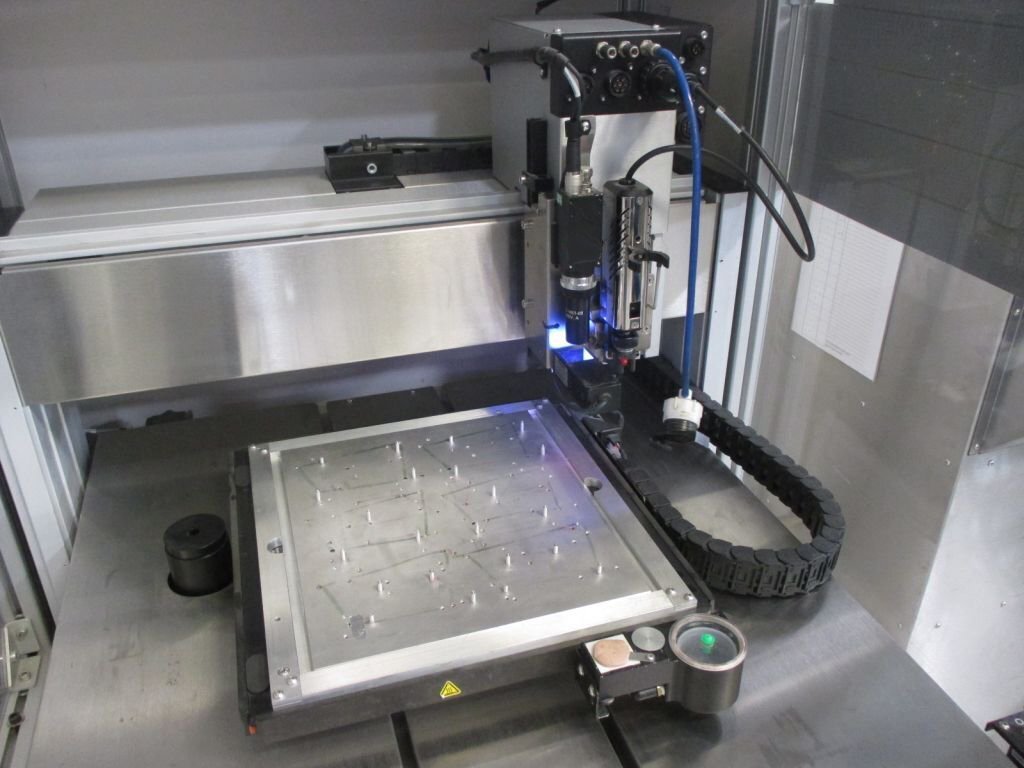

Used ASYMTEK Spectrum S-820 #191044 for sale

URL successfully copied!

Tap to zoom

ID: 191044

Vintage: 2007

Dispenser

Features:

Advanced process control modules:

Mass Flow Calibration (MFC)

Calibrated Process Jetting (CPJ)

Dynamic Dispense Control (DDC)

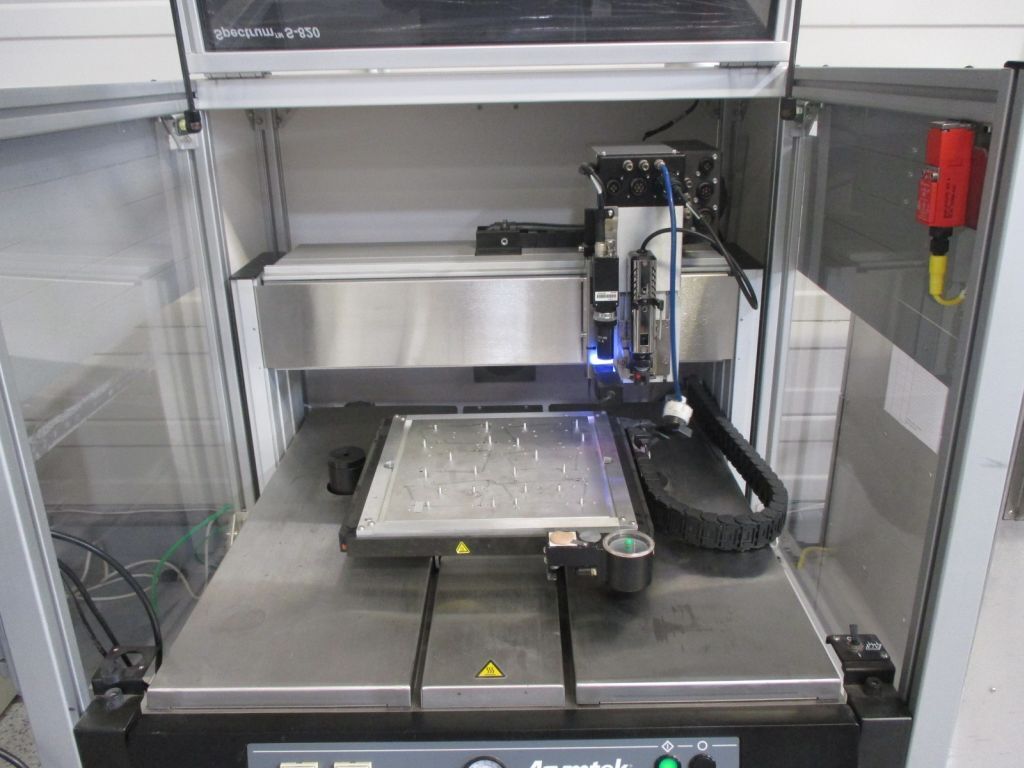

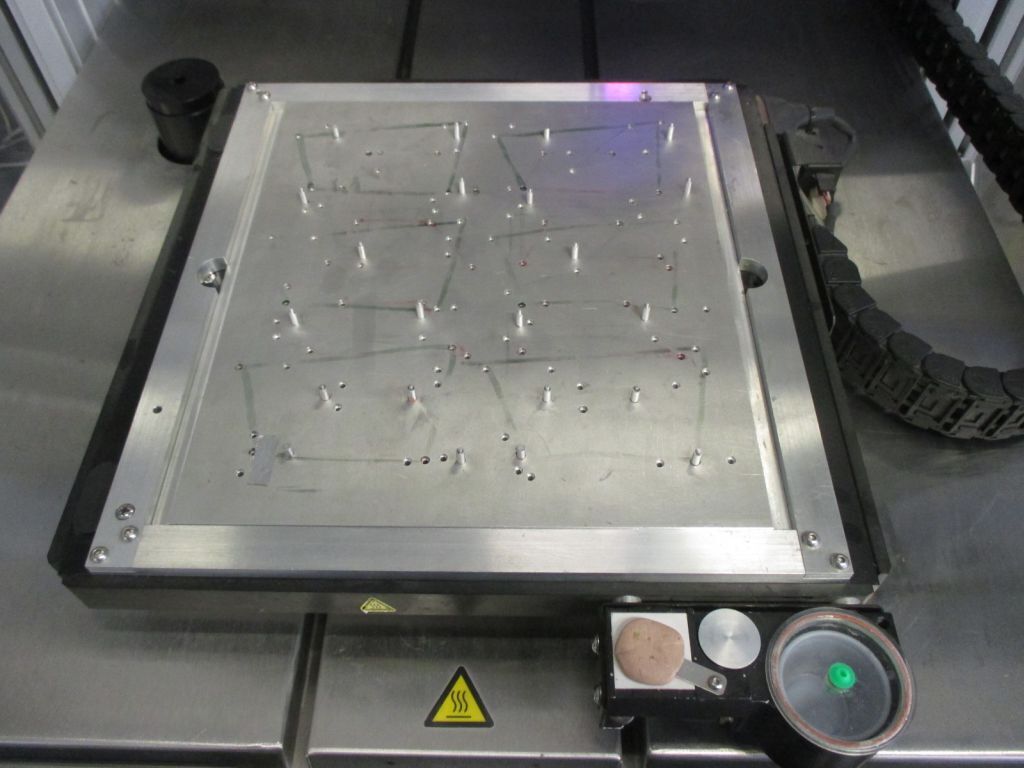

Heated vacuum tooling plate with programmable set points: 350 mm x 350 mm

Light beacon with audible alarm

Low air pressure alarm with programmable set point

Mechanical tactile height sensor

Needle heater control with programmable set points

Precision air regulators

Vacuum purge station

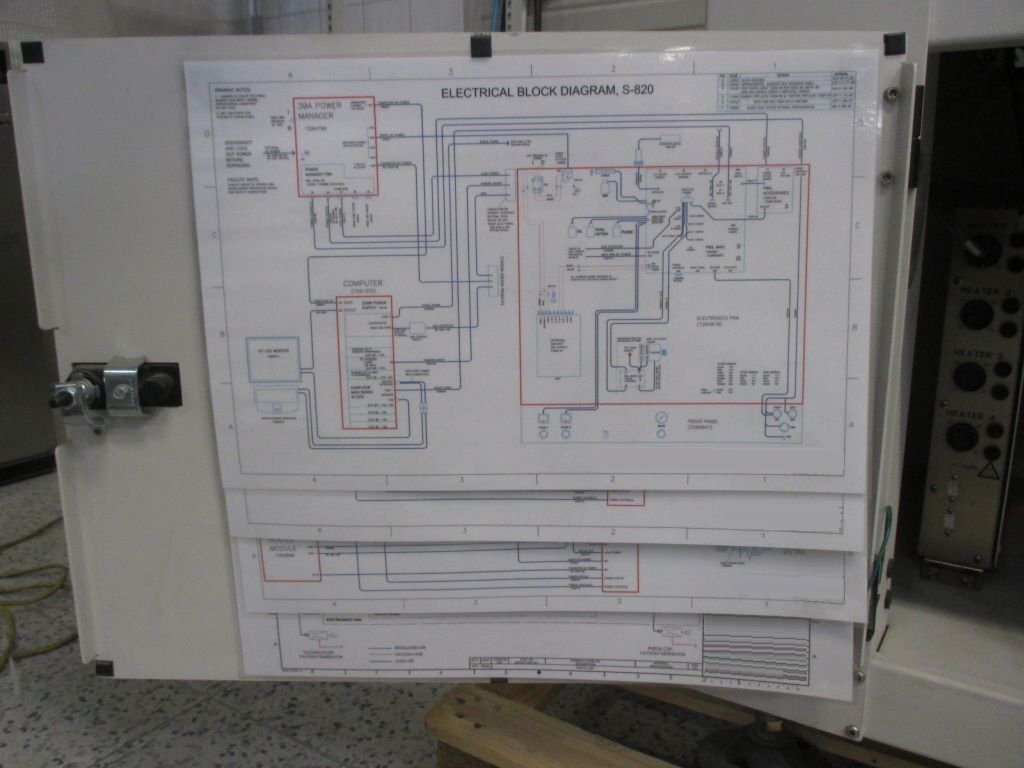

Motion system:

Type: Brush less DC servo motors, closed-loop encoder feedback

X-Y Velocity: 500 mm/s maximum

Z-Axis velocity: 500 mm/s maximum

X-Y Repeatability: ±0.025 mm (0.001")

Z-Axis repeatability: ±0.025 mm (0.001")

X-Y-Z Resolution: 0.010 mm (0.0004")

Positional accuracy: ±0.075 mm (0.003")

Vision and lighting:

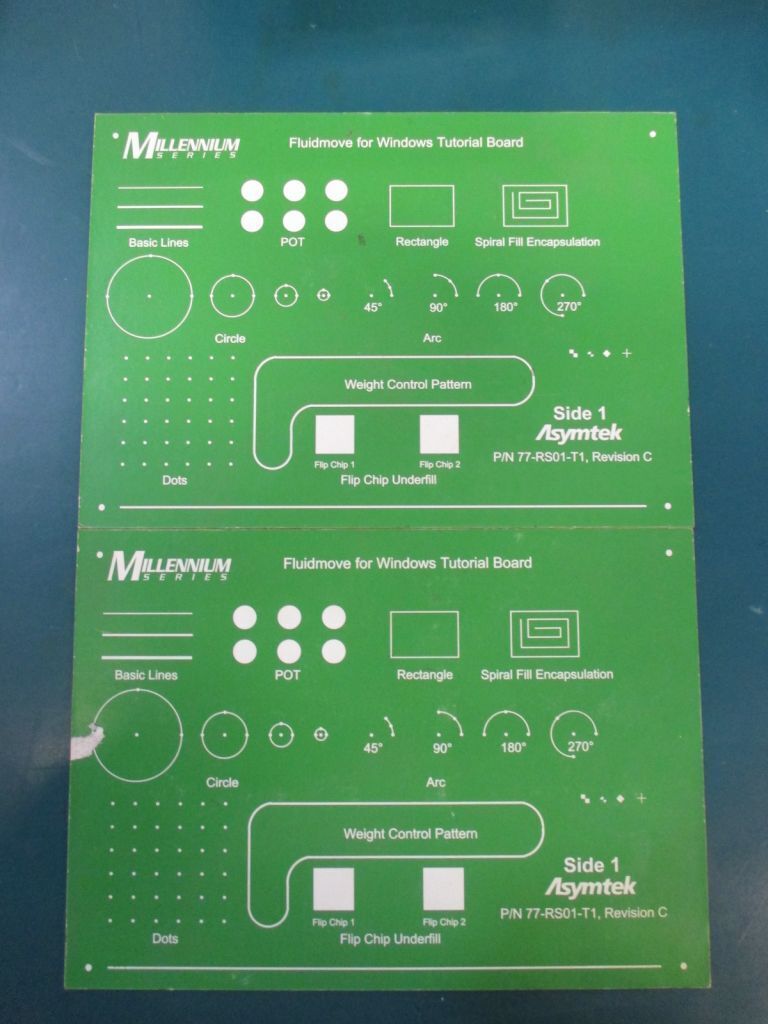

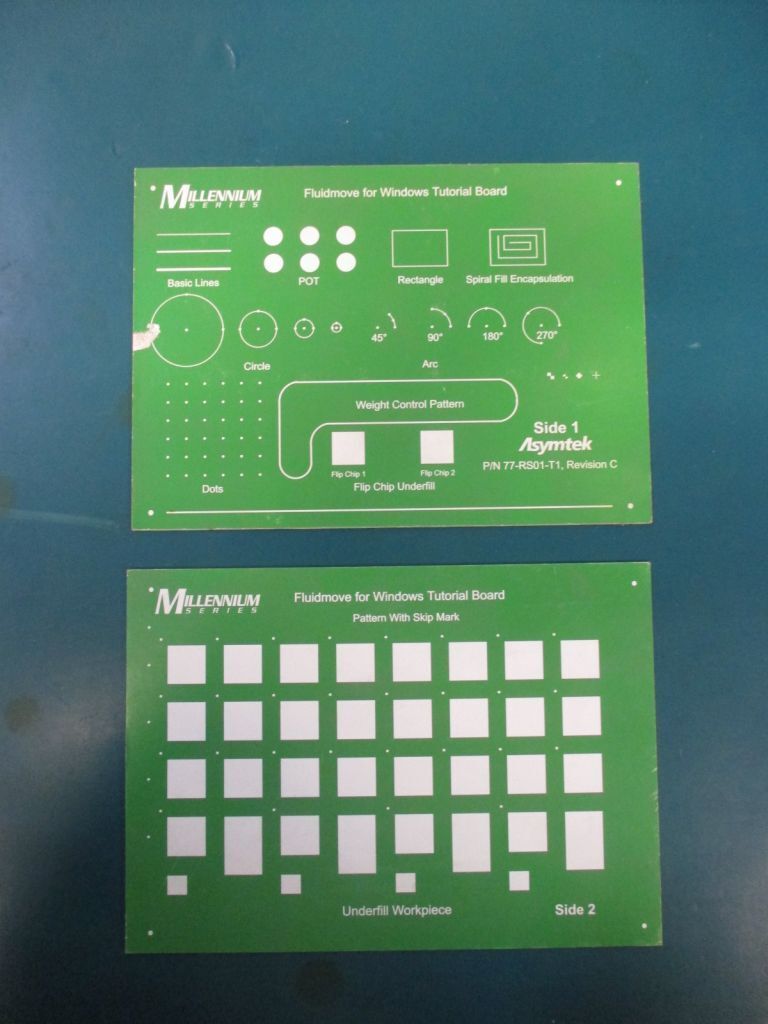

Vision system with automatic pattern recognition

Image size: 6 mm (0.25") standard

Programmable lighting

Red / Blue LED

Light levels: 255 Steps

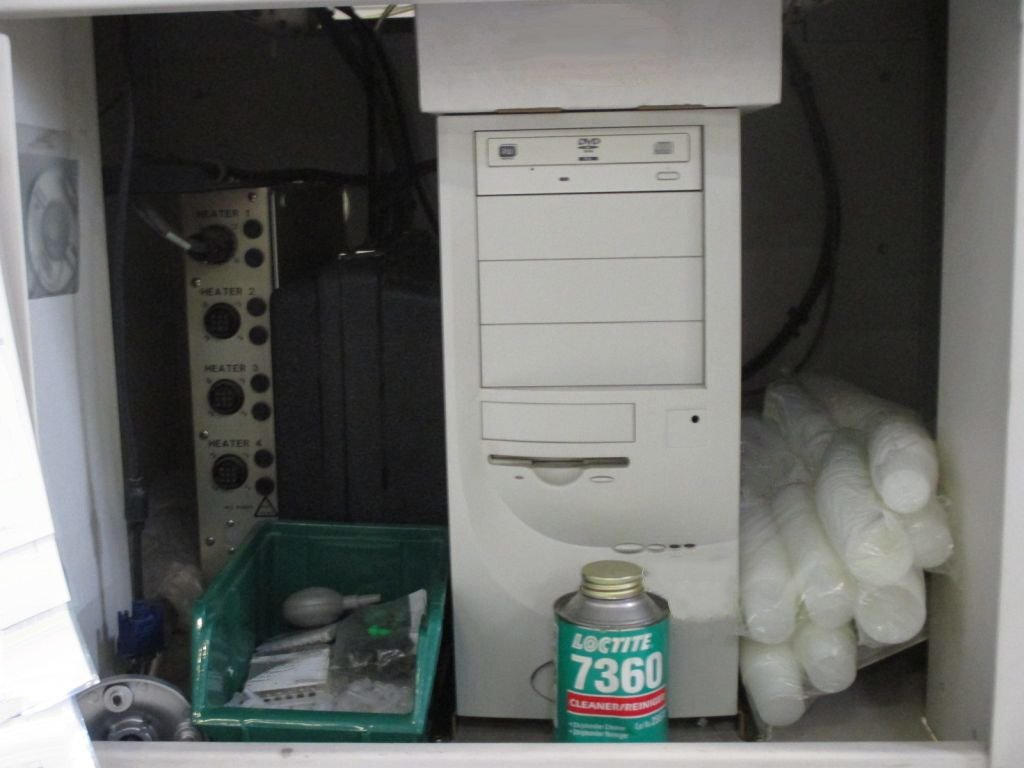

Computer:

Windows-based PC with 3.5" (1.44 MB) floppy and DVD-RW drives

User interface:

Color LCD flat-panel display

ASCII Keyboard

Touch pad

Ethernet network port

Front and rear USB ports

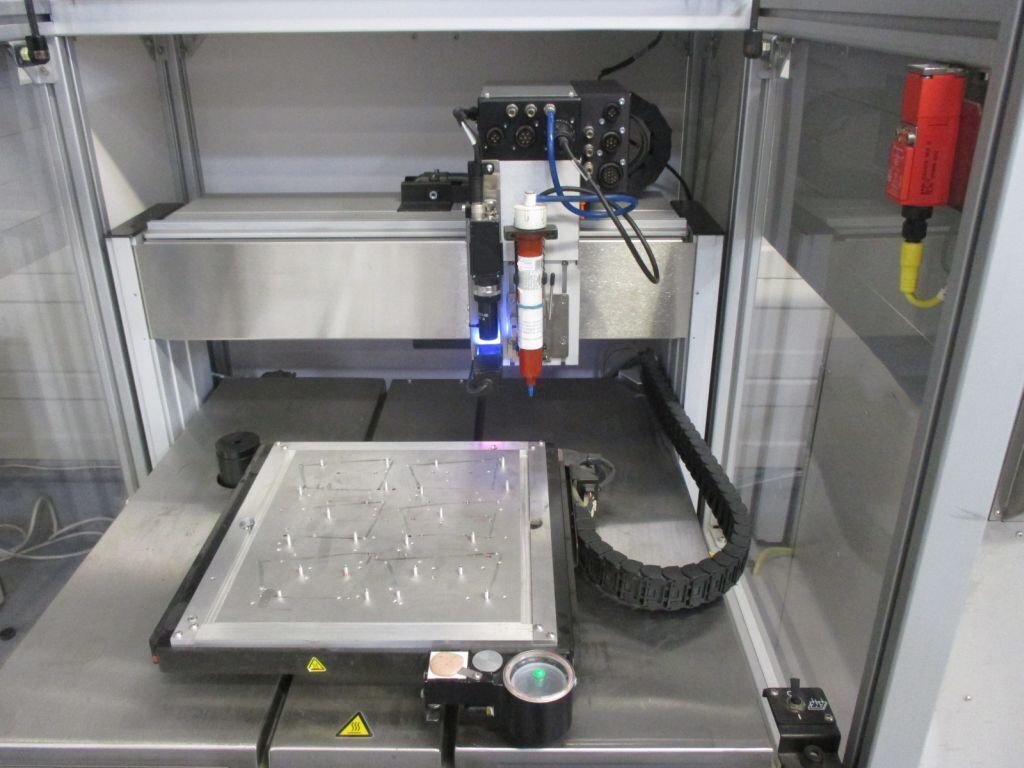

Fluid delivery method:

DispenseJet DJ-9000

Heli-flow DV-7000

Heli-flow DV-8000 Auger pumps

DV-01

DV-02

DV-03

DV-05

DV-07

DV-09

Energy consumption:

Idle: 325 W

Average: 375 W

Peak: 925 W (Peak value depends on AC input voltage)

AIC Interrupt capacity: 10 kA

Audible noise level: 67 dB(A)

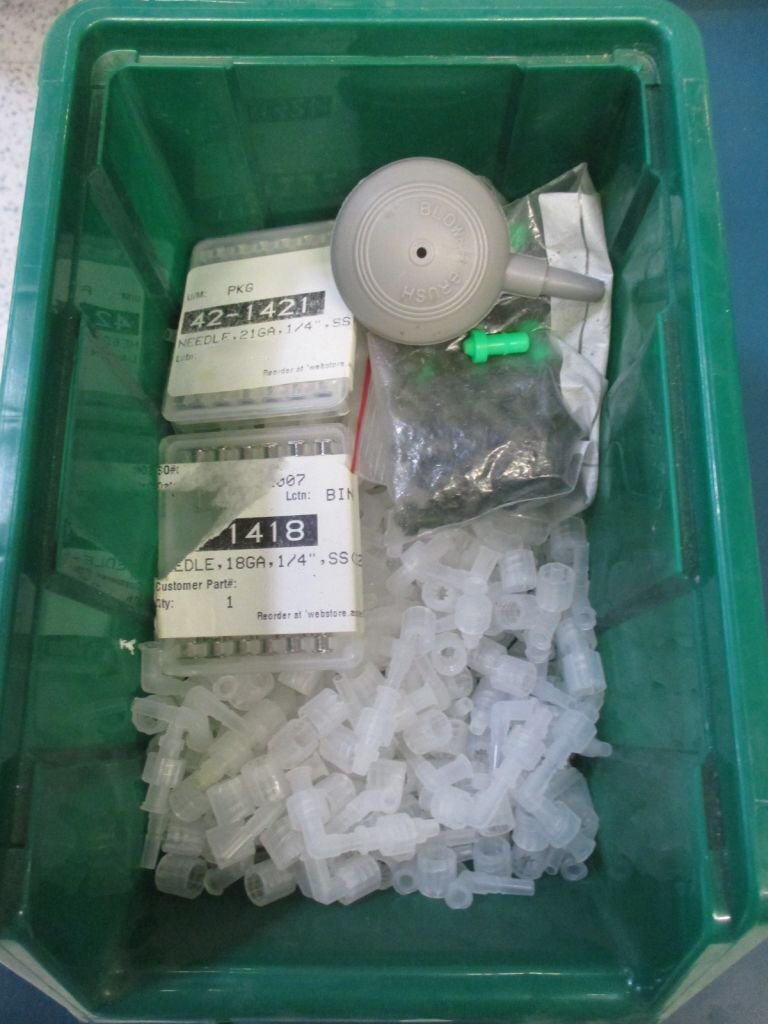

Options:

Impingement tooling

Dual-action dispensing head

Laser height sensor

Low fluid sensor

Needle heater

SECS/GEM Interface

Integrated height sensor:

Weigh station

Heated tooling plate

2007 vintage.

ASYMTEK Spectrum S-820 is a fully automated PC board assembly and manufacturing equipment. This system is designed with the goal of making component placement and assembly processes faster and more reliable. With its industry-leading performance, Spectrum S-820 is ideal for many medium- to high-volume applications. This unit features a high-precision tooling machine that guarantees accurate component placement and a robust control platform. It offers the flexibility of a modular design, while also providing users with advanced vision and verification systems to ensure component placement and assembly accuracy. To further optimize placement, the tool also comes with a variety of software options. In addition to a choice of several different SMT head options, the board assembly station can be customized to suit individual applications. It also has an integrated board support asset that improves accuracy and ensures that the board does not move between process steps. ASYMTEK Spectrum S-820 contains a high-speed magazine feeder that quickly and accurately loads and unloads components. It is fitted with multiple nozzle stations for high placement speeds and an advanced vision model to quickly detect component placement errors. Additionally, the machine includes a powerful component recognition equipment, allowing for the easy placement of difficult components. In terms of process control, Spectrum S-820 is equipped with an array of advanced features including host PC integration, real-time performance monitoring, and control of automated processes. The system is compatible with a wide variety of software solutions for data collection and analysis allowing users to quickly access up-to-date production information. Overall, ASYMTEK Spectrum S-820 is a powerful, reliable, and versatile PC board assembly and manufacturing unit that offers superior performance. Whether for high-volume production or small batches, Spectrum S-820 is a great choice for reliable and accurate component placement and assembly.

There are no reviews yet