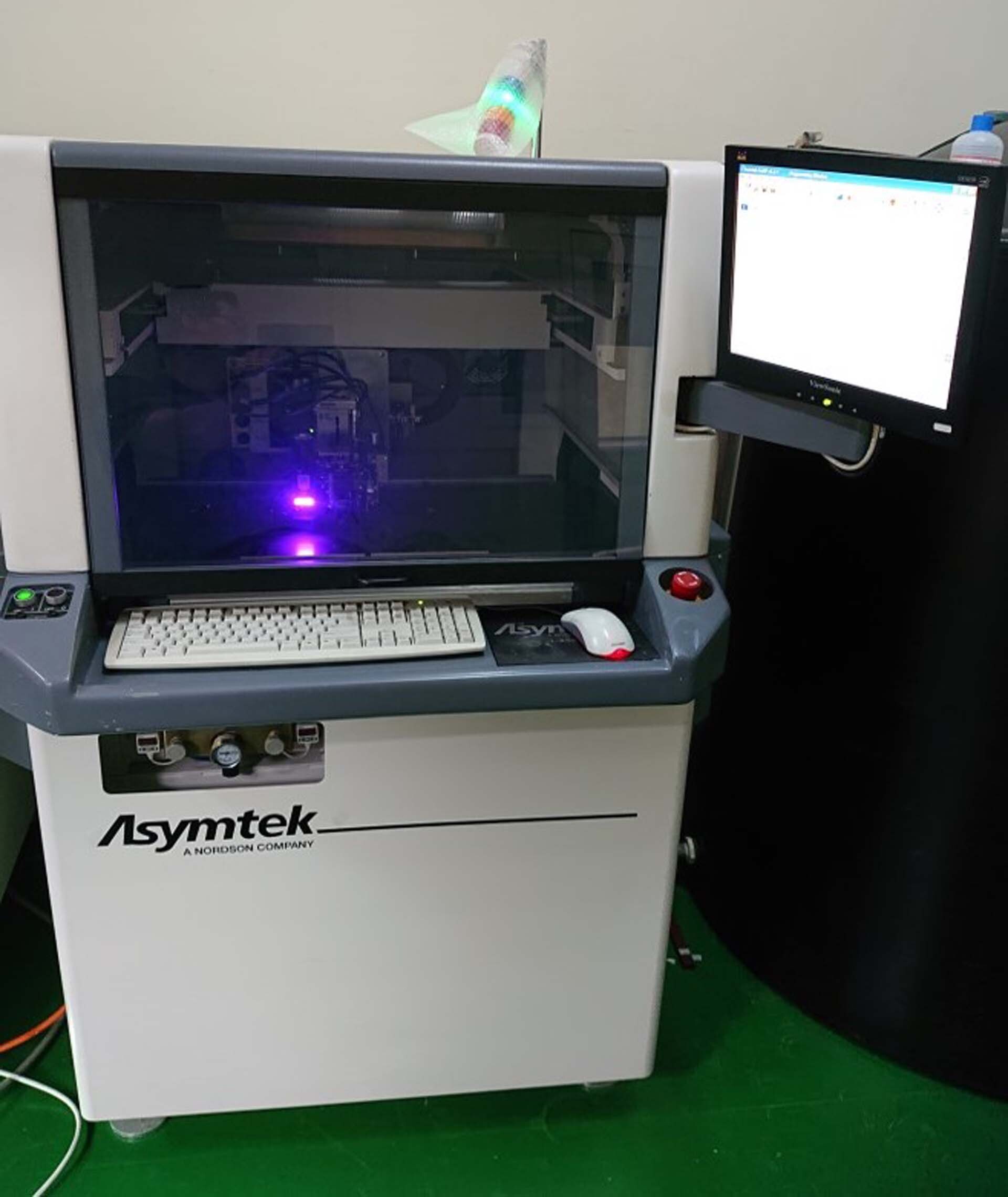

Used ASYMTEK X-1010 #9407897 for sale

URL successfully copied!

Tap to zoom

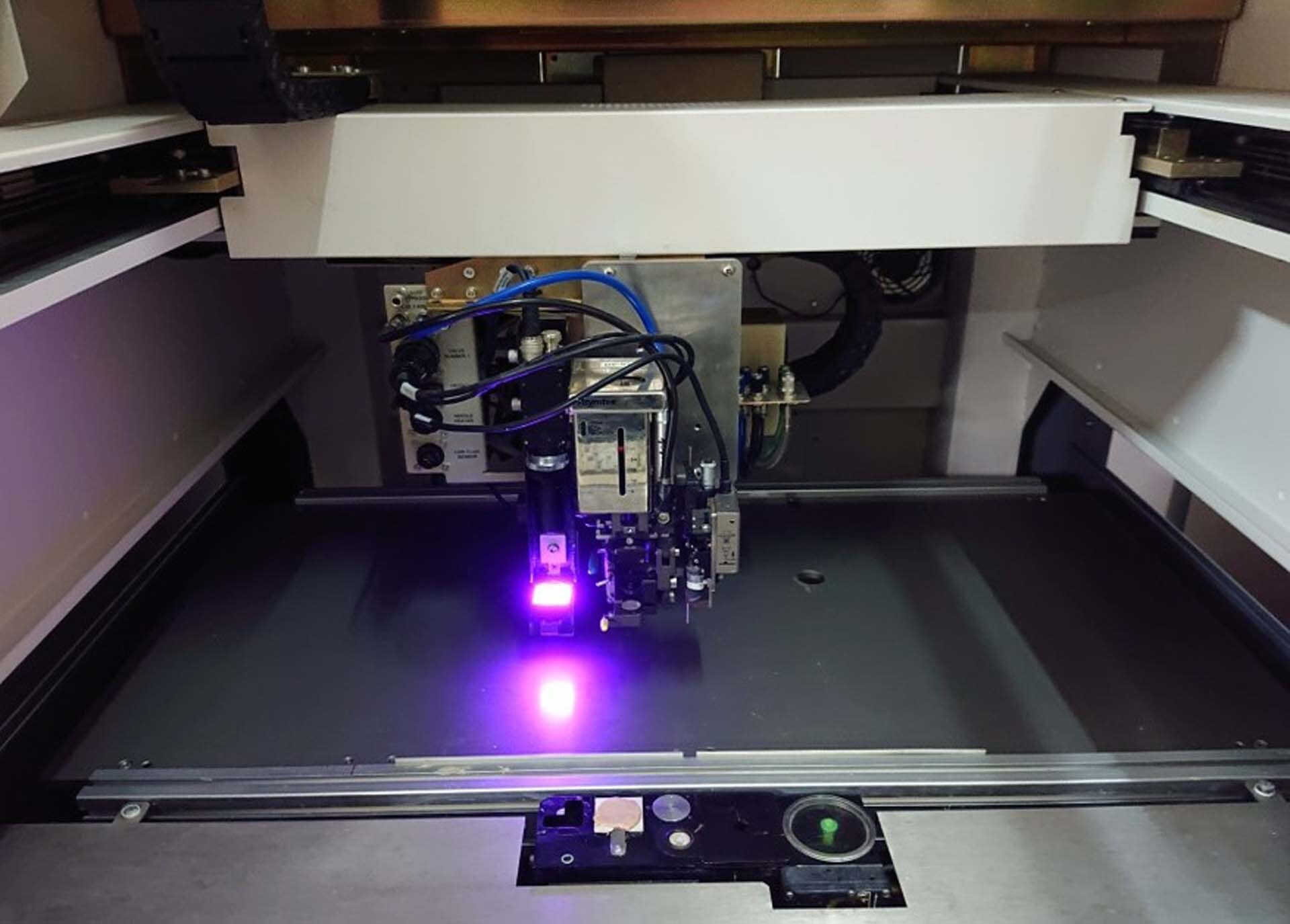

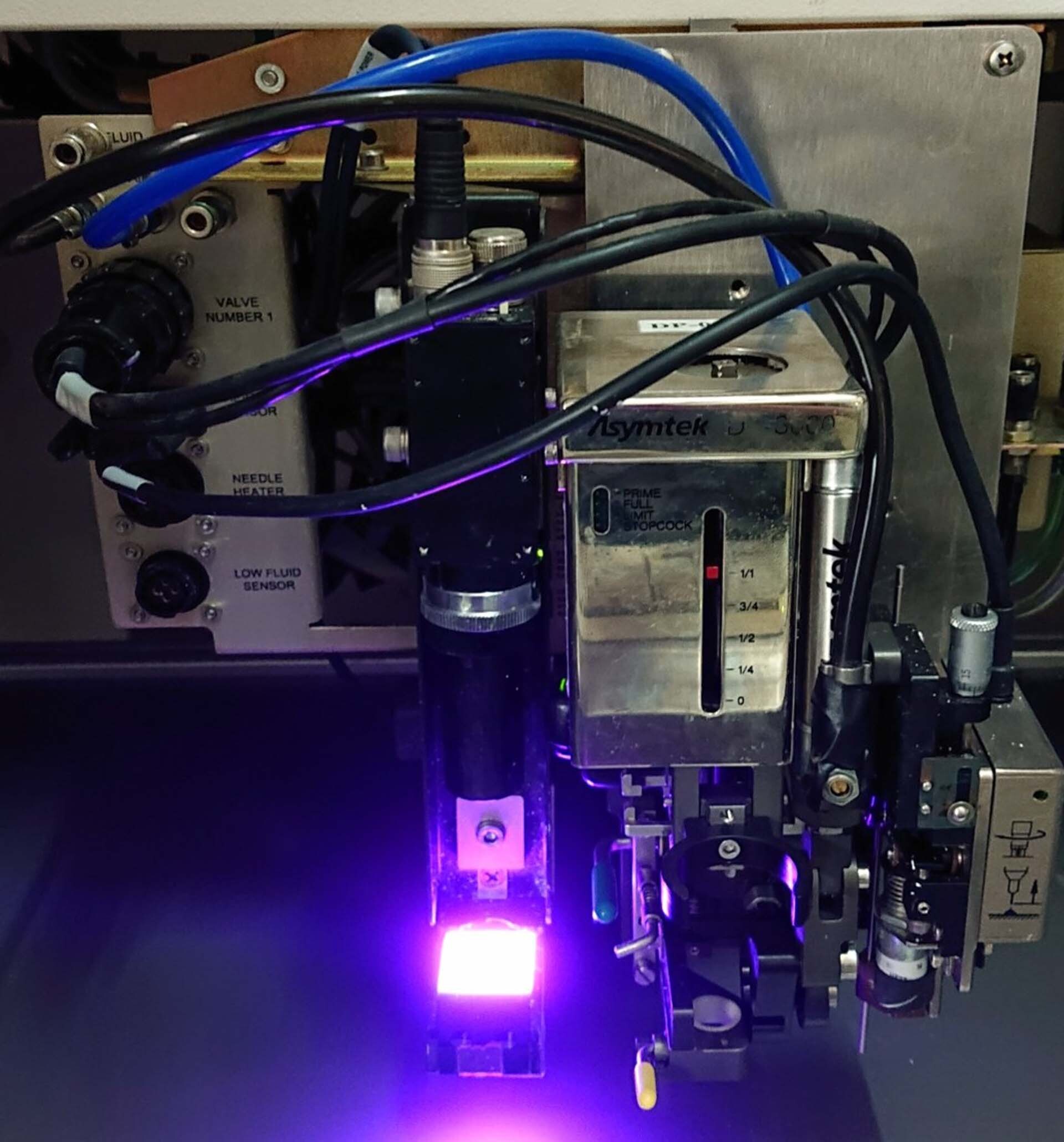

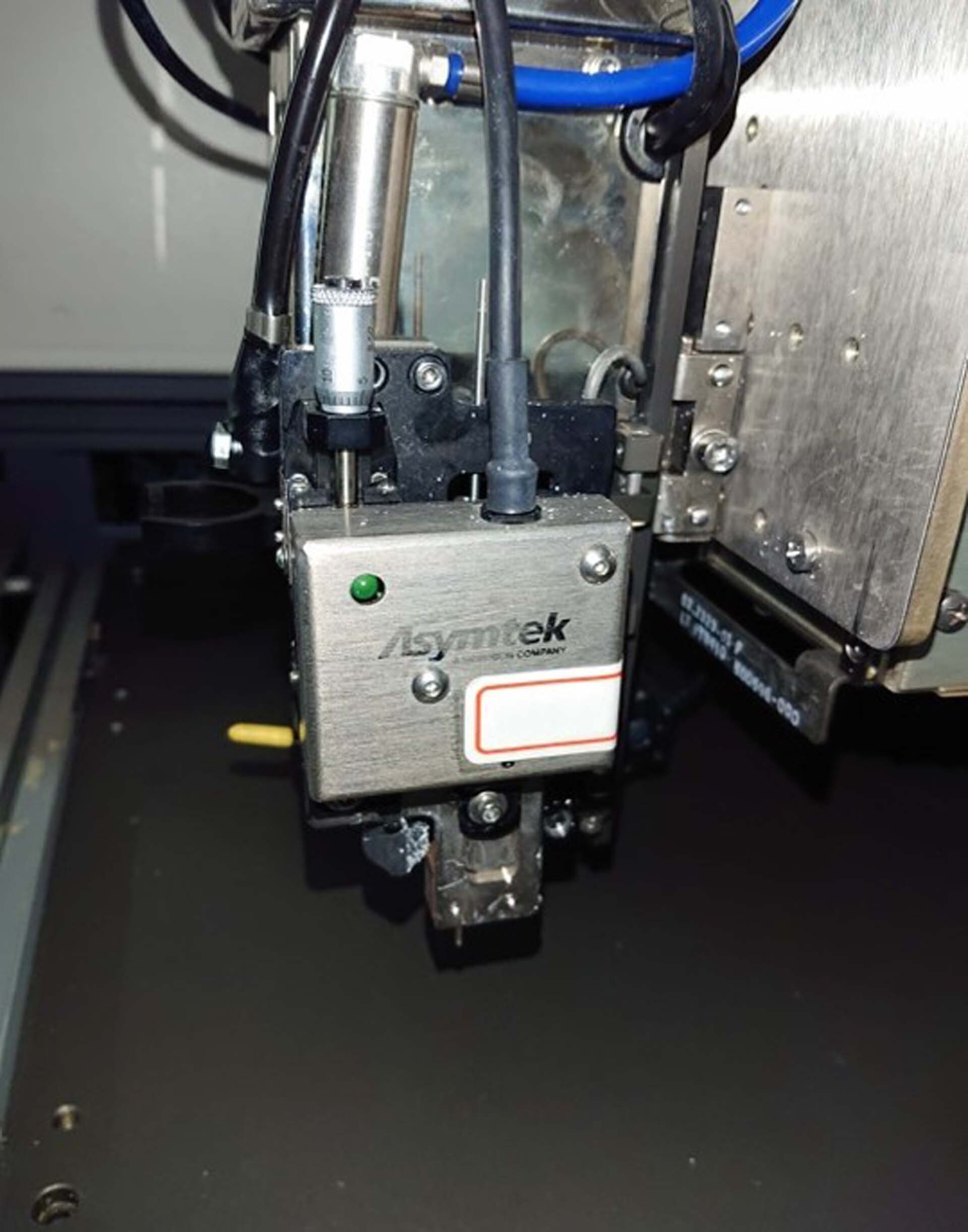

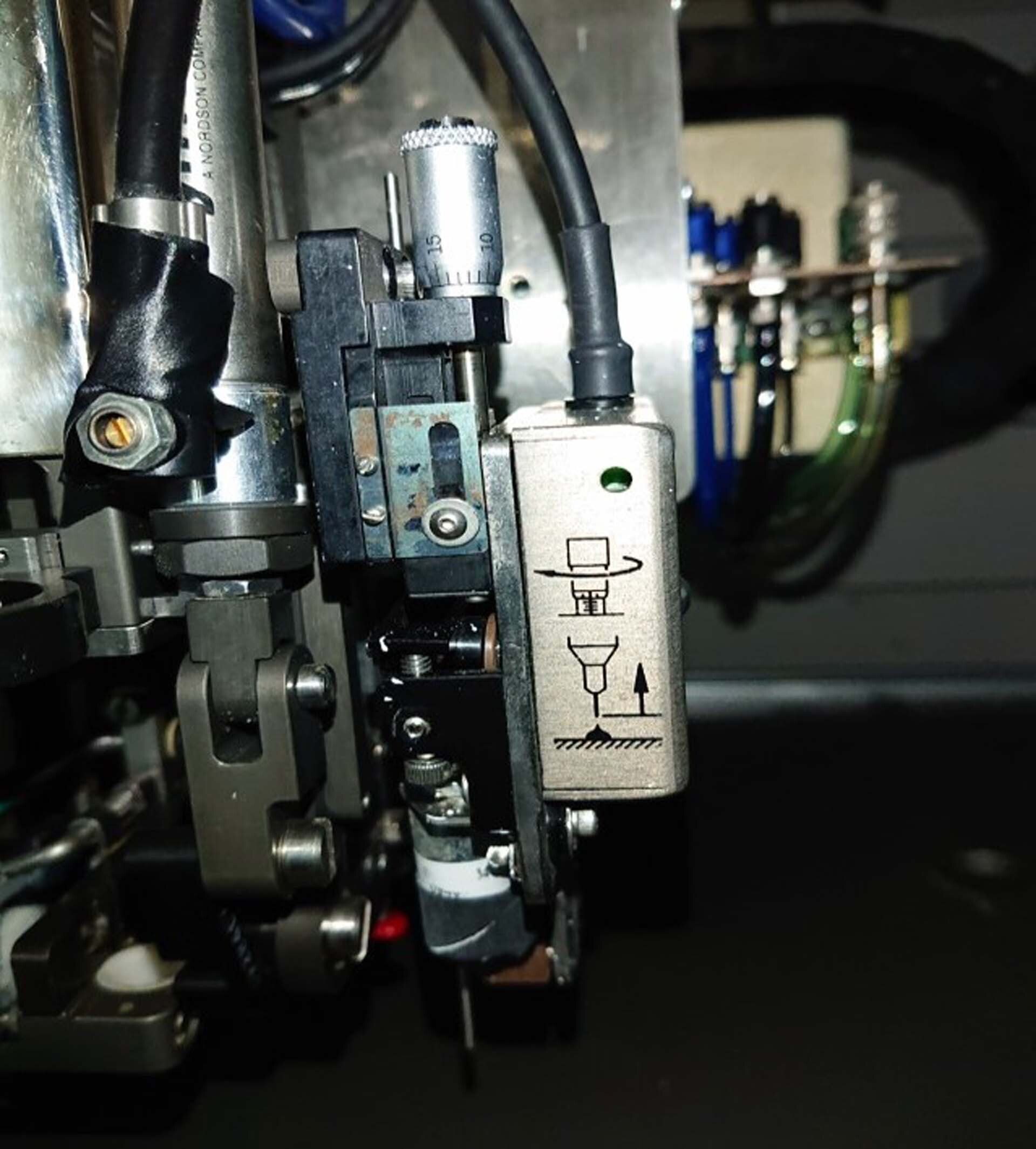

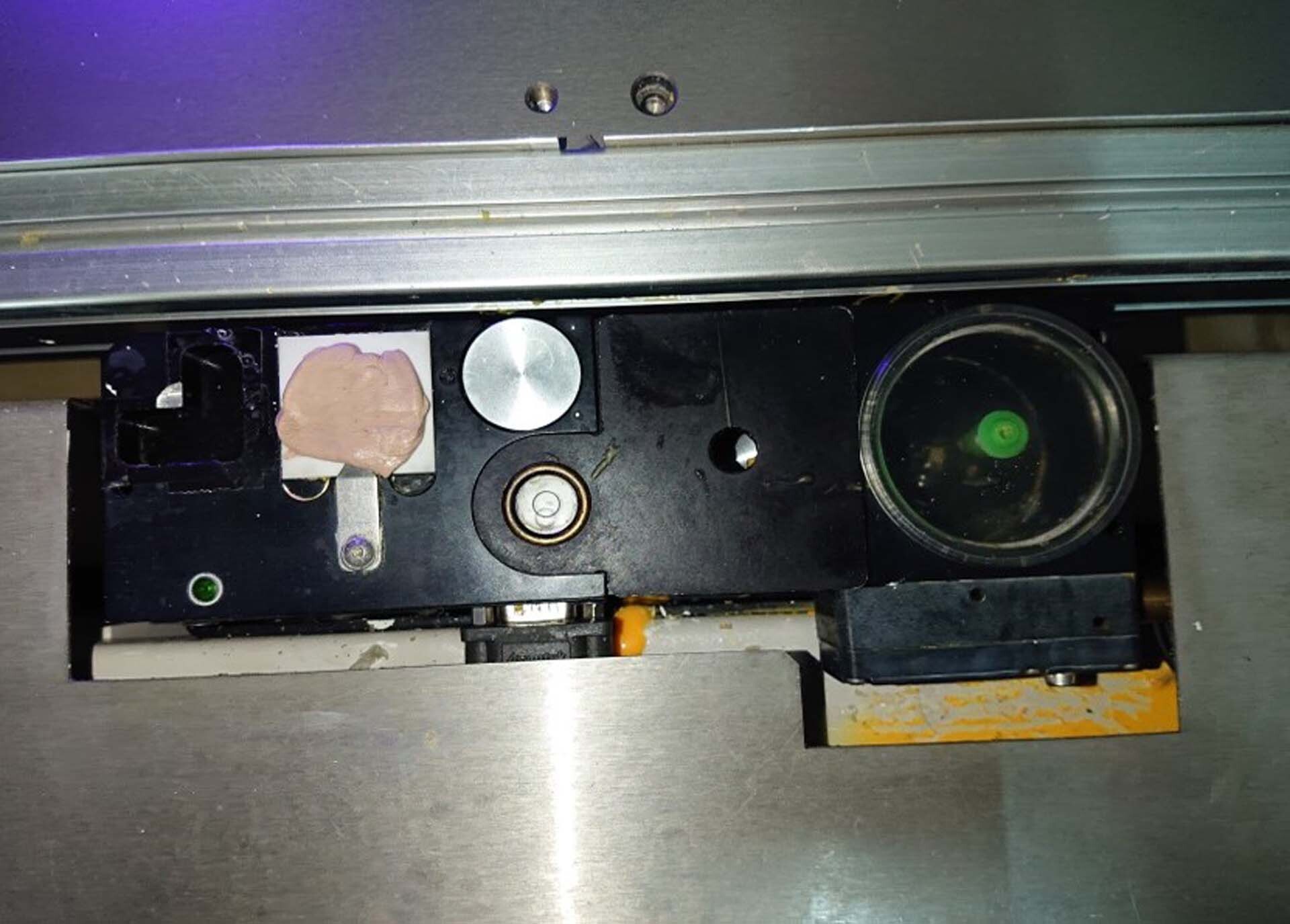

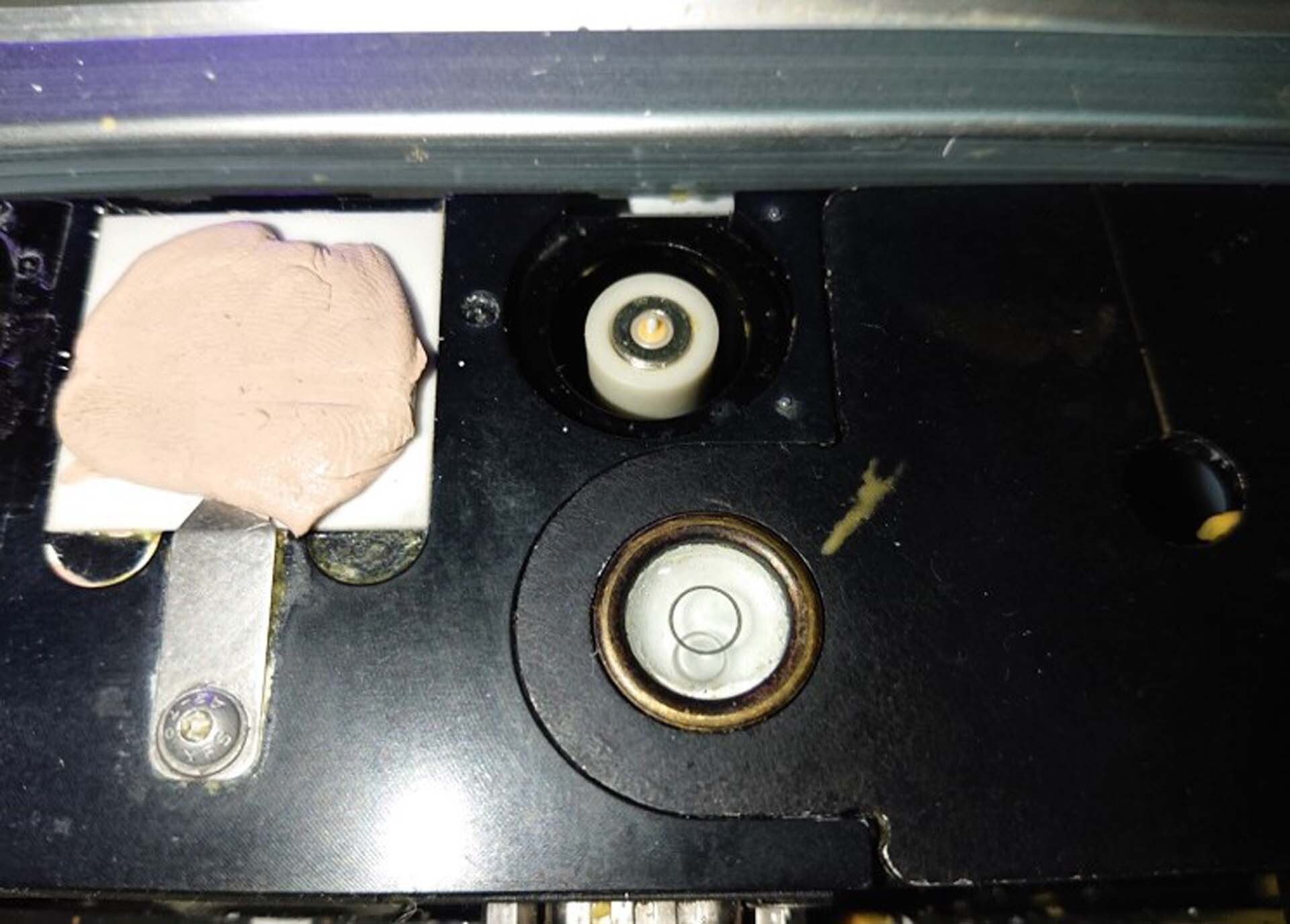

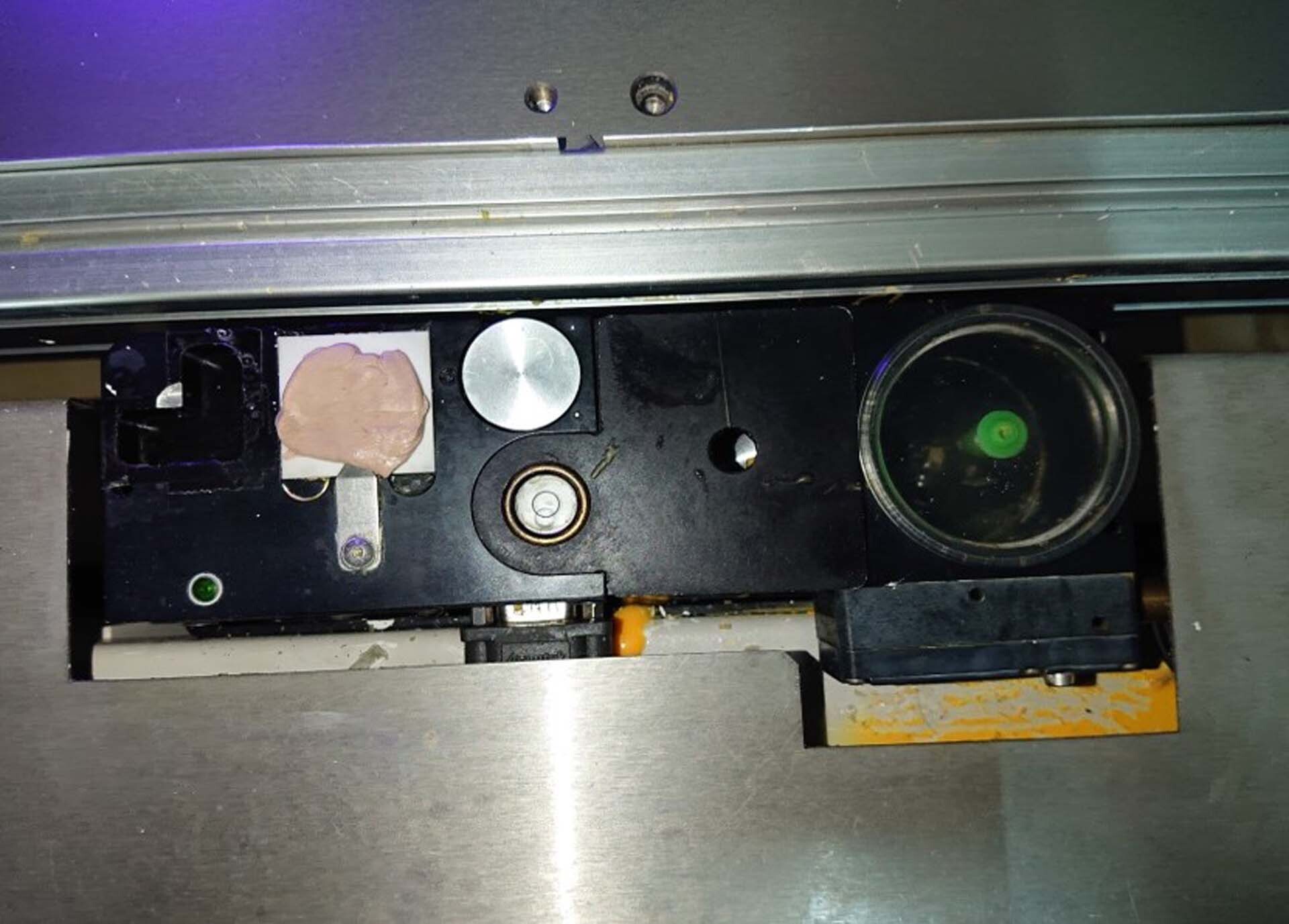

ASYMTEK X-1010 is a precision manufacturing and assembly equipment designed for PC board fabrication and assembly. ASYMTEK X 1010 is a fully automated system that integrates solder paste deposition, precision placement, reflow soldering and dispensing into a single platform. The unit is equipped with eight spindles and two swivel arms to ensure parts are placed accurately within the desired parameters. The machine offers two modes of operation, a low speed front-to-back transfer mode that is ideal for large components and a high speed side-to-side transfer mode to meet fast cycle times. X-1010 is also equipped with a high speed vision tool to inspect critical components, ensuring optimal placement and processing accuracy. The asset also includes a number of advanced process monitoring and control functions, including real-time temperature monitoring, link quality control, and solder flow control. The X-1010PC Board Assembly and Manufacturing Model is capable of handling components from 0201s to up to 55mm. X 1010 is also ready for offline programming, allowing for schedule and project management optimized for process control. In addition, it boasts an open architecture design for easy integration and flexibility in advanced applications. ASYMTEK X-1010 is a reliable and efficient equipment perfect for mission-critical applications with high-density boards, multi-process PCB assembly, and fast cycle times.

There are no reviews yet