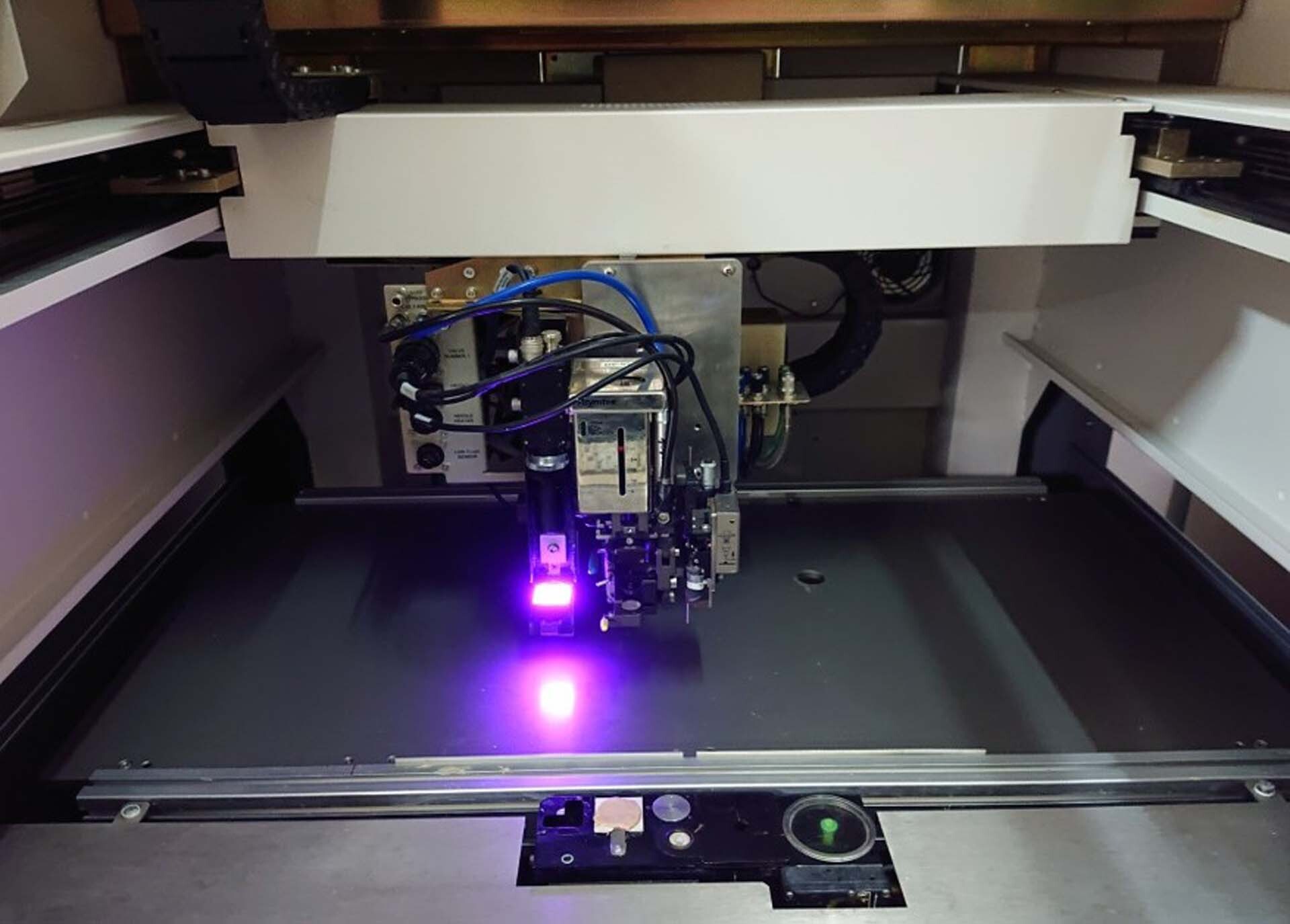

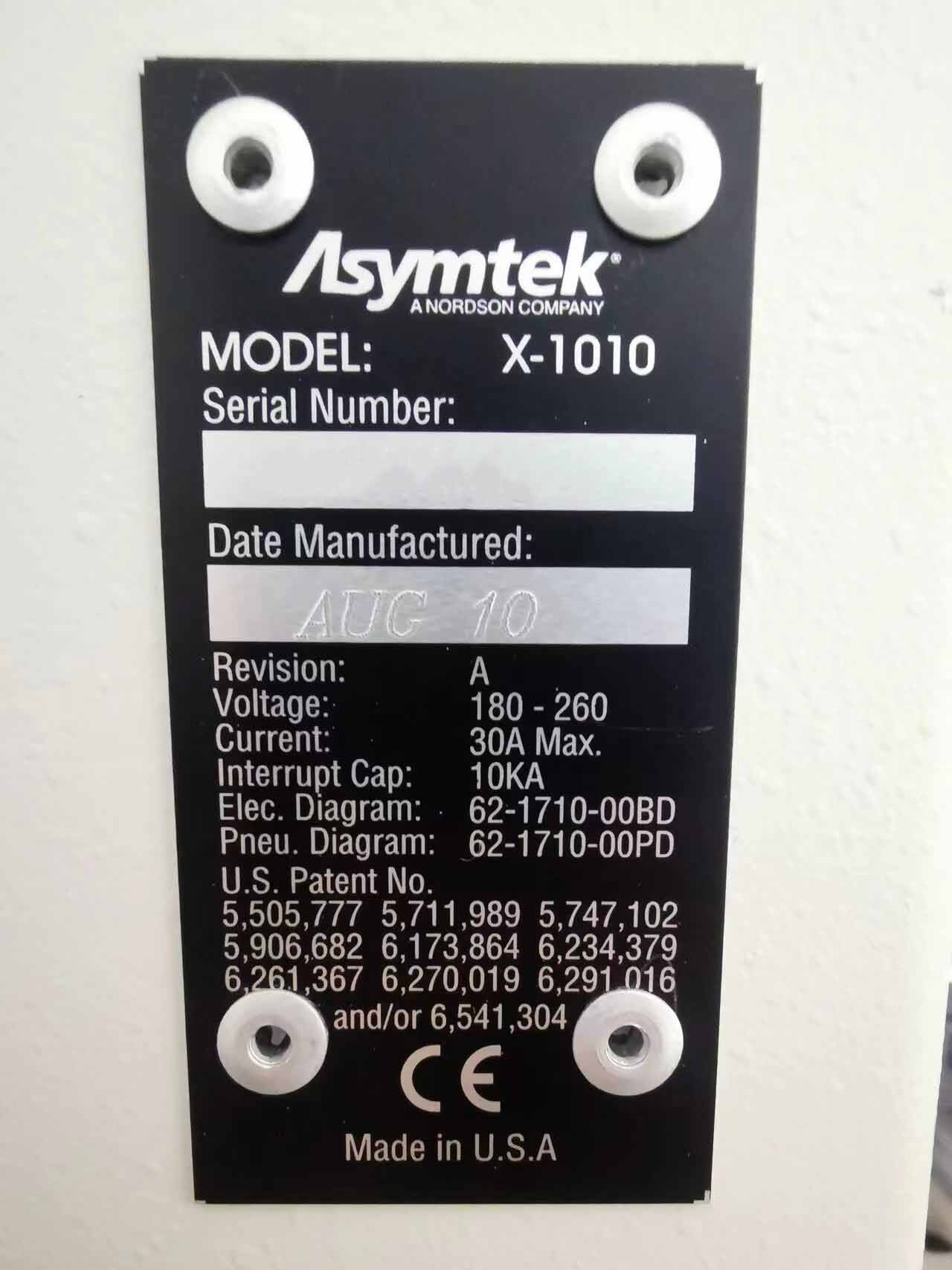

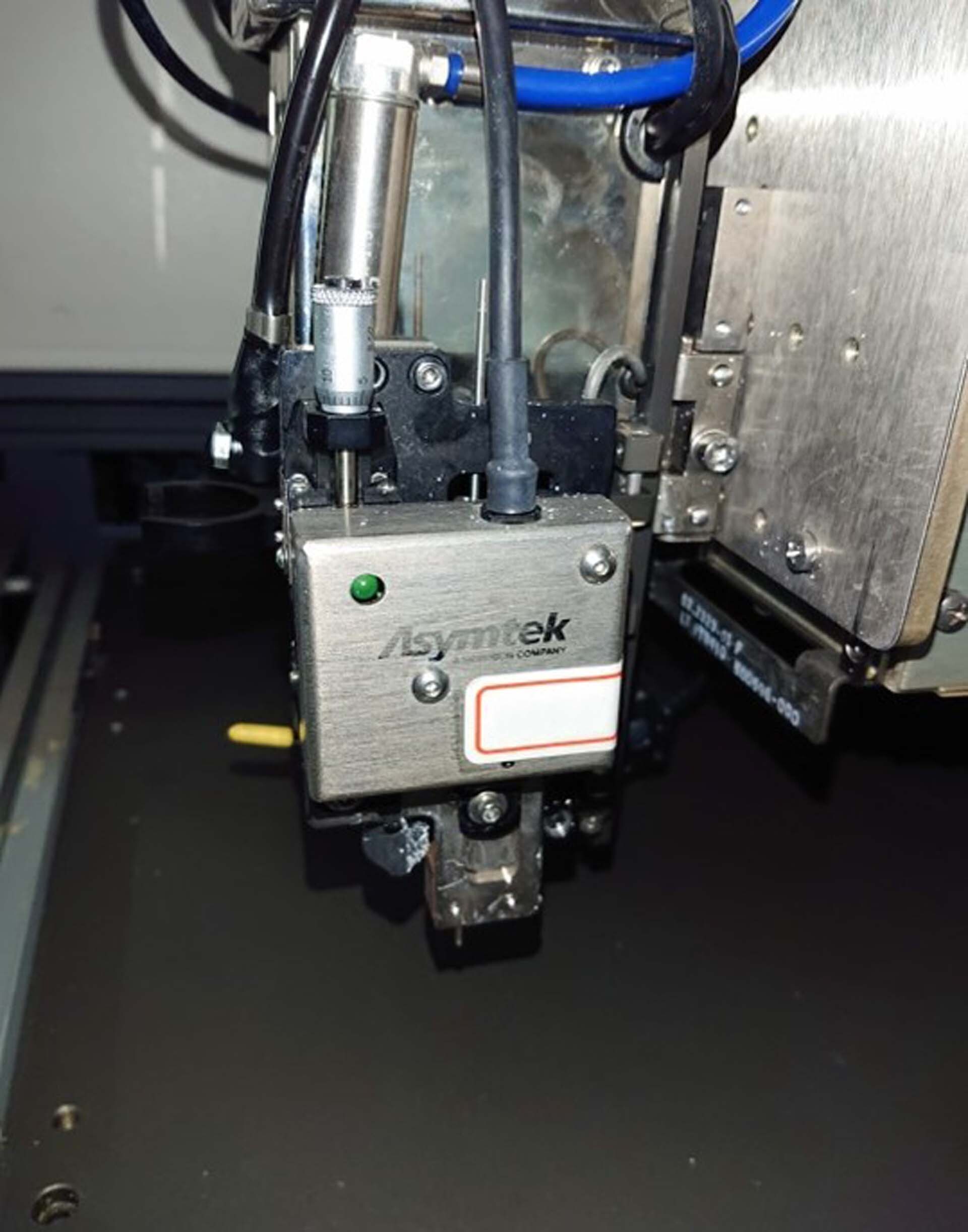

Used ASYMTEK X-1010 #9407899 for sale

URL successfully copied!

Tap to zoom

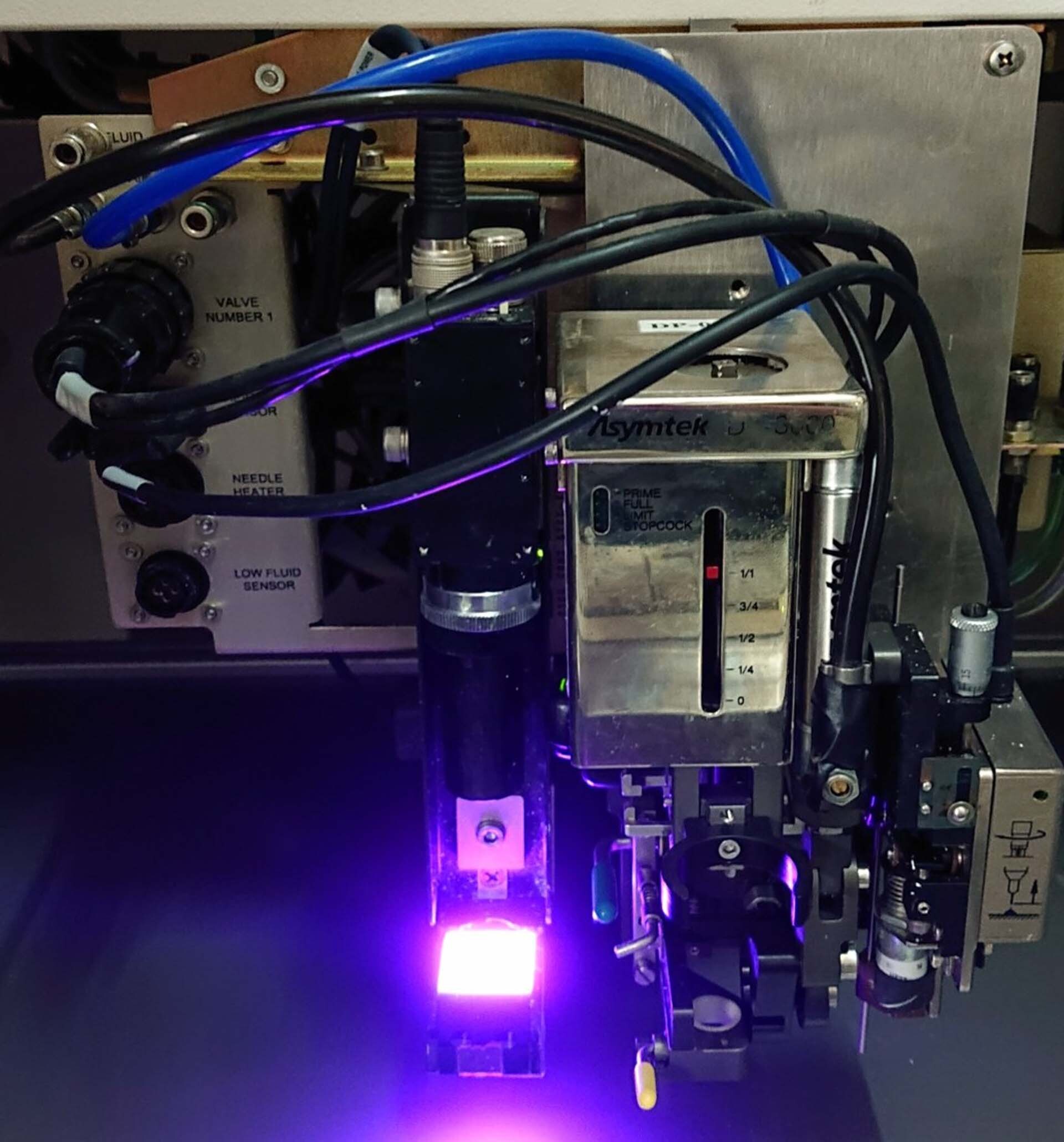

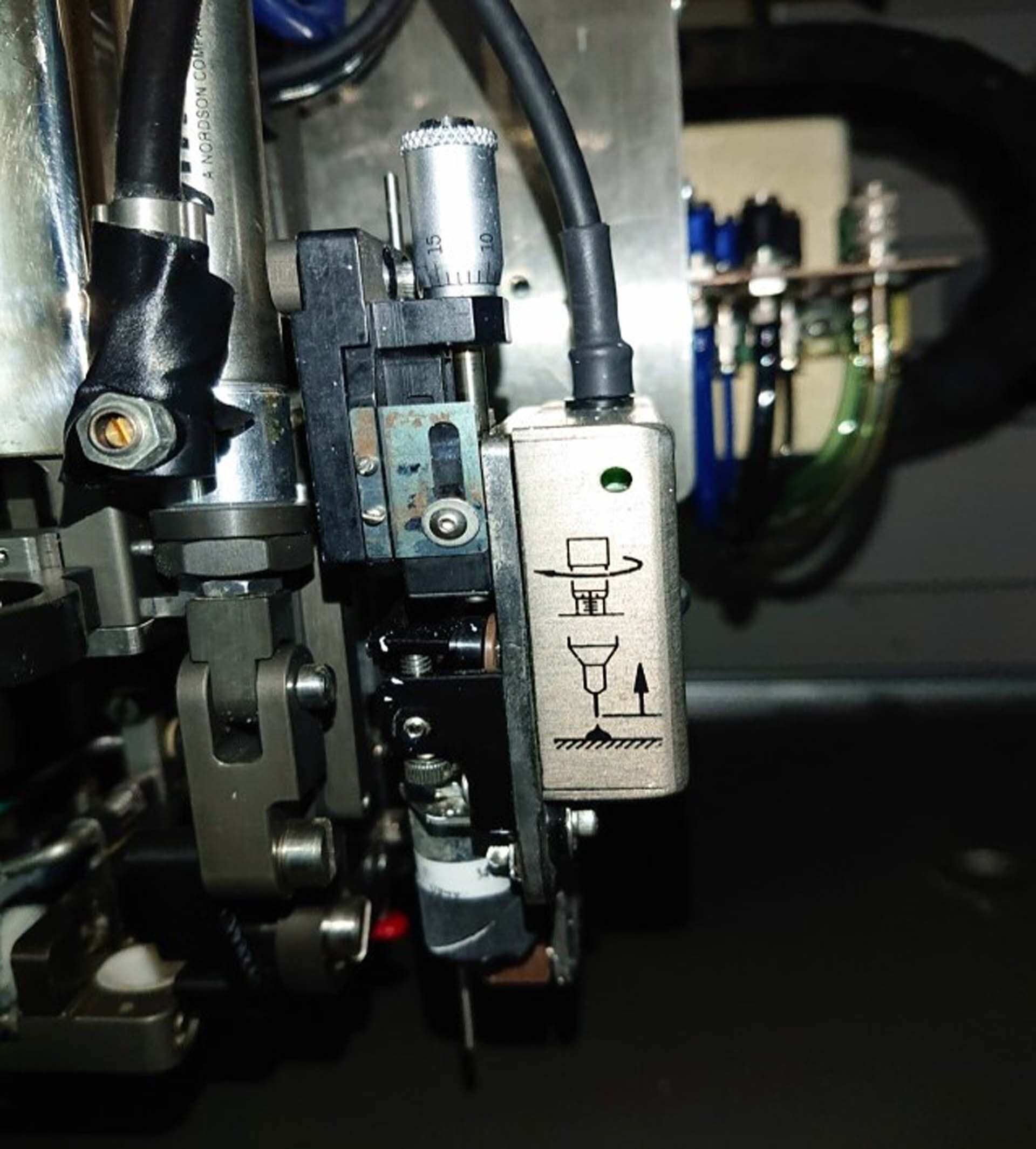

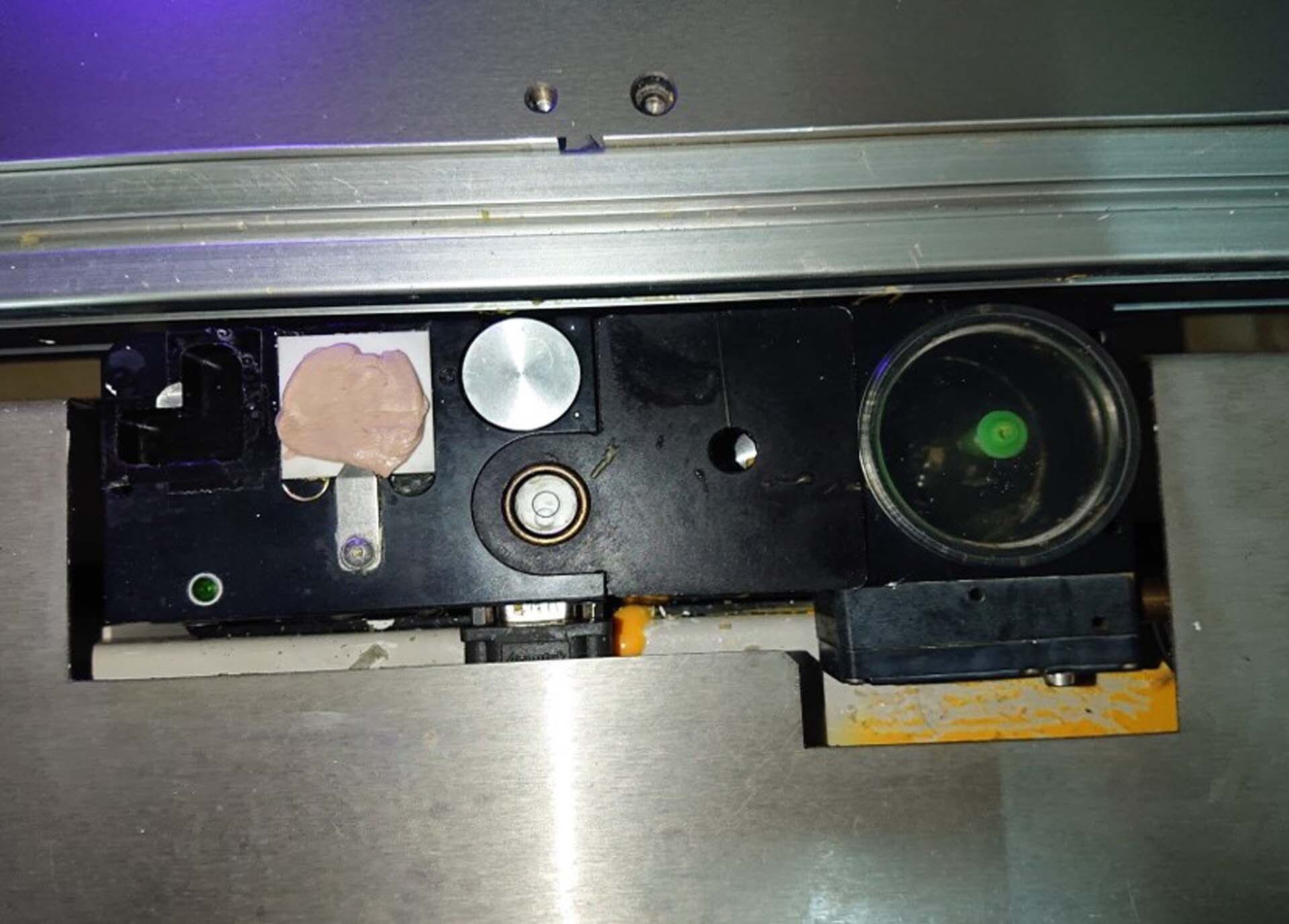

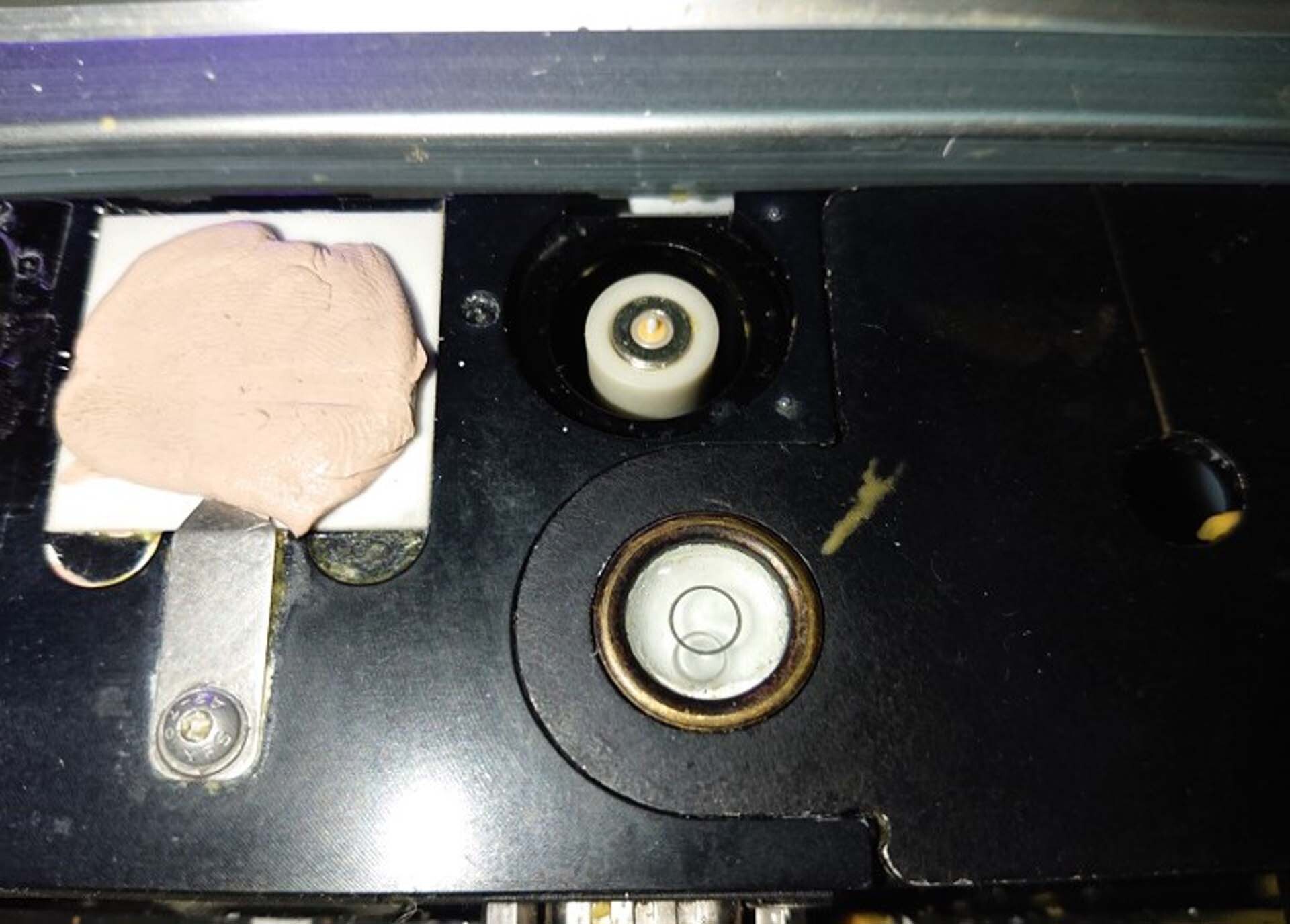

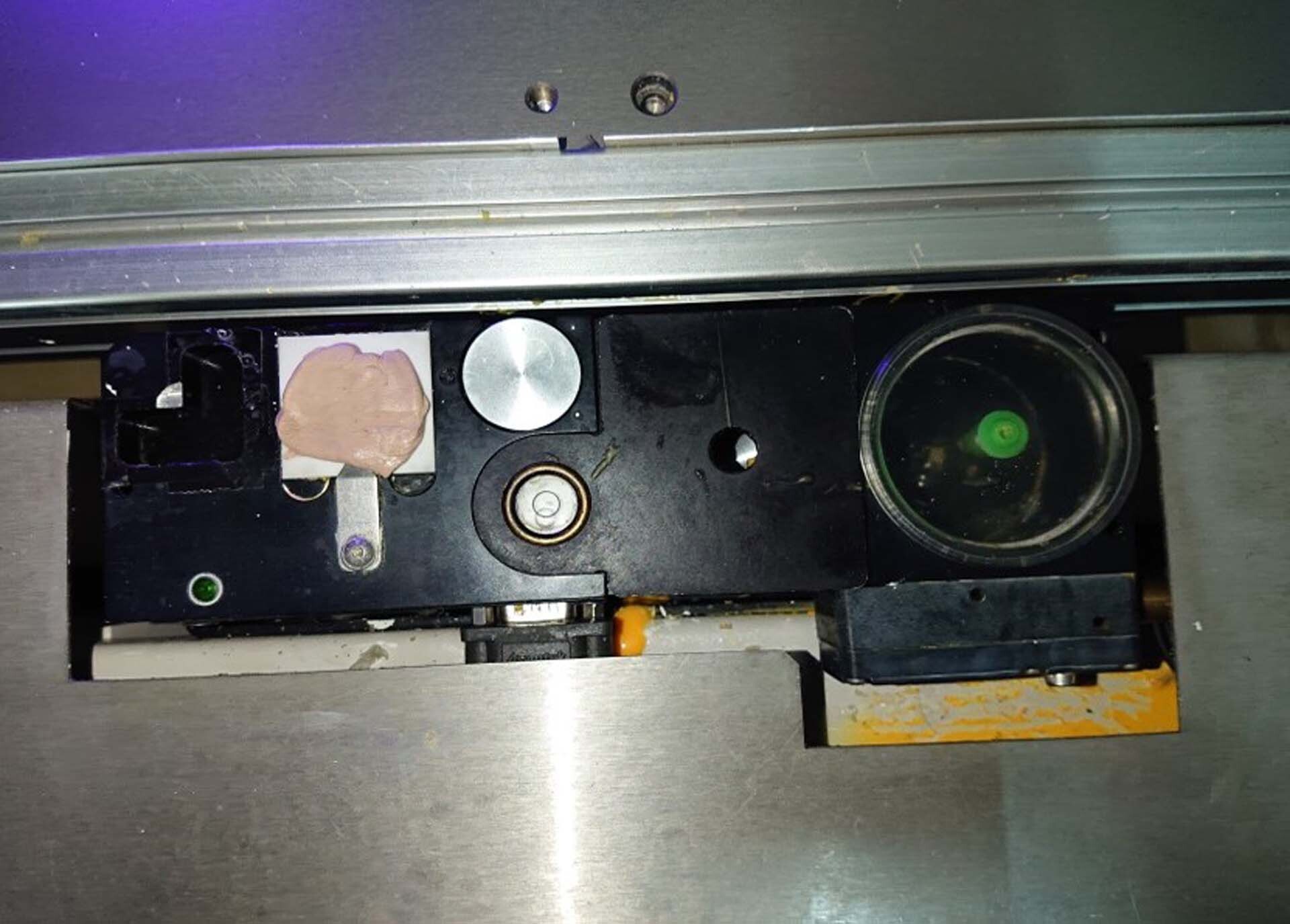

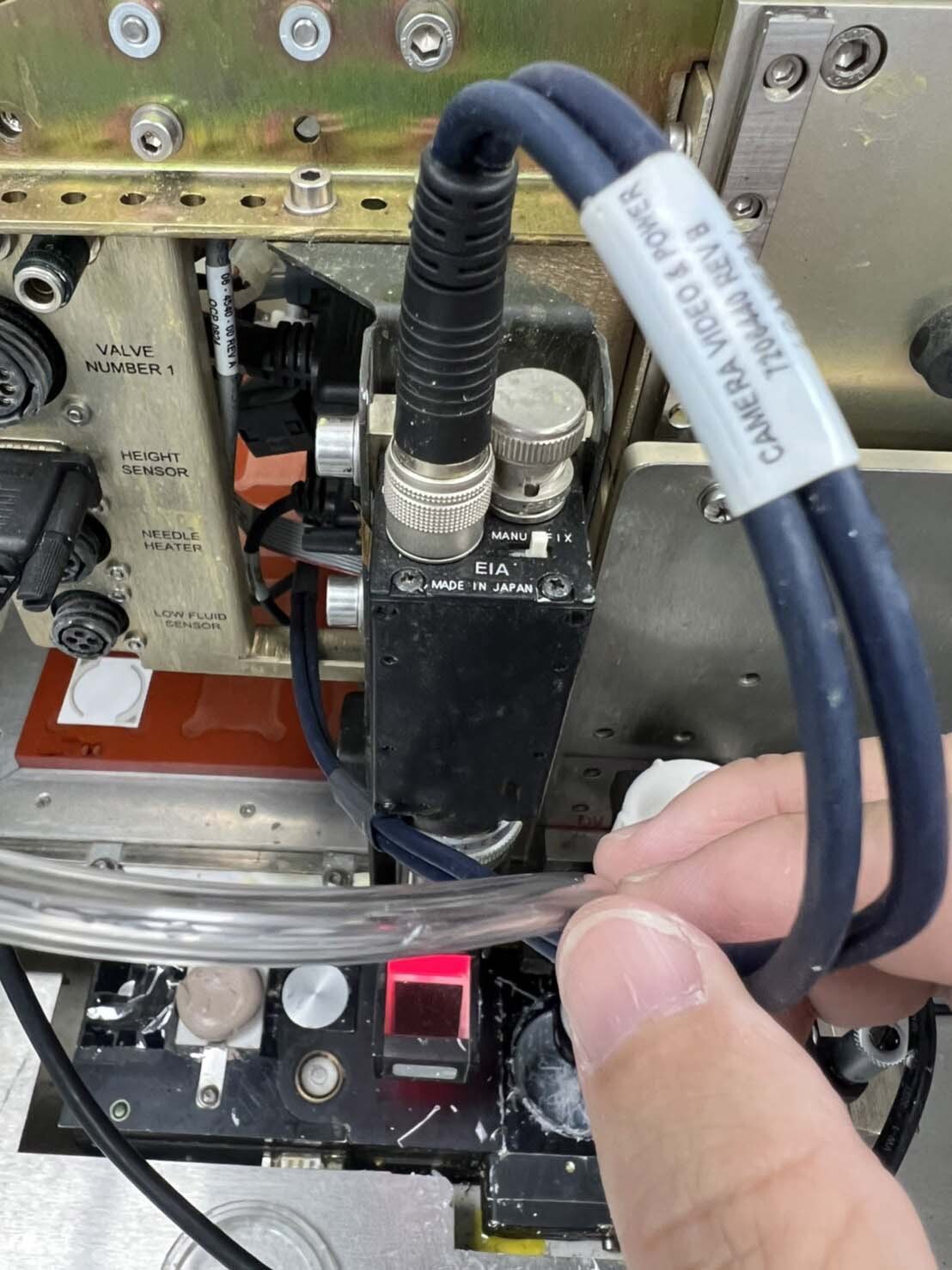

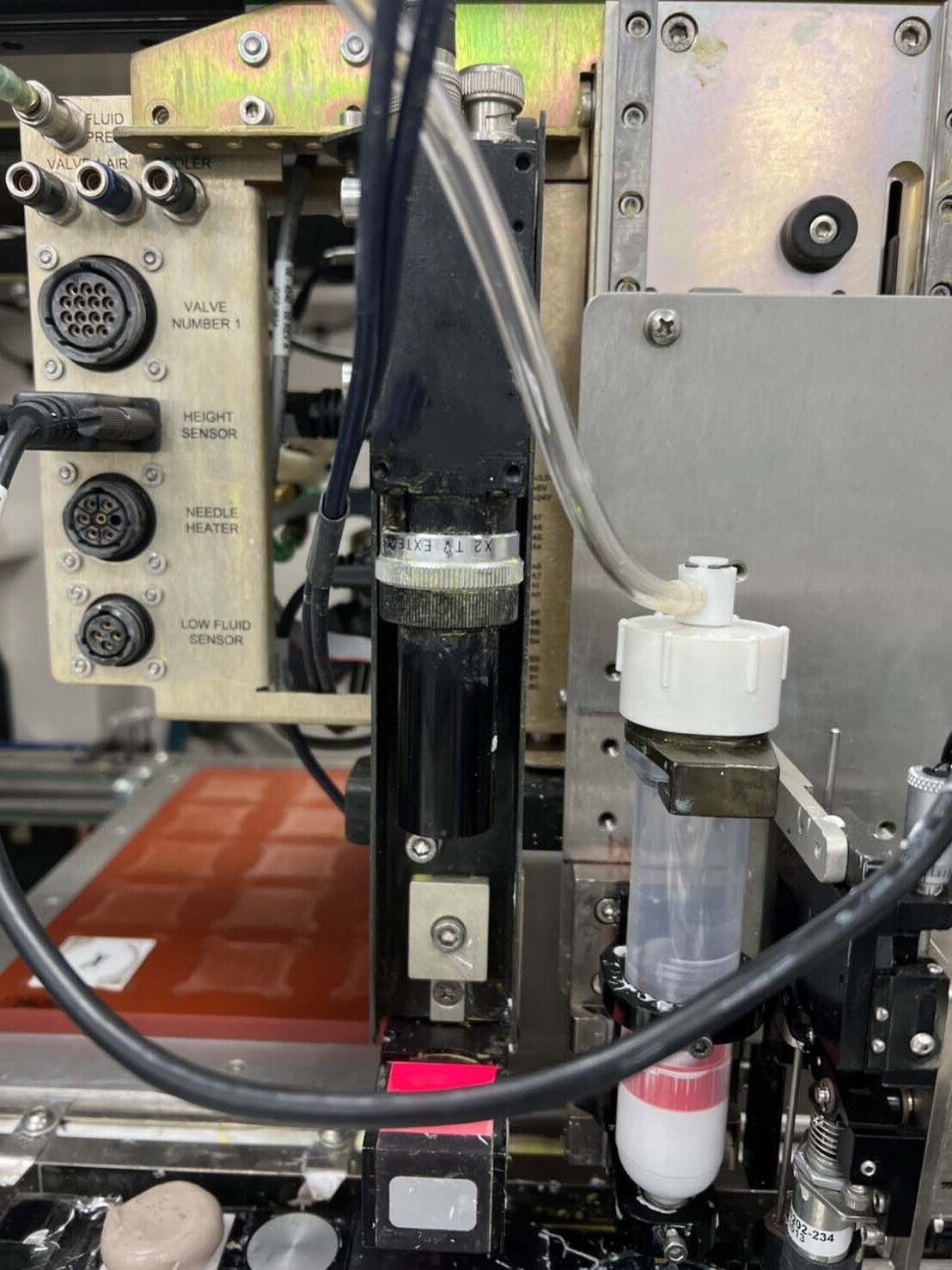

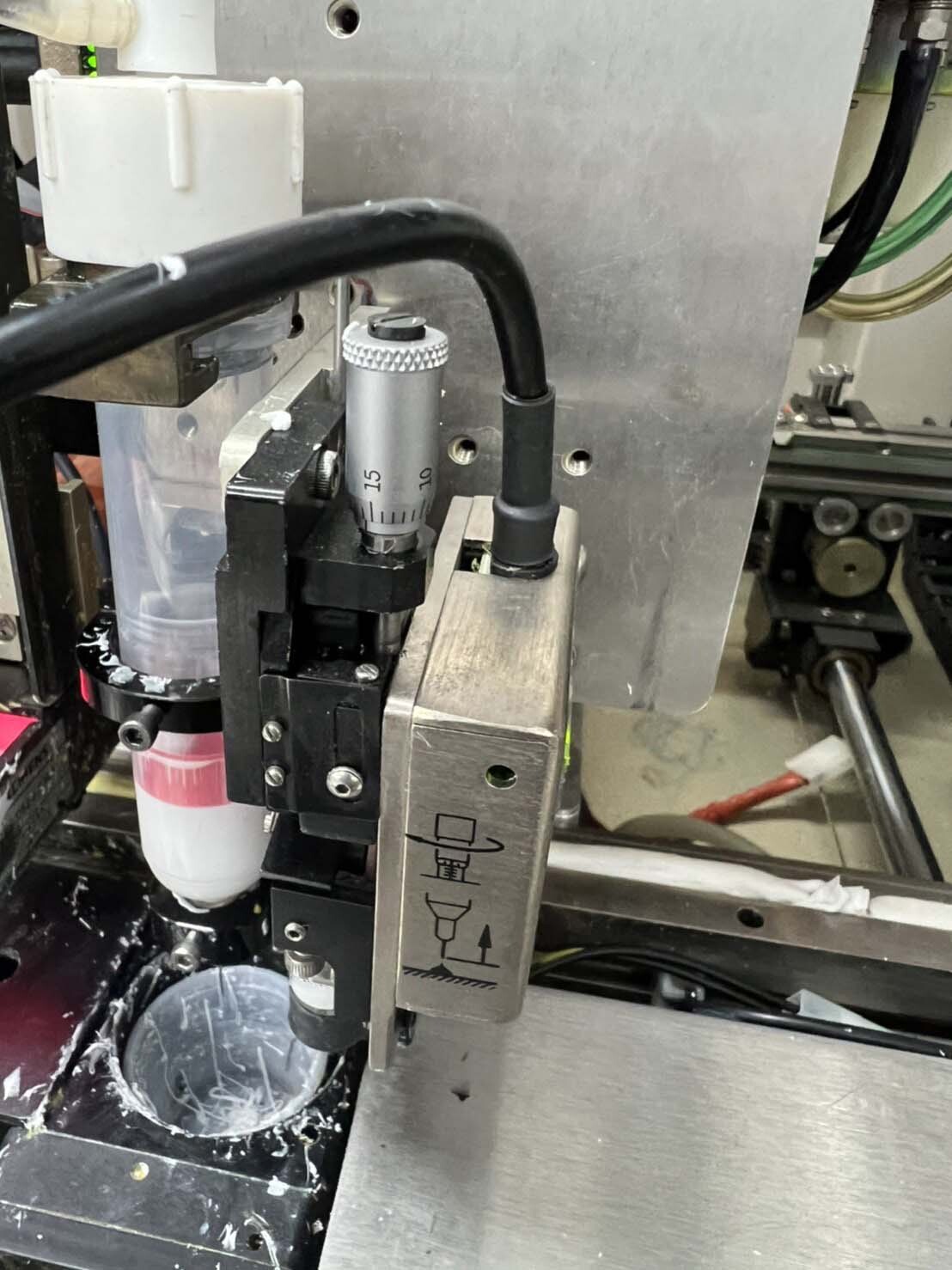

ASYMTEK X-1010 is a revolutionary flex-PCB assembly and manufacturing equipment that offers rapid prototyping and assembly capabilities for a range of different printed circuit board (PCB) sizes. ASYMTEK X 1010 uses a progressive assembly approach that eliminates the need for dedicated setup for up to seven different board sizes. X-1010 features a 10" LCD touchscreen that provides versatile programming and easy access for operators to customize their assembly process. It also includes dual head vision technology, automated board handling and a unique flexibility that gives users the ability to program and run multiple processes in tandem. This allows for rapid batch processing and prototyping of circuit boards with minimal setup. X 1010 is packed with a range of other features that enable users to customize their assembly processes. It comes with a Universal Process Controller (UPC) and offers a range of selectable dispensing processes. This provides ultimate control in both manual and automated manufacturing. It also contains a CCD camera which performs automated inspections of solder joint quality. This can detect and alert operators to any potential faults or defects before the board leaves the manufacturing process. In terms of placement capabilities, ASYMTEK X-1010 offers superior accuracy and speed. An integrated servo-driven vision system positions components with accuracy up to 2 micron positioning accuracy. This allows users to place components quickly and accurately, ensuring their products are always of the highest quality. ASYMTEK X 1010 also comes with an optional solder printer to provide users with solder paste printing capabilities. This provides users with a superior level of control and the ability to adjust various process parameters to ensure quality results on their assemblies. X-1010 offers an efficient and reliable manufacturing unit that ensures circuit boards are assembled quickly and efficiently. The machine is designed with robust reliability and advanced flexibility which can handle up to seven different board sizes at once. It also offers superior placement accuracy and solder paste printing capabilities, making it ideal for rapid prototyping and rapid batch processing of PCBs.

There are no reviews yet