Used ASYMTEK TC 3000 #9059466 for sale

URL successfully copied!

Tap to zoom

ID: 9059466

IR/Convection module

Includes:

Windows user interface

Individual heating zones (programmable)

SMEMA-compatible conveyor

Multi-language user interface

Light beacon

Touch screen

Specifications:

Number of heating zones: 6

Heating length: 118"

Exhaust requirements: 647 CFM

Thermal environment:

Maximum process temperature: 250º C

Process profile repeatability: +/- 5º C

Heat-up time: 30 min. (includes stabilization)

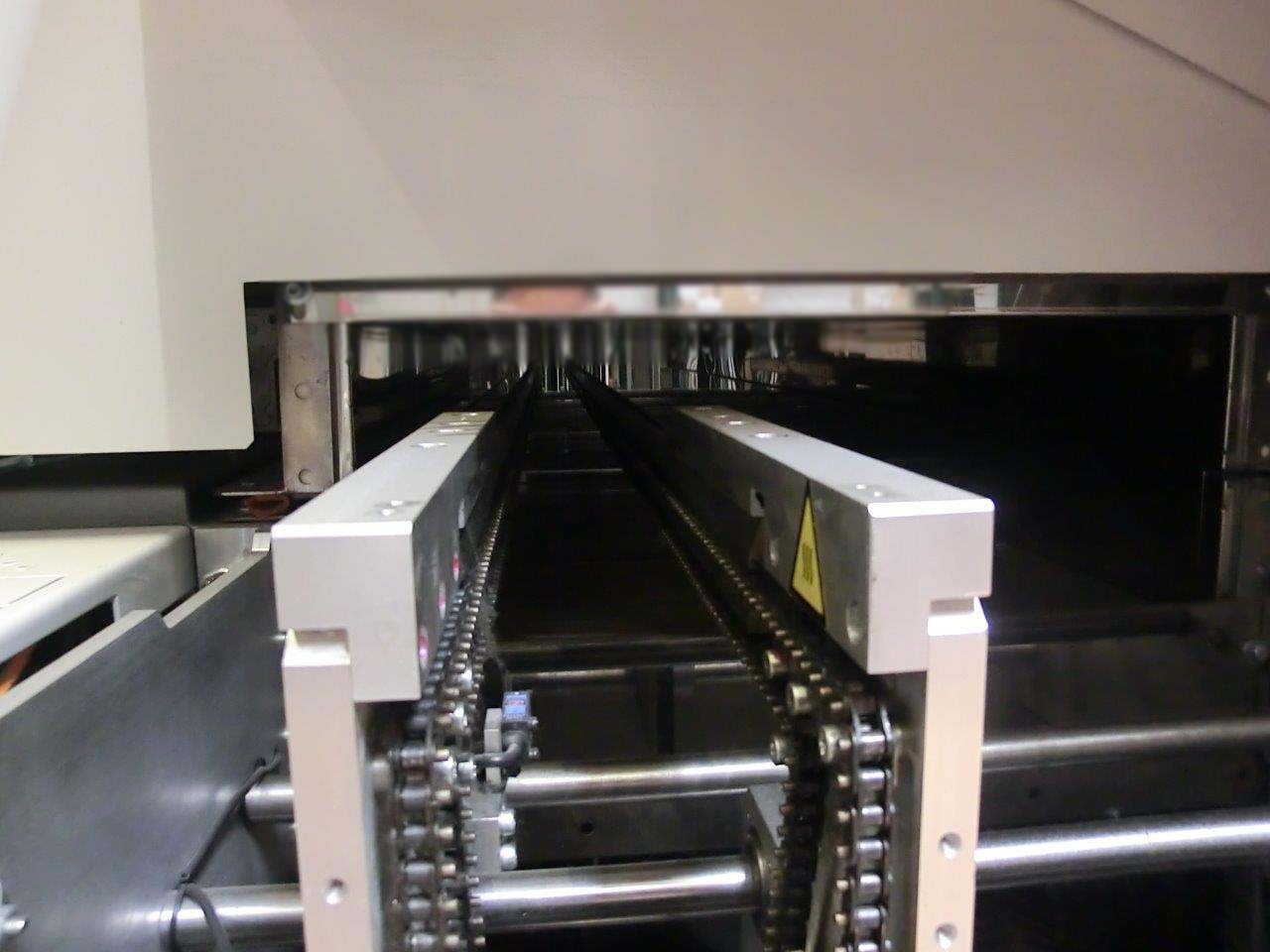

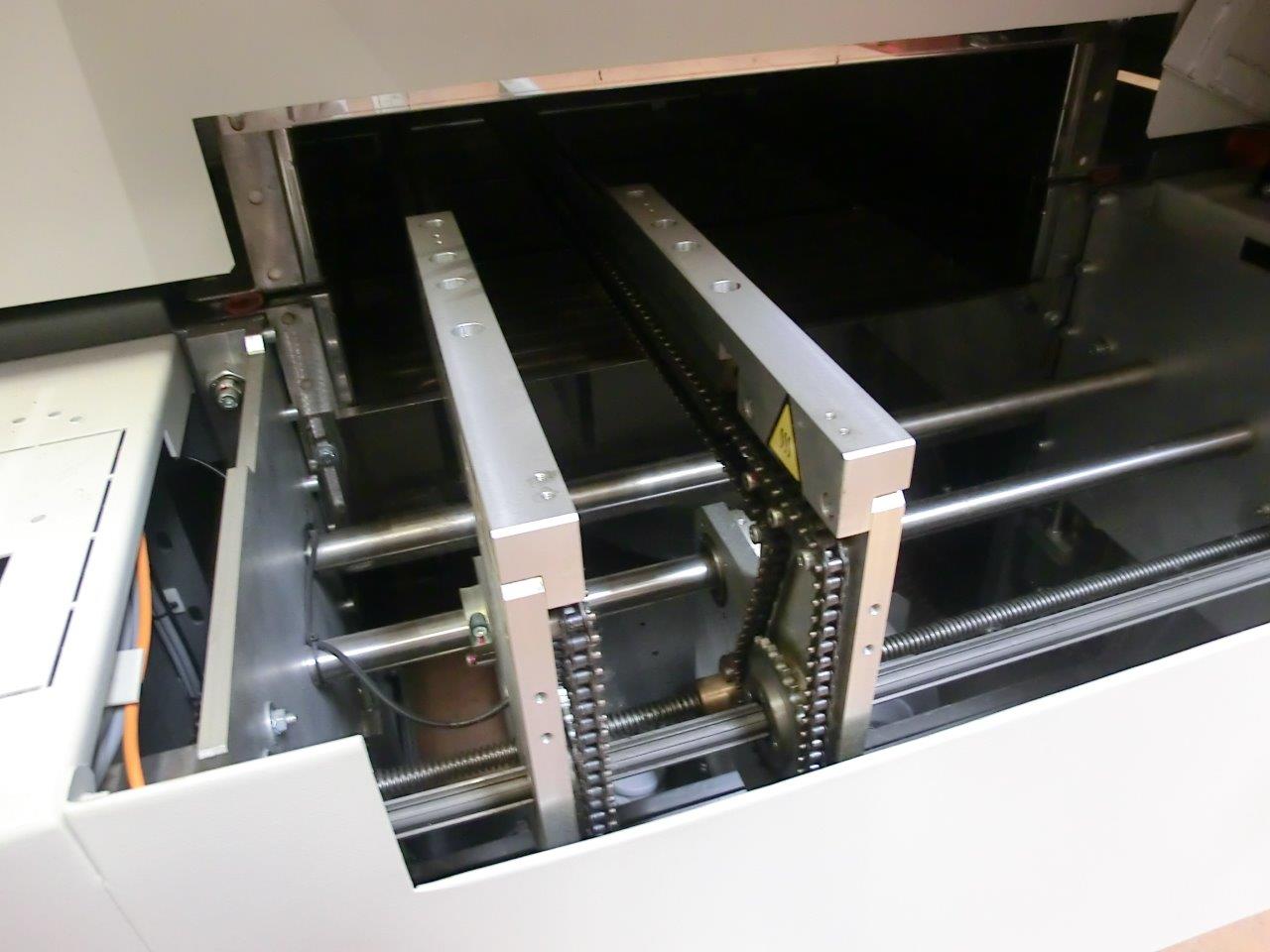

Conveyor:

Board width: 2" to 18"

Board clearance: 3.9"

Standard speed: 6.5 to 32.5 in/min

Pin/chain conveyor: 0.2"

Conveyor height: 35.4" to 38.6"

CE-Marked

400 VAC, 3-Phase, 5 wire, 38 kW

2007 vintage.

ASYMTEK TC 3000 is a pc board assembly and manufacturing equipment designed to meet the needs of aerospace, defense, medical, and other industries requiring high-quality production. TC 3000 system includes a four-axis high-performance motion controller and patented, high-speed linear servo motors, providing reliable and accurate motion control for automated assembly, dispensing, and soldering operations. The unit also includes a computer workstation for process monitoring, automation, and control. The workstation is capable of controlling multiple systems simultaneously, and the control software accommodates multiple applications, including PCB assembly and rework, radiation hardened components, and the minimization of fiducial error. The workstation is programmed in ASYMTEK proprietary software language, providing easy command and parameter configurations. ASYMTEK TC 3000 also features a retractable column design with dual linear rails, providing a robust and rigid platform for precise and precise adhesive dispensing and soldering. The machine is capable of handling various substrates up to a maximum board size of 400mm (15.75in). Unique heat-balancing "easy-change" nozzles provide a precise solution to repetitive thermal stimulation for precise adhesive dispensing, wave soldering, and force-dispensing applications. The extended nozzle travel, temperature selection, and intuitive control software facilitates a wide range of application solutions. TC 3000 also features quick-change timed nozzles, intelligent closed-loop feedback, and internal vacuum ready for external connection. Safety features include dedicated torque shut-off for every motor in the tool, preventing it from causing any damage to the PCB while ensuring optimal process speed. The nozzles on ASYMTEK TC 3000 can be quickly changed to different shapes and sizes to accommodate components with varying size and specifications. TC 3000 is also compatible with all major automation electronics, including barcode readers, 4D vision sensors, liquid level sensors, grinding and polishing systems, RFID sensors, and various other sensors. ASYMTEK also offers a wide range of accessories to facilitate automation and optimise the asset performance, such as metal detectors, lamination systems, and adaptive fiducial recognition. ASYMTEK TC 3000 provides a solution that meets the needs of a wide range of industries and is designed to increase production throughput while maintaining product quality. It is designed with an intuitive graphical user interface (GUI), allowing users to monitor and control process parameters quickly and efficiently. Additionally, TC 3000 provides diagnostic and troubleshooting tools to identify and solve any problems that may arise.

There are no reviews yet