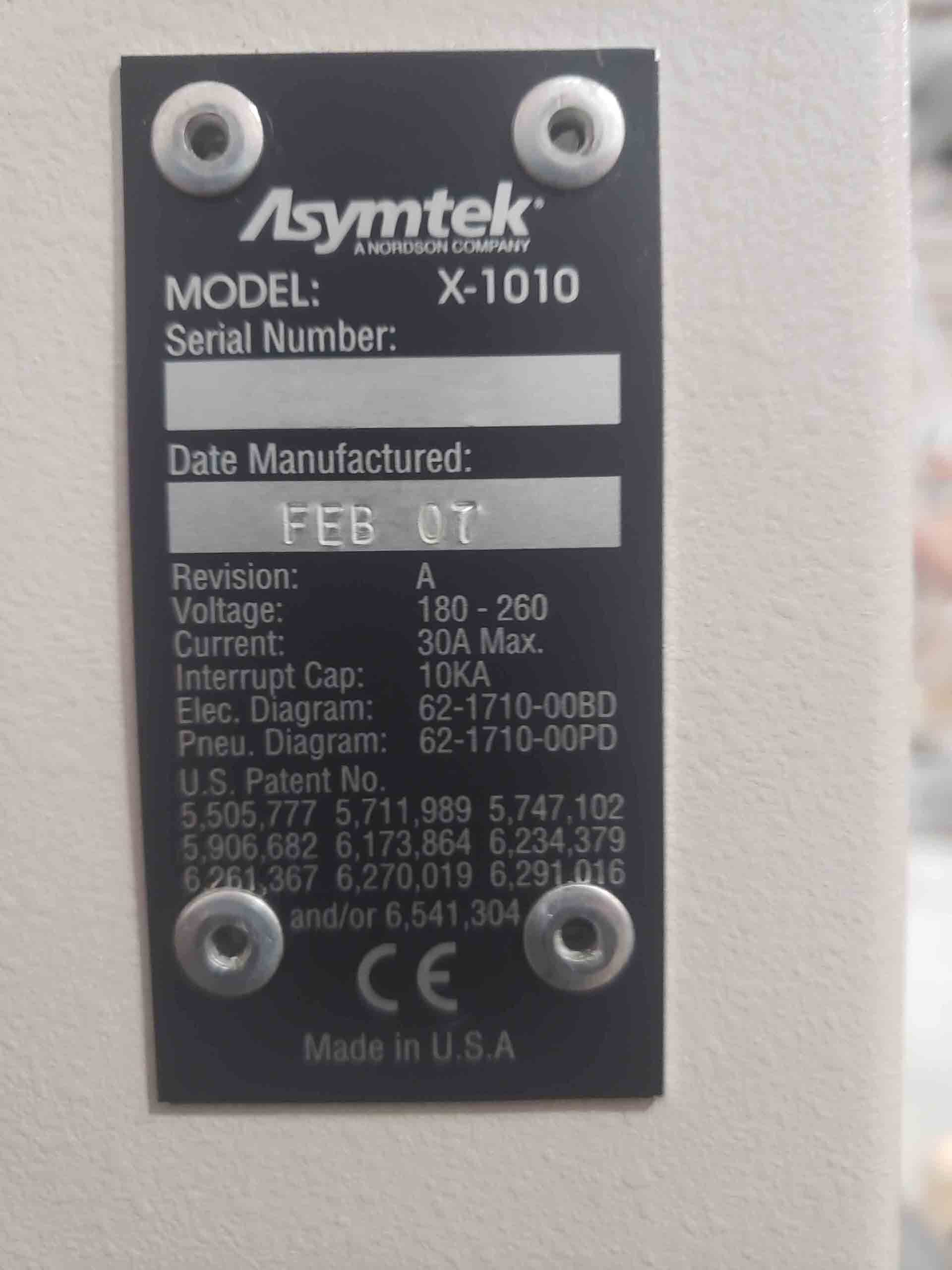

Used ASYMTEK X-1010 #9396089 for sale

URL successfully copied!

Tap to zoom

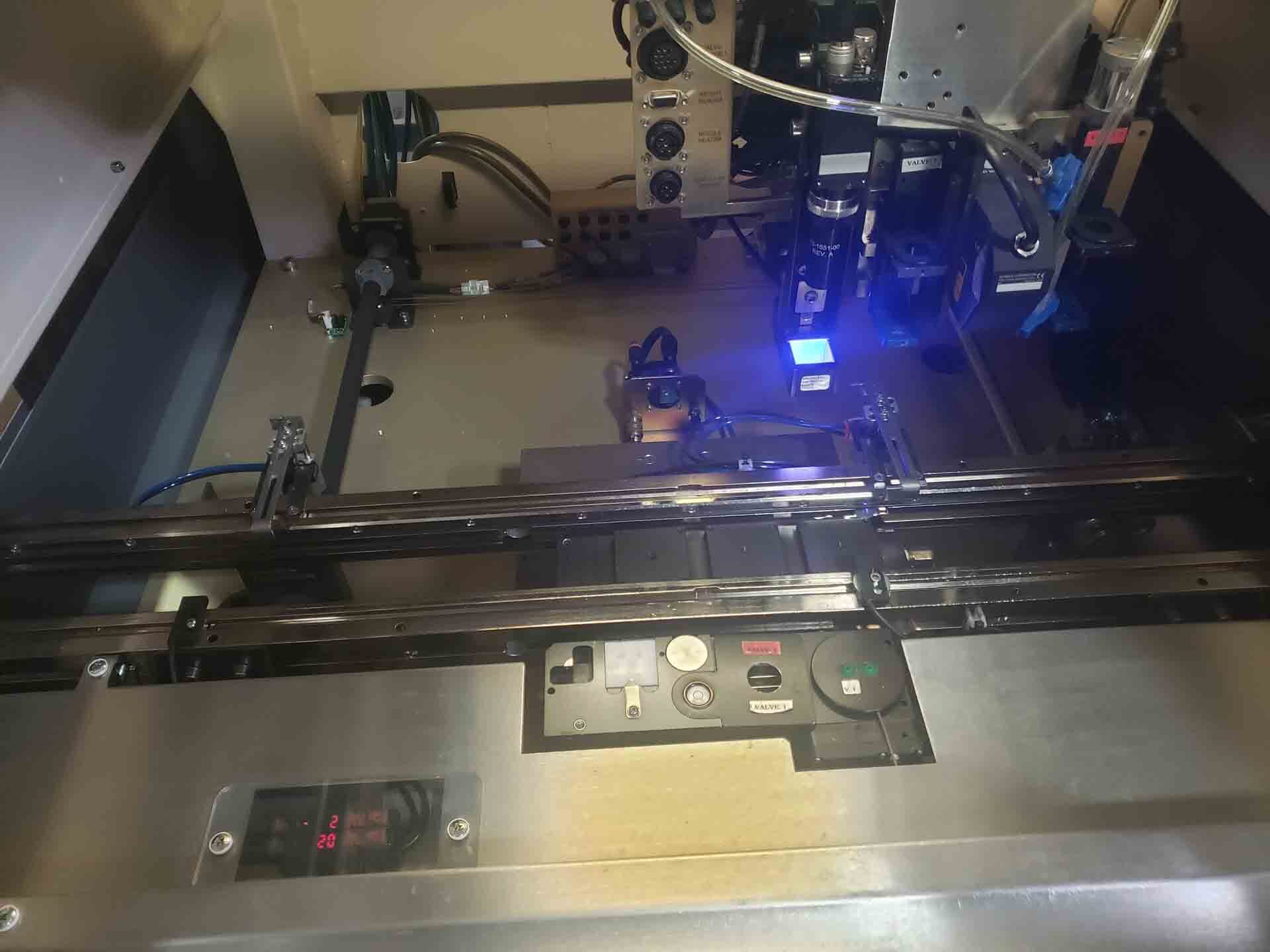

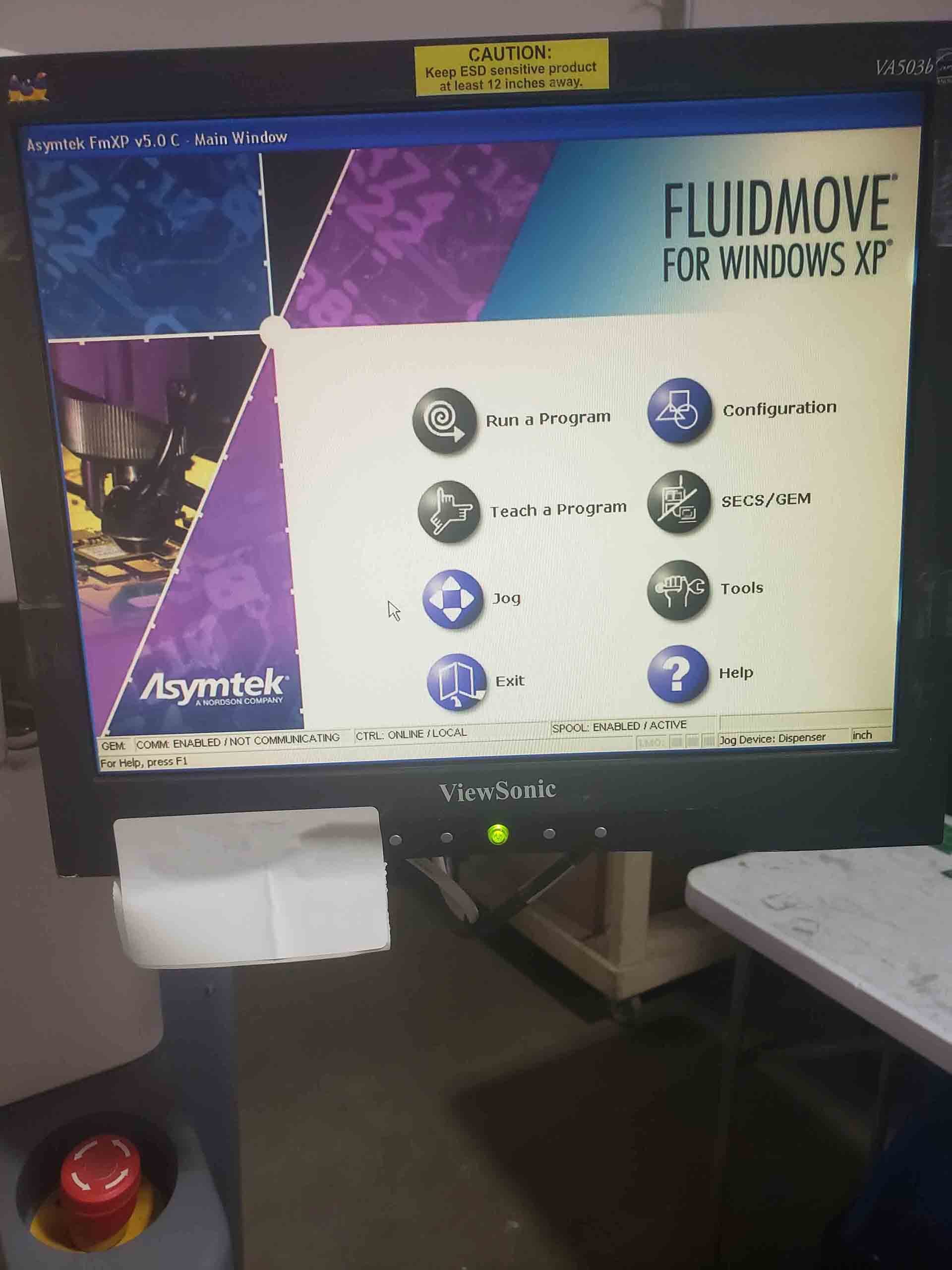

ASYMTEK X-1010 is a desktop-based pick and place machine designed to provide fast throughput for board assembly and manufacturing. It combines ease of use with next-generation machine technolog for great consistency and accuracy in assembly and manufacturing processes. ASYMTEK X 1010 features precision active assembly technology to provide excellent speed and accuracy in the placement of components, while the optics equipment enables reliable imaging and placement of components. X-1010 is designed to reduce manufacturing time, with its high rate of throughput and flexibility for various applications. The machine is equipped with both single and dual-head nozzles for optimal placement of various board sizes. The specially designed end-of-arm tooling allows for precise placement of components and provides increased speed and accuracy in device assembly and reworking. X 1010 is powered by a Windows-based computer system and includes a custom configured vision unit, allowing users to easily produce placement programs. This machine also features a powerful processor, allowing for a maximum speed of 1,200 parts per second. The machine also includes a high-resolution camera machine which enables accurate vision alignment for component placement and recognition. The automated vision programming is designed to save time in both the programming and part placement stages. ASYMTEK X-1010 has a wide range of uses as it is capable of multilayer module assembly, leaded component placement, and inspection capabilities. It has the capability to place components on both sides of the board and includes an optional multi-axis programming platform, allowing for custom programming of the components during the placement process. ASYMTEK X 1010 has a compact design and provides an efficient working environment with its enclosed workspace. The workspace includes both automatic conveyor systems and manual loading units for easy loading of components. It also provides easy access to the nozzle and board handling tool for maintenance and inspection. X-1010 is an advanced and reliable tool for board assembly and manufacturing, offering reliable automated assembly and precision and placement accuracy for various applications. With its integrated vision asset, advanced processor, and optics model, X 1010 provides a cost effective means for users to save time and improve accuracy in their assembly and manufacturing processes.

There are no reviews yet